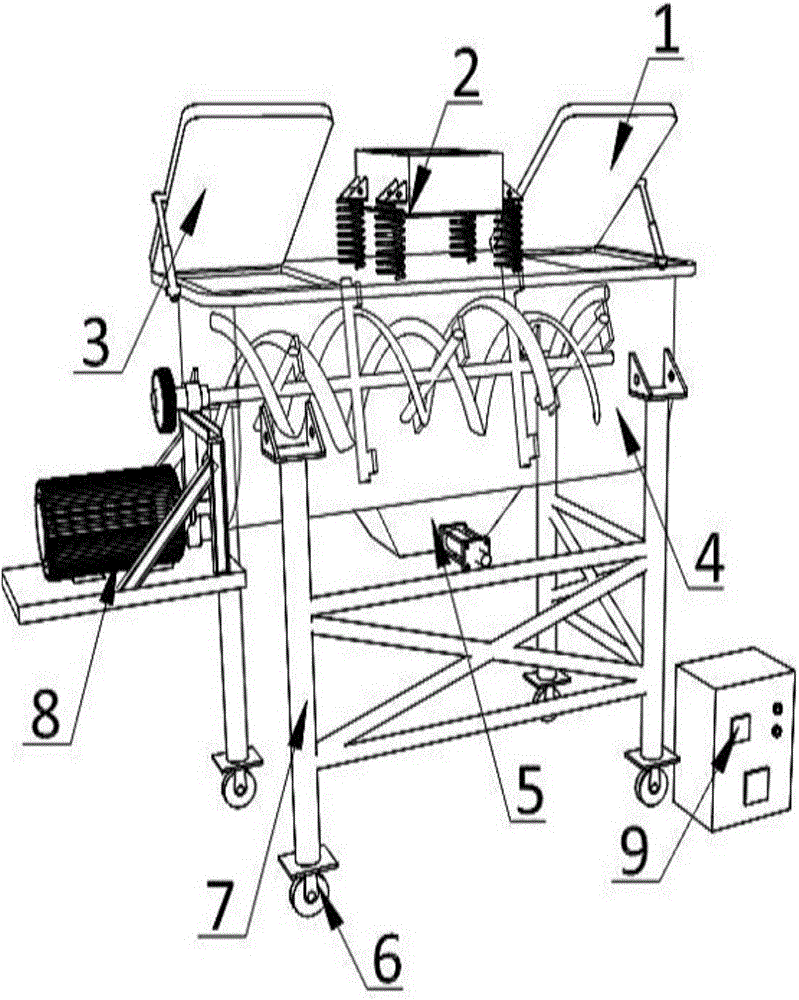

Heavy metal contaminated soil treatment agent stirring equipment and operating method thereof

A technology for contaminated soil and chemical treatment, applied in the restoration of contaminated soil, mixer accessories, chemical instruments and methods, etc., can solve problems such as difficult maintenance, low processing efficiency, poor flexibility and convenience, and achieve high automation system and structure Simple, transportable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

