Optical tweezers type optical fiber Raman microprobe and manufacturing method

A Raman probe and optical fiber technology, which is applied in the field of optical tweezers fiber Raman probe production, can solve the problems of inability to intervene in living tissue, difficult living tissue Raman measurement, poor flexibility, etc., and achieves small size and measurement process. Stable, high spatial resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention is described in more detail below in conjunction with accompanying drawing example:

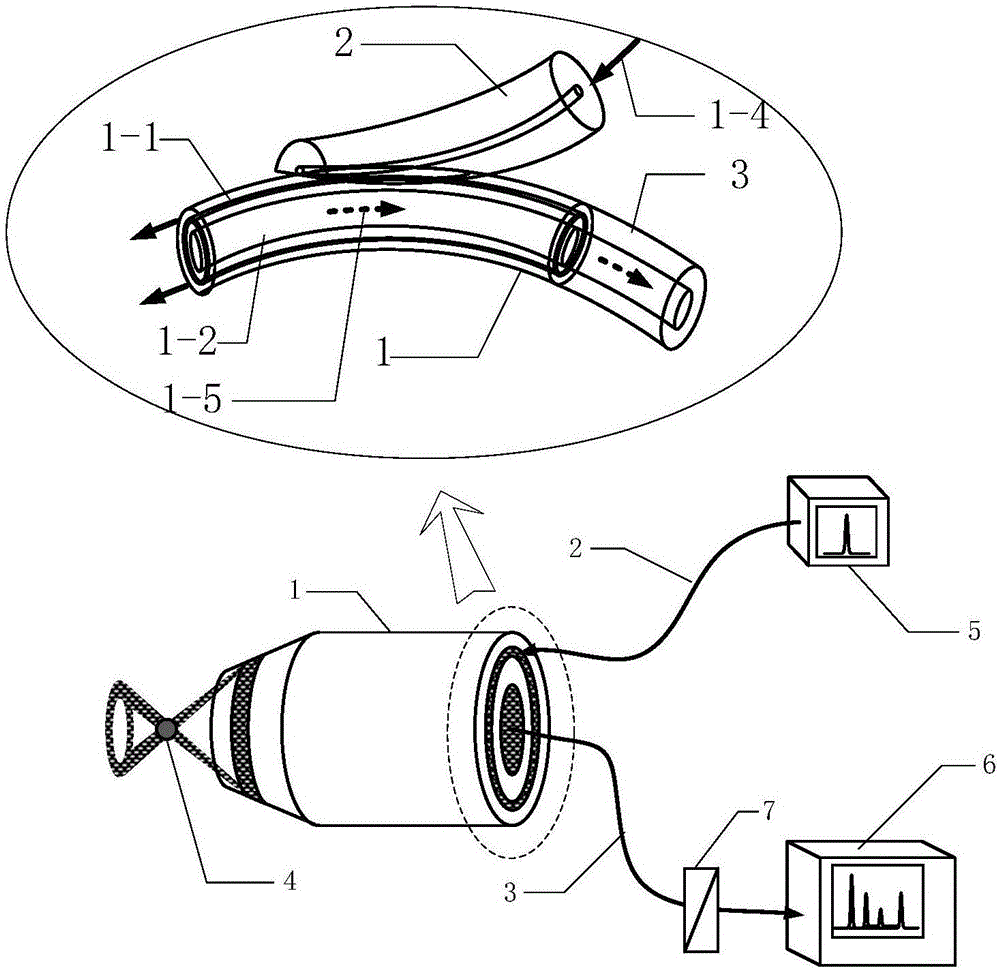

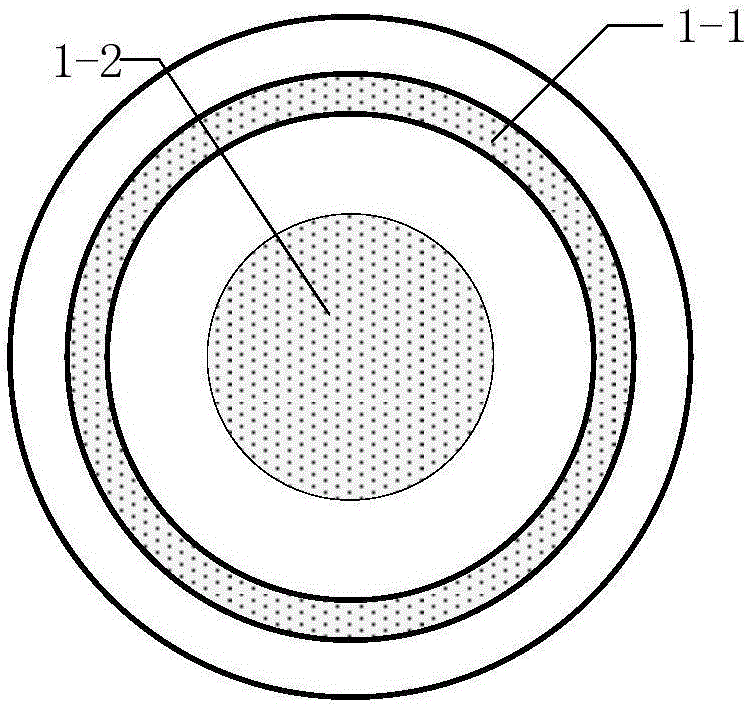

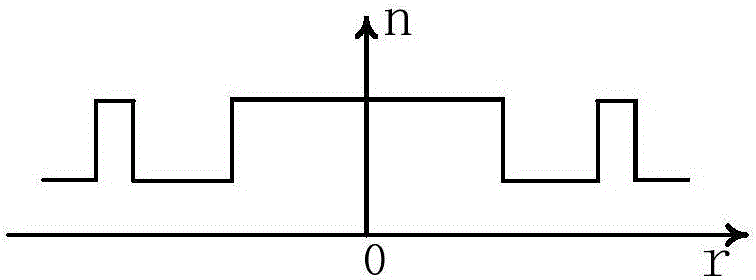

[0042] figure 1 It is a schematic diagram of the optical tweezers fiber Raman probe and its working method. The Raman excitation light output by the laser light source 5 is first transmitted by the ordinary single-mode fiber 2, and the single-mode fiber 2 is coupled with the coaxial dual waveguide channel fiber 1 after side throwing, and then the excitation light can be coupled to the coaxial dual waveguide channel Inside the annular core 1-1 of the optical fiber 1. When the excitation light is transmitted to the fiber end of the probe, the finely ground rotationally symmetrical reflective optical structure 1-3 will converge the excitation light, capture and interact with particles 4 such as microbes or cells to be detected , to generate Raman scattered light, wherein the backscattered light is collected and transmitted by the intermediate core 1-2, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com