Production method comprehensively utilizing high-zinc cobalt raw materials

A production method and technology for raw materials, which are applied in the production field of comprehensive utilization of high-zinc-cobalt raw materials, can solve the problems of difficult operation of metal elements, complex organic phase components, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] A production method for comprehensively utilizing high-zinc-cobalt raw materials, comprising the following steps: first step, zinc content in high-zinc-cobalt raw materials: 5%-20%, cobalt content: 5-10%, zinc-cobalt content ratio: 0.5:4 , Other impurities 0.001%-10%.

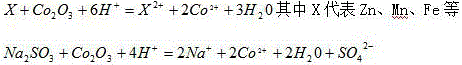

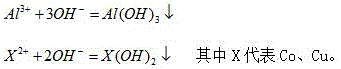

[0016] The high-zinc and cobalt raw materials are reductively leached, and soluble valuable metals such as zinc and cobalt enter the solution, and the solid-liquid separation; the second step: after the solid-liquid separation, the solution is removed by the yellow sodium iron vanadium method, and the pH value is adjusted to 4.7± 0.2, the aluminum in the solution is precipitated and removed in the form of aluminum hydroxide, and solid-liquid separation; the third step, the solution enters the P507 extraction tank, uses 20%-30% P507 extraction agent, and adds liquid alkali to control the saponification rate of 50-60 %, the Zn in the solution 2+ extracted into the organic phase, the organic phase was wash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com