Coke oven raw gas ascending pipe heat exchanger

A waste gas and heat exchanger technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of incapable of cooling medium leakage, difficult to find heat exchanger damage, coking furnace body damage and other problems , to achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

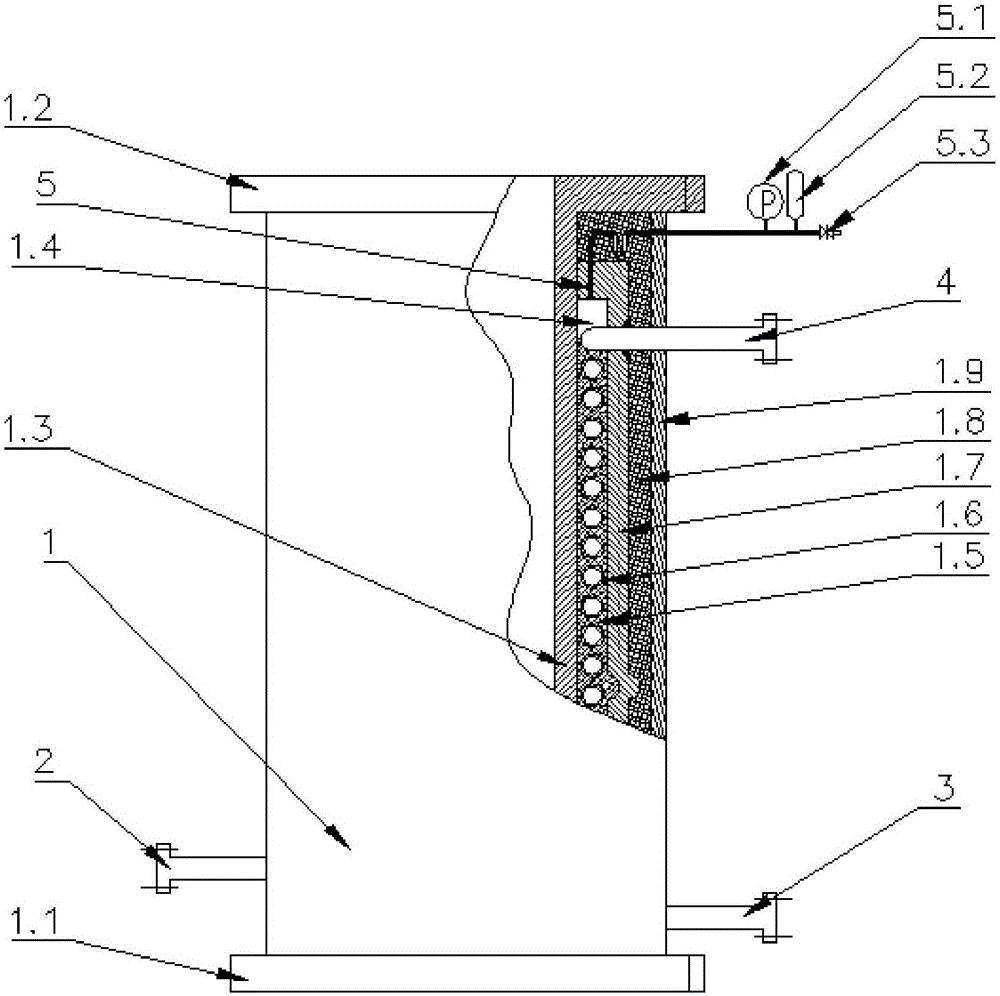

[0023] This embodiment provides a coke oven raw gas riser heat exchanger, which consists of a heat exchanger inner shell, an inner interlayer, a middle shell, an insulation layer, an outer shell, a heat exchange tube, an air guide tube, and a heat exchanger connecting flanges up and down composition. The heat exchanger is connected with the coke oven bridge tube and the outlet of the carbonization chamber through the upper and lower connecting flanges. The inner shell and the middle shell are connected by welding, and the sealing performance is guaranteed to be excellent, and no gas leakage will occur when the electric regulating valve is closed during operation. There is an inner interlayer between the inner shell and the middle shell, and the inner interlayer is filled with a solid heat-conducting medium, which accounts for more than half of the volume of the inner interlayer. According to the thermal expansion of the heat-conducting medium, it is ensured that the heat excha...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that the upper and lower edges of the middle shell in this embodiment are not connected with the inner shell, and the upper and lower edges of the middle shell in this embodiment are sealed and connected with the upper and lower flanges, and, for To ensure the accuracy of measuring the pressure in the inner interlayer, it is necessary to seal the upper and lower edges of the inner shell with the upper and lower flanges.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com