Preparation method of energy-saving and environment-friendly special cleaning agent for medical appliances

A medical device, energy-saving and environment-friendly technology, applied in the direction of chemical instruments and methods, detergent compounding agents, detergent compositions, etc., can solve problems such as shortened service life, impact on cleaning effect, rusting of instruments, etc., to avoid damage and reduce Effects of surface tension and strong detergency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

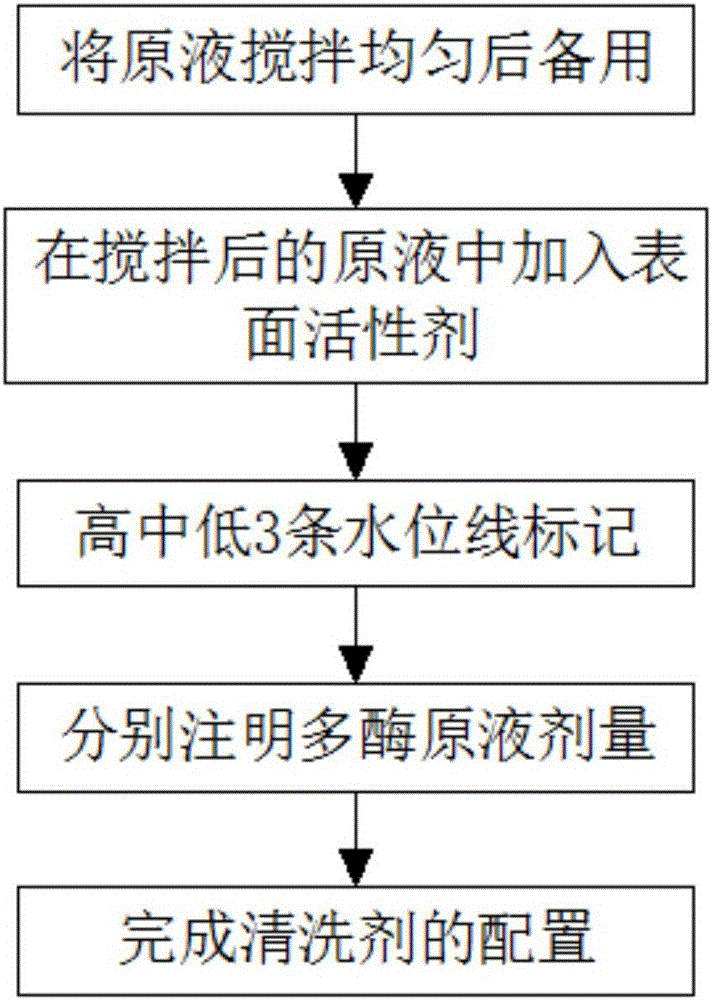

Image

Examples

Embodiment 1

[0017] A method for preparing a special cleaning agent for energy-saving and environment-friendly medical equipment, the specific steps of the preparation method for the special cleaning agent for energy-saving and environment-friendly medical equipment are as follows:

[0018] Protease 25%, lipase 10%, carbohydrase 8%, amylase 12%, sodium hydroxide 3%, potassium pyrophosphate 5%, sodium tripolyphosphate 3%, alkylphenol polyoxyethylene ether 10% by weight % and 80% of deionized water are evenly stirred and mixed with a stainless steel mixer, so that each proportioning material is fully reacted and mixed, stirred evenly for later use, and tested in real time by PH test paper. 25% protease, 10% lipase, 8% carbohydrase and 12% amylase were first placed in a glass vessel containing 80% deionized water, stirred evenly in advance, and then added 3 % sodium hydroxide, 5% potassium pyrophosphate, 3% sodium tripolyphosphate and 10% alkylphenol polyoxyethylene ether and stir evenly;

...

Embodiment 2

[0024] A method for preparing a special cleaning agent for energy-saving and environment-friendly medical equipment, the specific steps of the preparation method for the special cleaning agent for energy-saving and environment-friendly medical equipment are as follows:

[0025] Protease 30%, lipase 15%, carbohydrase 15%, amylase 18%, sodium hydroxide 9%, potassium pyrophosphate 7%, sodium tripolyphosphate 6%, alkylphenol polyoxyethylene ether 15% by weight % and 90% of deionized water are evenly stirred with a stainless steel mixer, and then set aside after stirring evenly, and the pH value is adjusted to 1.6 with sodium hydroxide. Amylase was placed in a glass vessel filled with 90% deionized water, and after stirring evenly in advance, 9% sodium hydroxide, % potassium pyrophosphate, 6% sodium tripolyphosphate and 15% alkylphenol polyoxyethylene ether were added and stir well;

[0026] Add a surfactant to the liquid raw material after stirring, stir again, put it aside after...

Embodiment 3

[0031] A method for preparing a special cleaning agent for energy-saving and environment-friendly medical equipment, the specific steps of the preparation method for the special cleaning agent for energy-saving and environment-friendly medical equipment are as follows:

[0032] Protease 28%, lipase 13%, carbohydrase 12%, amylase 15%, sodium hydroxide 6%, potassium pyrophosphate 6%, sodium tripolyphosphate 4%, alkylphenol polyoxyethylene ether 13% by weight % and 85% of deionized water are evenly stirred with a stainless steel mixer, and then set aside after stirring evenly, and the pH value is adjusted to 1.2 with sodium hydroxide. Amylase was placed in a glass vessel filled with 85% deionized water, and after stirring evenly in advance, 6% sodium hydroxide, 6% potassium pyrophosphate, 4% sodium tripolyphosphate and 13% alkylphenol polyoxyethylene were added Ether and stir evenly, the cleaning agent prepared by the above-mentioned raw material ratio has strong cleaning power; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com