Taste improver for food and drink

A technology for improving agents and food products, which is applied to food ingredients as odor improving agents, food heat treatment, food science and other directions, can solve problems such as flavor reduction, aroma emission and flavor deterioration, and achieve simple and cheap preparation, state improvement, and balance. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

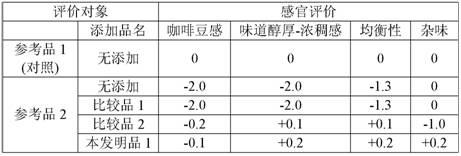

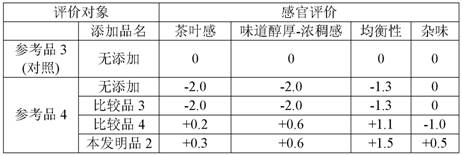

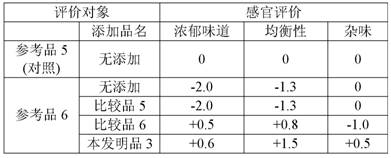

Examples

preparation example Construction

[0079] As a preparation method of cocoa extract, the extraction solvent is mainly water, and vitamin C or sodium ascorbate can be added to the water during extraction or the extract after extraction at about 0.01-5 mass% relative to the raw material of roasted cocoa beans. Antioxidants. In addition, if necessary, a polar organic solvent miscible with water, such as ethanol, glycerin, propylene glycol, and sorbitol, can be mixed and used in an amount in the range of 0.1 to 60% by mass relative to the entire solvent. . The amount of the solvent (water) used for extraction can be arbitrarily selected, and is usually 2-50 times the amount (mass) of the cocoa bean raw material, preferably 5-30 times the amount, more preferably 10-20 times the amount. The temperature and time of extraction can also be arbitrarily determined, and there is no particular limitation. Preferably, the extraction is performed at 10 to 100°C for 30 minutes to 12 hours, especially 1 to 2 hours. As an operat...

Embodiment 1

[0120] (1) Preparation method

[0121] Put 1000 g of roasted and crushed coffee beans (Colombia; L value 22) into 9000 g of water, sterilize at 80°C for 5 minutes, and cool to 45°C. 20g (2% relative to coffee beans) Cellulosin GM5 (registered trademark: galactomannan decomposing enzyme manufactured by HIB Corporation) and 20g (2% relative to coffee beans) Sumizyme (registered trademark: New Japan) Glucoamylase manufactured by Chemical Industry Co., Ltd.), after stirring for 15 minutes, the enzyme treatment was performed at 45°C for 16 hours. After enzymatic treatment, sterilize at 90°C for 10 minutes, then cool to 30°C, use a bleached cloth, and use a basket centrifuge to remove the coffee bean residue solids. Then, use No. 2 filter paper (made by ADVANTEC, reserved A suction filter pre-coated with 150 g of cellulose powder on a particle size of 5 μm, 20 cm, and suction filtration (vacuum 13.33 KPa) under a certain pressure, to obtain 7725 g of a clear extract. This extract was...

Embodiment 2

[0139] (1) Preparation method

[0140] 600 g of green tea (a product obtained by pulverizing the Yabukita variety of Yabukita from Shizuoka Prefecture with a mixer) was put into a solution in which 3.6 g of ascorbic acid was dissolved in 5400 g of soft water, sterilized at 80°C for 5 minutes, and cooled to 40°C. 6 g of tanninase (manufactured by Mitsubishi Chemical Foods Co., Ltd.: 500 U / g) was added thereto, and the mixture was stirred for 15 minutes. Then, 6 g of protease M (manufactured by Amano Enzyme: 5500 U / g) was added, and the enzyme treatment was performed at 40°C for 8 hours. After the enzyme treatment, sterilize at 90°C for 10 minutes, and then cool to 30°C. Use a bleached cloth to remove the solids of tea residues using a basket centrifuge. Then, use No. 2 filter paper (manufactured by ADVANTEC, retain particle size). It is a suction filter pre-coated with 100 g of cellulose powder on 5 μm, 16 cm, and suction filtration is performed under a certain pressure (vacuum d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com