Environmentally friendly flame-retardant polyvinyl chloride composition for drain pipe and preparation method thereof

A technology of flame-retardant polyvinyl chloride and polyvinyl chloride, which is applied in the field of environmentally friendly flame-retardant polyvinyl chloride compositions for drainage pipes and its preparation, can solve the problems of reduced performance of pipes and difficulties in meeting the fire safety requirements of building materials, and achieve The effects of retarding combustion, high-efficiency thermal stabilization, good flame-retardant and smoke-suppressing properties and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

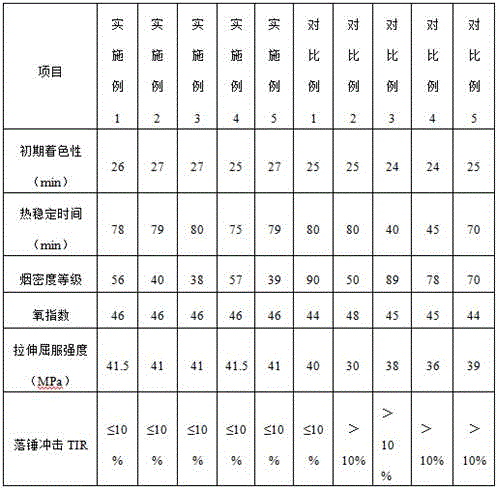

Examples

Embodiment 1

[0028] An environmentally friendly flame-retardant polyvinyl chloride composition for drain pipes, which consists of the following components in parts by mass:

[0029] 100 parts of polyvinyl chloride; 5 parts of compound zinc-based flame retardant heat stabilizer; 0.3 parts of stearic acid, 0.6 parts of oxidized polyethylene wax, 0.9 parts of calcium stearate; 6 parts of chlorinated polyethylene; 2.5 parts of titanium dioxide; 15 parts of calcium carbonate.

[0030] Among them, the compound zinc-based flame retardant heat stabilizer is composed of the following components: 100 parts of zinc phosphite; 8 parts of tris(2-hydroxyethyl) isocyanurate, 4 parts of dibenzoylmethane; tripentaerythritol phosphorous acid 10 parts of ester, 60 parts of nano hydrotalcite, 30 parts of halloysite.

[0031] After mixing the above raw materials evenly, they are extruded into tubes through an extruder.

Embodiment 2

[0033] An environmentally friendly flame-retardant polyvinyl chloride composition for drain pipes, which consists of the following components in parts by mass:

[0034] 100 parts of polyvinyl chloride; 2 parts of compound zinc-based flame retardant heat stabilizer; 0.5 parts of stearic acid, 1.0 parts of oxidized polyethylene wax; 0.5 parts of titanium dioxide; 60 parts of heavy calcium carbonate.

[0035] Among them, compound zinc-based flame retardant heat stabilizer: 100 parts of zinc phosphite; 8 parts of tris(2-hydroxyethyl) isocyanurate, 2 parts of dibenzoylmethane; 10 parts of tripentaerythritol phosphite, nano 35 parts of hydrotalcite, 15 parts of halloysite.

[0036] After mixing the above raw materials evenly, they are extruded into tubes through an extruder.

Embodiment 3

[0038] An environmentally friendly flame-retardant polyvinyl chloride composition for drain pipes, which consists of the following components in parts by mass:

[0039] 100 parts of polyvinyl chloride; 10 parts of compound zinc-based flame retardant heat stabilizer; 2.5 parts of oxidized polyethylene wax, 2.5 parts of calcium stearate; 10 parts of chlorinated polyethylene; 5 parts of titanium dioxide.

[0040] Among them, compound zinc-based flame retardant heat stabilizer: 100 parts of zinc phosphite; 18 parts of tris(2-hydroxyethyl) isocyanurate, 12 parts of dibenzoylmethane; 15 parts of tripentaerythritol phosphite, 70 parts of hydrotalcite, 40 parts of halloysite.

[0041] After mixing the above raw materials evenly, they are extruded into tubes through an extruder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com