Lithium sulfide series solid electrolyte material added with lithium silicon alloy powder and preparation method thereof

A solid electrolyte, lithium-silicon alloy technology, applied in electrolytes, nanotechnology for materials and surface science, circuits, etc., to achieve the effect of high lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

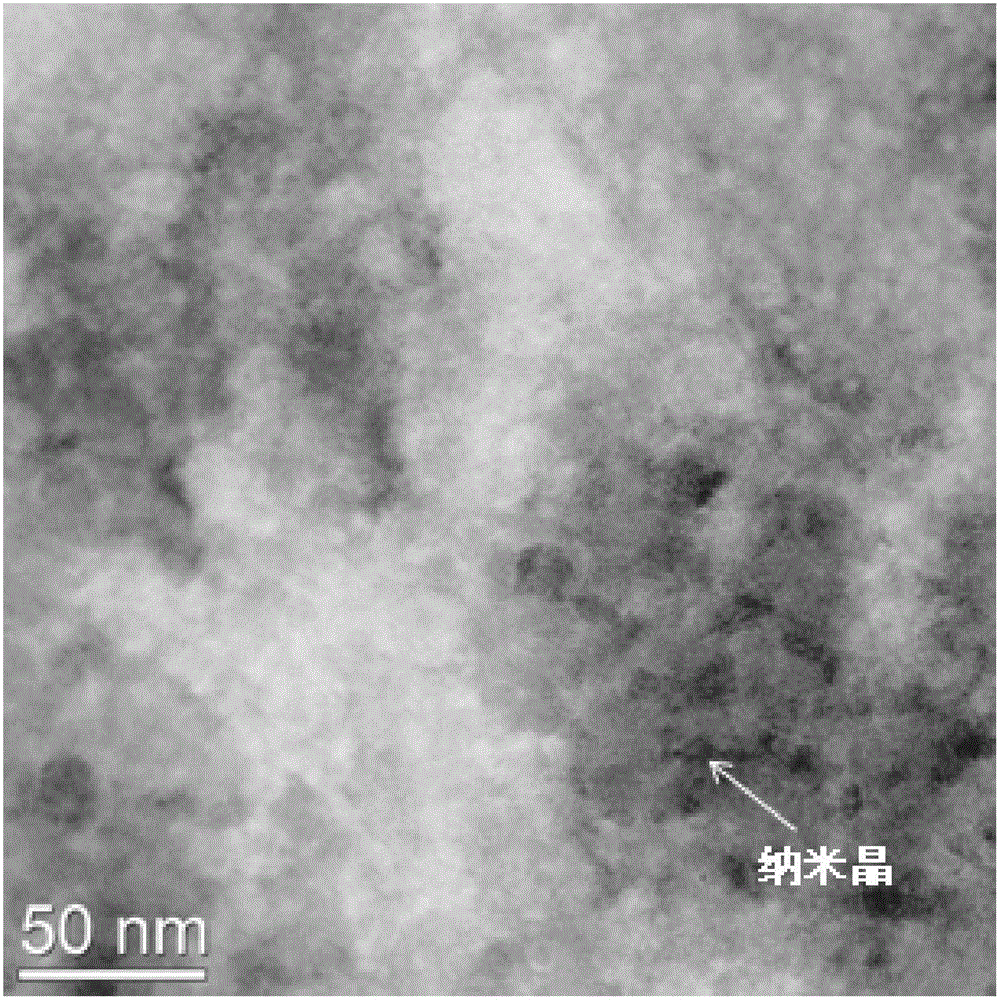

Image

Examples

Embodiment 1

[0023] 1) Mixed high energy ball milling process:

[0024] In a glove box protected by an argon atmosphere with low moisture (≤1ppm) and low oxygen content (≤1ppm), the molar ratio of lithium sulfide, phosphorus sulfide, lithium-silicon alloy powder and sulfur powder is 2.5:0.75:0.05: The proportion of 0.05 ingredients, stirring and mixing, and the zirconia balls with a diameter of 3-10mm are sealed into the ball milling tank. The mass ratio of the zirconia balls in the tank to the mixture is 2:0.7; the sealed ball milling tank Dry mixing ball milling is adopted in a planetary high-energy ball mill, and the ball milling time is 36 hours to obtain an amorphous lithium sulfur phosphorus silicon mixture;

[0025] 2) Heat treatment process:

[0026] The obtained amorphous lithium sulfur phosphorus silicon mixture is sealed in a glove box with low moisture (≤1ppm) and low oxygen content (≤1ppm) protected by an argon atmosphere, and then heated to 100°C under vacuum for heat treatm...

Embodiment 2

[0032] Repeat Example 1, the difference is:

[0033] In step 1), lithium sulfide, phosphorus sulfide, lithium-silicon alloy powder and sulfur powder are mixed in a molar ratio of 3:1:0.1:0.05; the mass ratio of zirconia balls to the mixture is 2:1 , the ball milling time is 30 hours;

[0034] In step 2), the heat treatment is carried out at 180° C., and the heat treatment time is 5 hours.

[0035] After the solid electrolyte powder prepared in this example was pressed into a standard sample, the ion conductivity of the sample in this example was measured at 25°C at room temperature by using the CHI660 electrochemical workstation by AC impedance method to be 6.4×10 -4 S / cm.

Embodiment 3

[0037] Repeat Example 1, the difference is:

[0038] In step 1), lithium sulfide, phosphorus sulfide, lithium-silicon alloy powder and sulfur powder are mixed in a molar ratio of 3:0.5:0.15:0.1; the mass ratio of zirconia balls to the mixture is 2:0.5 , the ball milling time is 40 hours;

[0039] In step 2), the heat treatment is carried out at 220° C., and the heat treatment time is 4 hours.

[0040] After pressing the solid electrolyte powder prepared in this example into a standard sample, the ion conductivity of the sample in this example was measured to be 6.8×10 at a room temperature of 25° C. -4 S / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com