Nano platinum-cobalt/porous gold/graphene composite material and preparation method thereof

A composite material and nano-platinum technology, which is applied in the field of nano-materials, can solve the problems of unstable nano-platinum catalyst, high cost of precious metal platinum, and complicated preparation process, so as to shorten the effective contact distance, improve catalytic performance, flexibility and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

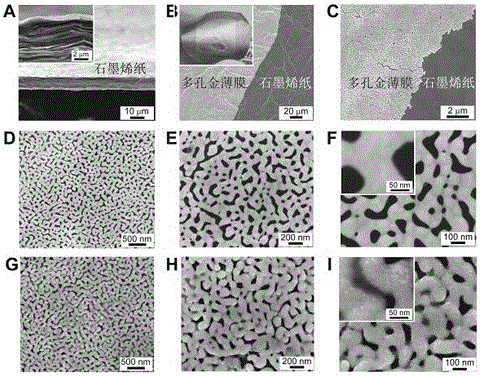

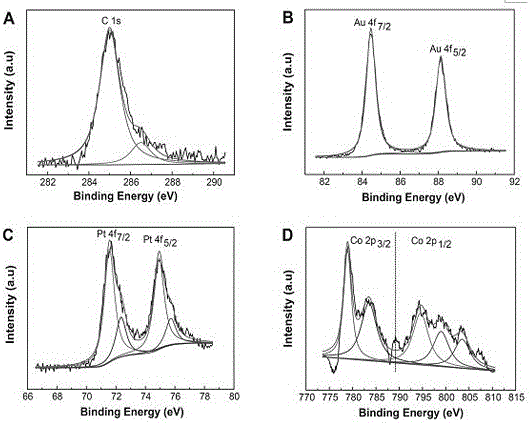

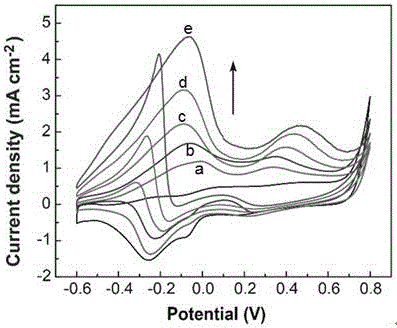

[0056] 1. A nano-platinum-cobalt / porous gold / graphene composite material, consisting of graphene paper loaded with porous gold and platinum-cobalt alloy nanoparticles deposited on its surface, the platinum-cobalt nanoparticles grow in granular form on the porous gold carrier .

[0057] 2. A preparation method of nano-platinum-cobalt / porous gold / graphene composite material, comprising the following steps:

[0058] (1) Prepare graphene oxide with the improved Hummers method, get a certain volume of graphene oxide solution and drop-coat it on a glass sheet to dry naturally, peel it off to get graphene oxide paper, and use the graphene oxide paper obtained with hydroiodic acid (HI ) for 2 hours, washed repeatedly with absolute ethanol and ultrapure water, and dried for later use.

[0059] (2) The Au-Ag alloy leaf was treated with concentrated HNO 3 Corroded for 6 hours, washed 3 times with ultrapure water for later use.

[0060] (3) Lay the washed porous gold on the graphene pape...

Embodiment 2

[0076] 1. A nano-platinum-cobalt / porous gold / graphene composite material, consisting of graphene paper loaded with porous gold and platinum-cobalt alloy nanoparticles deposited on its surface, the platinum-cobalt nanoparticles grow in granular form on the porous gold carrier .

[0077] 2. A preparation method of nano-platinum-cobalt / porous gold / graphene composite material, comprising the following steps:

[0078] (1) Prepare graphene oxide with the improved Hummers method, get a certain volume of graphene oxide solution and drop-coat it on a glass sheet to dry naturally, peel it off to get graphene oxide paper, and use the graphene oxide paper obtained with hydroiodic acid (HI ) for 2 hours, washed repeatedly with absolute ethanol and ultrapure water, and dried for later use.

[0079] (2) The Au-Ag alloy leaf was treated with concentrated HNO 3 Corroded for 6 hours, washed 3 times with ultrapure water for later use.

[0080] (3) Lay the washed porous gold on the graphene pa...

Embodiment 3

[0084] 1. A nano-platinum-cobalt / porous gold / graphene composite material, consisting of graphene paper loaded with porous gold and platinum-cobalt alloy nanoparticles deposited on its surface, the platinum-cobalt nanoparticles grow in granular form on the porous gold carrier .

[0085] 2. A preparation method of nano-platinum-cobalt / porous gold / graphene composite material, comprising the following steps:

[0086] (1) Prepare graphene oxide with the improved Hummers method, get a certain volume of graphene oxide solution and drop-coat it on a glass sheet to dry naturally, peel it off to get graphene oxide paper, and use the graphene oxide paper obtained with hydroiodic acid (HI ) for 2 hours, washed repeatedly with absolute ethanol and ultrapure water, and dried for later use.

[0087] (2) The Au-Ag alloy leaf was treated with concentrated HNO 3 Corroded for 6 hours, washed 3 times with ultrapure water for later use.

[0088] (3) Lay the washed porous gold on the graphene pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com