Manufacturing method of three-dimensional bonding stack interconnect integration for radio-frequency microsystem device

A manufacturing method and micro-system technology, applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve problems such as the inability of precision and volume to meet new requirements, reduce the length of signal lines, and have strong operability , the effect of improving the transmission quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

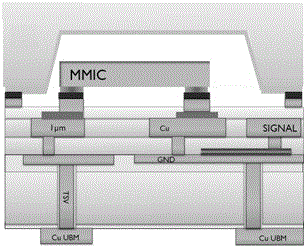

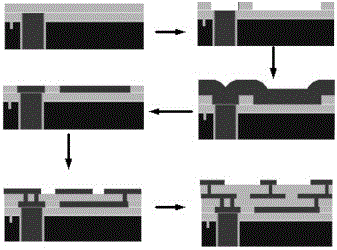

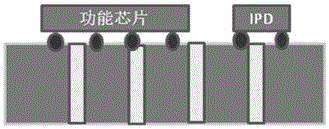

[0022] The integrated manufacturing method for three-dimensional bonded stacked interconnection for radio frequency microsystem devices is characterized in that it includes the following steps:

[0023] 1) Realize the three-dimensional integration of RF microsystem devices through chip-to-wafer bonding, wafer-to-wafer bonding, and multi-layer dielectric-metal alternate wiring, including at least adding three layers of heterogeneous devices to traditional silicon-based planar devices , material or cap;

[0024] 2) High-resistance silicon is used as the substrate or adapter board; the substrate or adapter board is alternately completed with multi-layer dielectric-metal wiring for radio frequency signal transmission and control;

[0025] 3) The heterogeneous compound chip is integrated through chip to wafer bonding;

[0026] 4) All chips are connected to the silicon substrate or the metal bump on the adapter board through the bottom pad to realize signal transmission between dif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com