Diamond/diamond-like multilayer composite coating and preparation method thereof

A diamond coating and multi-layer composite technology, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems that cannot be solved such as coating stress and coating toughness, and achieve favorable coating stress , solve the effect of high stress and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

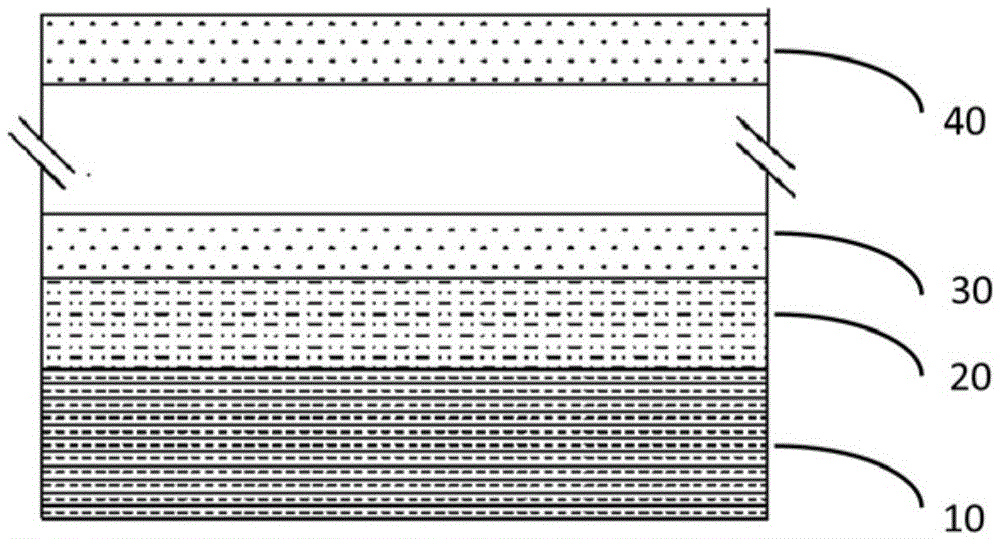

[0017] Specifically, the embodiment of the present invention provides a method for preparing a diamond / diamond-like multilayer composite coating, comprising the following steps:

[0018] S01. Provide a substrate, carry out surface pretreatment on the substrate and load it into a furnace;

[0019] S02. Under vacuum conditions, feed methane and carry out the first coating process, and deposit a diamond coating on the surface of the substrate, wherein the heating temperature of the first coating process is 2000-2500 ° C, and the substrate temperature is 600-1000°C, the methane concentration is 0.5-3%;

[0020] S03. Under vacuum conditions, adjust the heating temperature and methane concentration to carry out the second coating process, and deposit a diamond-like coating on the surface of the diamond coating, wherein the heating temperature of the second coating process is 1500-2200 ° C, The substrate temperature is 400-800°C, and the methane concentration is 2-5%;

[0021] S04....

Embodiment 1

[0041] With WC-6%Co cutter as substrate in this embodiment 1, the method for preparing diamond / diamond-like multilayer composite coating on described substrate comprises the steps:

[0042] S11. Provide a substrate, carry out surface pretreatment on the substrate and load it into a furnace; specifically,

[0043] S111. Put the WC-Co tool into the acetone solution for ultrasonic cleaning for 30 minutes, and dry it in a constant temperature drying oven at 60°C for 10 minutes;

[0044] S112. Put the cleaned carbide tool into K 3 [Fe(CN) 6 ]+KOH+H 2 O (wt%=1:1:10) alkali mixed solution was ultrasonicated for 10min, and distilled water was taken out for cleaning, and then washed with H 2 SO 4 +H 2 o 2 (vol%=1:10) Soak for 10s, take out distilled water to wash, dry at constant temperature at 60°C, and dry for 20min;

[0045] S113. Put the pretreated cutter into a diamond suspension with a mass fraction of 10% and sonicate for 30 minutes, take out distilled water for cleaning,...

Embodiment 2

[0052] With TiC-Co cutter as substrate in this embodiment 2, the method for preparing diamond / diamond-like multilayer composite coating on described substrate comprises the steps:

[0053] S21. Provide a substrate, carry out surface pretreatment on the substrate and load it into a furnace; specifically,

[0054] S211. Put the TiC cutter into an acetone solution for ultrasonic cleaning for 20 minutes, and dry in a constant temperature drying oven at 70°C for 10 minutes;

[0055] S212. Put the cleaned carbide tool into K 3 [Fe(CN) 6 ]+KOH+H 2 O (wt%=1:1:10) alkali mixed solution was ultrasonicated for 15min, and distilled water was taken out for cleaning, and then washed with H 2 SO 4 +H 2 o 2 (vol%=1:10) Soak for 15s, take out distilled water and wash, dry at constant temperature at 60°C, and dry for 20min;

[0056] S213. Put the pretreated cutter into 8% diamond suspension by mass fraction and sonicate for 45 minutes, take out the distilled water for cleaning, and blow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com