Production method for adhesive-free straw density board

A production method and density board technology, applied in the field of board manufacturing, can solve the problems of reduced wood supply, low cost and price, and low strength, and achieve the effects of simple production process, no formaldehyde release, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

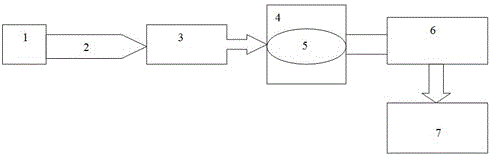

[0018] See figure 1 , A production method of no-adhesive straw density board, the specific steps are as follows:

[0019] 1) The wheat straw is evenly cut into small sections with a length of 8cm through the grass cutter 1;

[0020] 2) The short sections of wheat straw stalks are pre-soaked in the alkaline extractant solution through the reaction chamber 2 and placed for 1 hour, so that the medicinal solution can fully penetrate into the straws, so that the cellulose, hemicellulose and lignin can be fully dissolved and separated;

[0021] 3) The wheat straw stalks are divided into filaments and broomed by the refining machine 3 which integrates, rubbing, pressing and dividing, and refined into complete fine fibers, and then the fibers are transported to the hanger 4;

[0022] 4) It is then flattened and formed by the rotary screen 5, and then formed by hot pressing and drying by the hot press 6 to form a plate, and finally finished and shaped by the sawing machine 7.

[0023] The basic...

Embodiment 2

[0025] See figure 1 , A production method of no-adhesive straw density board, the specific steps are as follows:

[0026] 1) The wheat straw is evenly cut into small sections with a length of 8.5cm through the grass cutter 1;

[0027] 2) The short sections of wheat straw stalks are pre-soaked in the alkaline extractant solution through the reaction chamber 2 and placed for 1.2h, so that the medicinal solution can fully penetrate into the straws, so that the cellulose, hemicellulose and lignin can be fully dissolved and separated;

[0028] 3) The wheat straw stalks are divided into filaments and broomed by the refining machine 3 which integrates, rubbing, pressing and dividing, and refined into complete fine fibers, and then the fibers are transported to the hanger 4;

[0029] 4) It is then flattened and formed by the rotary screen 5, and then formed by hot pressing and drying by the hot press 6 to form a plate, and finally finished and shaped by the sawing machine 7.

[0030] The basic...

Embodiment 3

[0032] See figure 1 , A production method of no-adhesive straw density board, the specific steps are as follows:

[0033] 1) The wheat straw is evenly cut into small pieces with a length of 9cm through the grass cutter 1;

[0034] 2) The short section of wheat straw straw is pre-soaked in the alkaline extractant solution through the reaction chamber 2 and placed for 1.5h, so that the drug solution can fully penetrate into the straw, so that the cellulose, hemicellulose and lignin can be fully dissolved and separated;

[0035] 3) The wheat straw stalks are divided into filaments and broomed by the refining machine 3 which integrates, rubbing, pressing and dividing, and refined into complete fine fibers, and then the fibers are transported to the hanger 4;

[0036] 4) It is then flattened and formed by the rotary screen 5, and then formed by hot pressing and drying by the hot press 6 to form a plate, and finally finished and shaped by the sawing machine 7.

[0037] The basic refining age...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com