Method for preparing spinel type lithium manganate coated with metal oxide

A type of lithium manganate and oxide technology, which is applied in the field of preparation of metal oxide-coated spinel-type lithium manganate, can solve the problems that the thickness of the coating layer and the uniformity of the active material have a great influence on the performance, and achieve good results. High temperature electrochemical cycle performance, easy operation, and the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

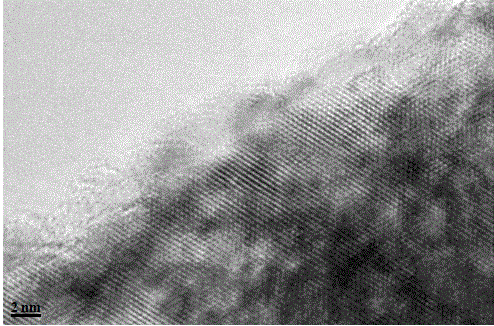

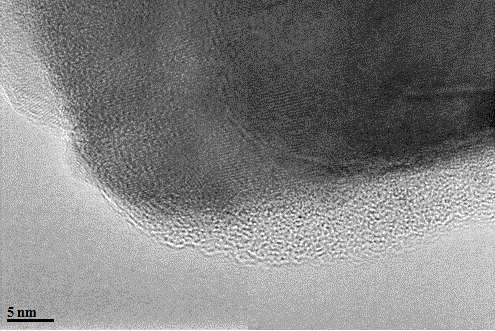

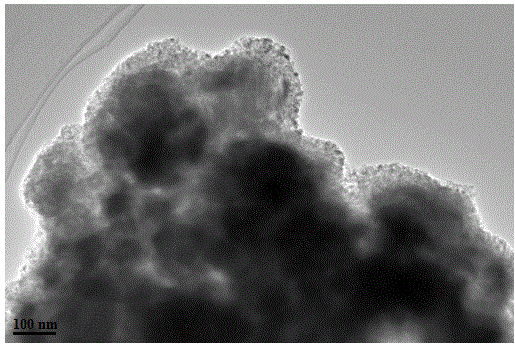

[0028] A preparation method for titanium dioxide-coated spinel lithium manganate, comprising the following steps;

[0029] (1) Add lithium manganate to a certain amount of absolute ethanol, and add 0.2-0.4 mL of concentrated ammonia water, and ultrasonically disperse for 15-30 minutes;

[0030] (2) Measure 1 mL of tetrabutyl titanate, add it to 79 mL of absolute ethanol, and disperse it ultrasonically for 15-30 minutes;

[0031] (3) Pipette 1.7 mL of tetrabutyl titanate solution into the solution in step (1) dropwise with a pipette gun, heat in a water bath at 30-60°C and stir for 6-24 hours;

[0032] (4) Centrifuge the above mixed solution and wash it three times with deionized water and absolute ethanol respectively, then dry at a constant temperature at 80°C for 12 hours, and finally calcinate at 200-500°C for 2-6 hours and cool to room temperature. TiO2-coated spinel lithium manganate was obtained, in which TiO 2 / LiMn 2 o 4 The mass ratio is 1%.

Embodiment 2

[0034] Same as Example 1, the difference is:

[0035] TiO 2 / LiMn 2 o 4 The mass ratio is 5%.

Embodiment 3

[0037] Same as Example 1, the difference is:

[0038] TiO 2 / LiMn 2 o 4 The mass ratio is 20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com