Movable type straw bio-reactor and preparation method thereof

A technology of straw biology and reactor, which is applied in the direction of joint biological treatment, preparation of organic fertilizer, treatment of biological organic parts, etc., can solve the problems of not being able to achieve the best effect, high production input cost, high labor intensity, etc., and meet the requirements of mobile Demand, efficiency improvement, labor saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

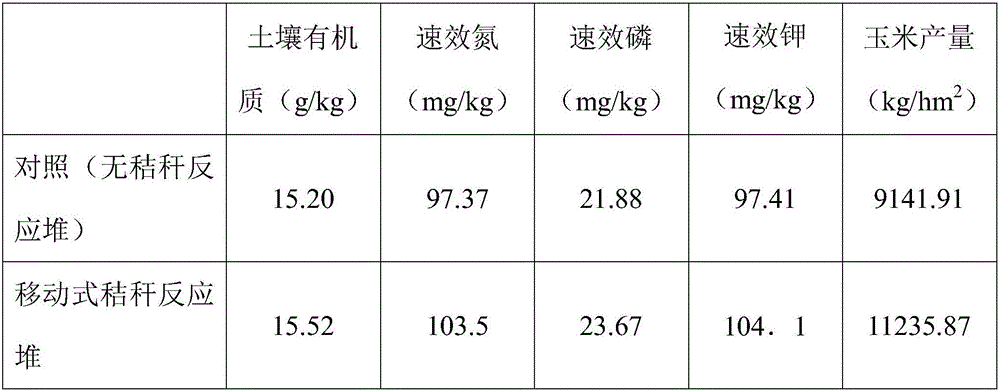

Embodiment 1

[0024] Embodiment 1: The present invention provides a mobile straw bioreactor, including 700 parts of crop straw, 200 parts of livestock and poultry manure, and 1 part of multifunctional bacterial agent; the straw bioreactor is made into a regular block structure of any shape and size , can be pressed and produced according to the planting environment and customer requirements. By using molds of different shapes and sizes, products of corresponding specifications can be produced. The mixed material is pressed into a cube, cylinder, cuboid, cone, sphere, truncated cone, truncated prism, or rhombus by using a hydraulic briquetting machine (with a heightened feed inlet). Farmers can apply the product at an appropriate location according to their needs to meet the needs of mobility, which is convenient and fast.

[0025] Among them, the multifunctional bacterial agent is a self-developed product in powder form. Its raw material components include cellulolytic bacteria, hemicellul...

Embodiment 2

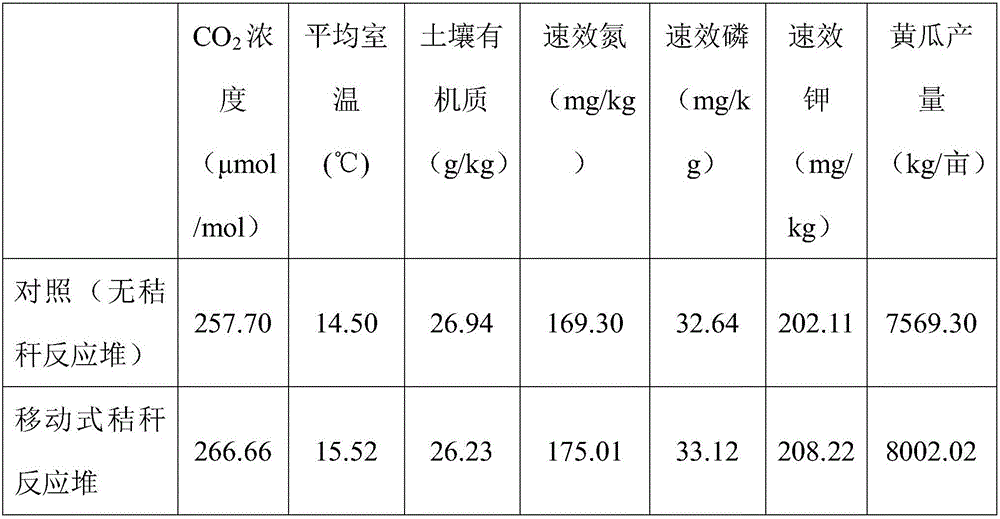

[0040] Embodiment 2: The present invention provides a mobile straw bioreactor, including 750 parts of crop straw, 250 parts of livestock and poultry manure, and 2 parts of multifunctional bacterial agent; the straw bioreactor is made into a regular block structure of any shape and size , can be pressed and produced according to the planting environment and customer requirements. By using molds of different shapes and sizes, products of corresponding specifications can be produced. The mixed material is pressed into a cube, cylinder, cuboid, cone, sphere, truncated cone, truncated prism, or rhombus by using a hydraulic briquetting machine (with a heightened feed inlet). Farmers can apply the product at an appropriate location according to their needs to meet the needs of mobility, which is convenient and fast.

[0041] Among them, the multifunctional bacterial agent is a self-developed product in powder form. Its raw material components include cellulolytic bacteria, hemicellu...

Embodiment 3

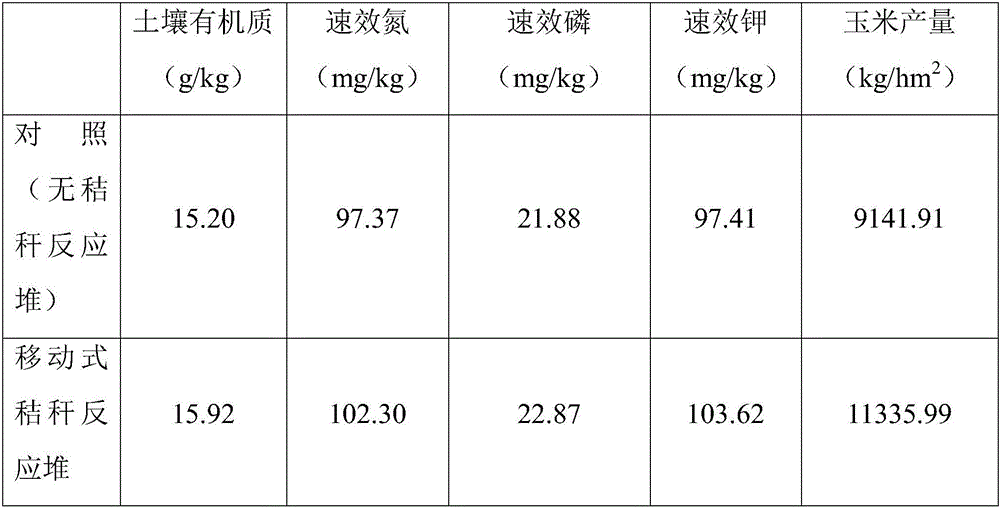

[0057] Embodiment 3: The present invention provides a mobile straw bioreactor, including 800 parts of crop straw, 300 parts of livestock and poultry manure, and 3 parts of multifunctional bacterial agent; the straw bioreactor is made into a regular block structure of any shape and size , can be pressed and produced according to the planting environment and customer requirements. By using molds of different shapes and sizes, products of corresponding specifications can be produced. The mixed material is pressed into a cube, cylinder, cuboid, cone, sphere, truncated cone, truncated prism, or rhombus by using a hydraulic briquetting machine (with a heightened feed inlet). Farmers can apply the product at an appropriate location according to their needs to meet the needs of mobility, which is convenient and fast.

[0058] Among them, the multifunctional bacterial agent is a self-developed product in powder form, and its raw material components include cellulolytic bacteria, hemic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com