Sulfonated polybenzimidazole cross-linked membrane and preparation method thereof

A technology of sulfonated polybenzimidazole and cross-linking agent, which is applied in the field of functional polymer materials and electrochemistry, can solve the problems of poor mechanical strength and dimensional stability, high price, high fuel permeability, etc., and achieve improved resistance to chemical decomposition, Effect of improving proton conductivity and reducing fuel permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

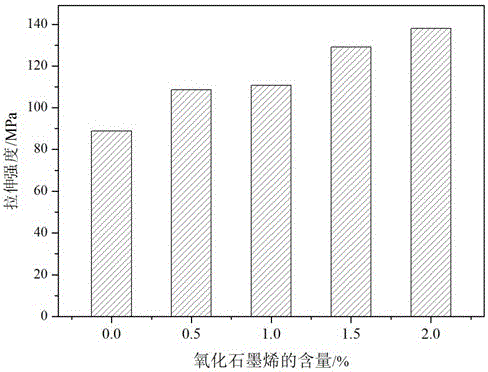

[0029] Cross-linked film SPBI-10-0.5 (the content of amino group is 10%, and the content of graphene oxide is 0.5%)

[0030] (1) Add 150g of polyphosphoric acid into a completely dry three-necked flask, vacuum until there are no bubbles, add 6g of phosphorus pentoxide after heating to 150°C, connect the gas inlet, drying tube, gas outlet, reflux condenser and mechanical stirring In the container, pass inert gas and start stirring until phosphorus pentoxide dissolves. Add 2.1643g 3,3'-diaminobenzidine, 2.4628g 2-sulfonic acid terephthalic acid and 0.1848g 2-aminoterephthalic acid, raise the temperature to 220°C, react for 22 hours, and polycondense at high temperature to obtain amino side chain Sulfonated polybenzimidazole (SPBI-10). Pour it into deionized water while it is hot, and stir while pouring to obtain golden red strips. Filter and wash with water until neutral. Then soak in 10% (mass fraction) NaOH for 24 hours, wash with water until neutral, and dry in an oven at ...

Embodiment 2

[0035] Cross-linked film SPBI-10-2 (the content of amino group is 10%, and the content of graphene oxide is 2.0%)

[0036] (1) Add 150g of polyphosphoric acid into a completely dry three-necked flask, vacuum until there are no bubbles, add 6g of phosphorus pentoxide after heating to 150°C, connect the gas inlet, drying tube, gas outlet, reflux condenser and mechanical stirring In the container, pass inert gas and start stirring until phosphorus pentoxide dissolves. Add 2.1643g 3,3'-diaminobenzidine, 2.4628g 2-sulfonic acid terephthalic acid and 0.1848g 2-aminoterephthalic acid, raise the temperature to 220°C, react for 22 hours, and polycondense at high temperature to obtain amino side chain Sulfonated polybenzimidazole (SPBI-10). Pour it into deionized water while it is hot, and stir while pouring to obtain golden red strips. Filter and wash with water until neutral. Then soak in 10% (mass fraction) NaOH for 24 hours, wash with water until neutral, and dry in an oven at 80...

Embodiment 3

[0041] Cross-linked film SPBI-10-5 (the content of amino group is 10%, and the content of graphene oxide is 5.0%)

[0042] (1) Add 150g of polyphosphoric acid into a completely dry three-necked flask, vacuum until there are no bubbles, add 6g of phosphorus pentoxide after heating to 150°C, connect the gas inlet, drying tube, gas outlet, reflux condenser and mechanical stirring In the container, pass inert gas and start stirring until phosphorus pentoxide dissolves. Add 2.1643g 3,3'-diaminobenzidine, 2.4628g 2-sulfonic acid terephthalic acid and 0.1848g 2-aminoterephthalic acid, raise the temperature to 220°C, react for 22 hours, and polycondense at high temperature to obtain amino side chain Sulfonated polybenzimidazole (SPBI-10). Pour it into deionized water while it is hot, and stir while pouring to obtain golden red strips. Filter and wash with water until neutral. Then soak in 10% (mass fraction) NaOH for 24 hours, wash with water until neutral, and dry in an oven at 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com