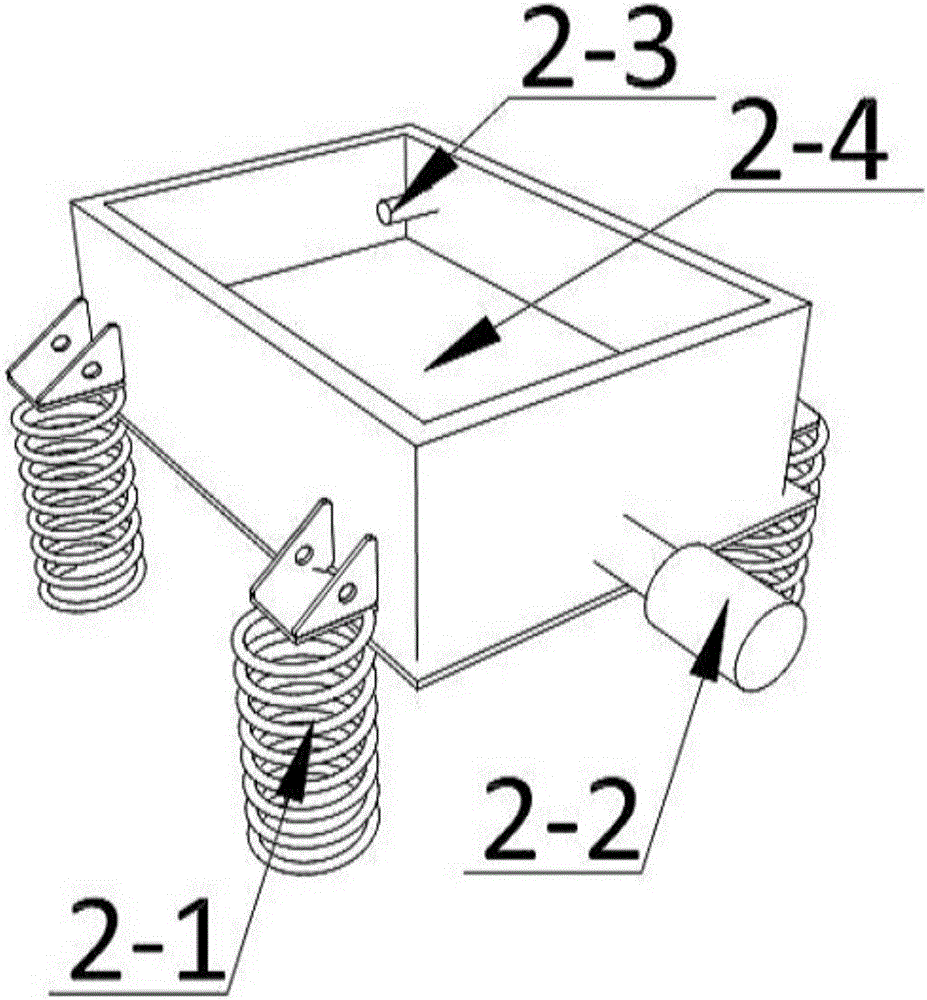

Method used

Image

Examples

Embodiment 1

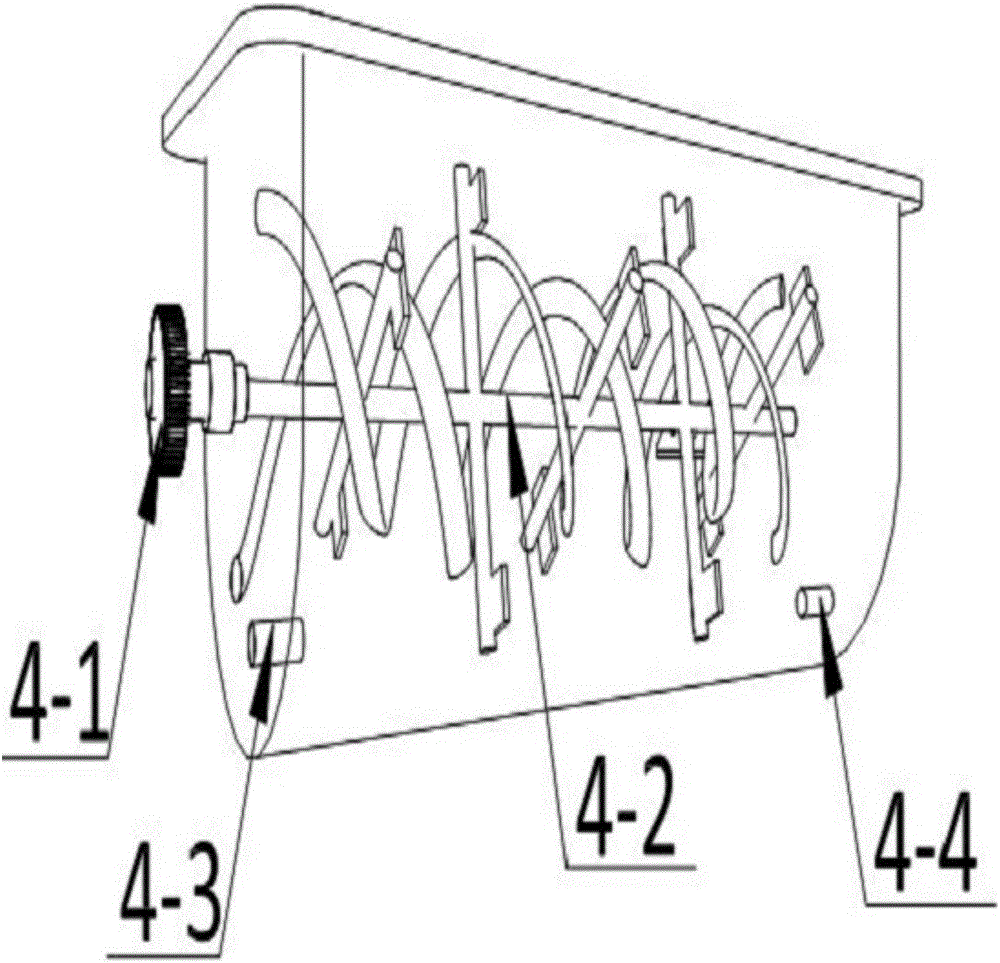

[0055] Propeller blade 4-2-2 of the present invention is manufactured according to the following steps, and in parts by weight:

[0056] Step 1: Add 1370 parts of ultrapure water with a conductivity of 2.20μS / cm into the reactor, start the stirrer in the reactor at a speed of 60rpm, start the heating pump, and raise the temperature in the reactor to 40°C; add in order 60 parts of methyl 3-[5-[methyl(methylsulfonyl)amino]-1-pentyn-1-yl]benzoate, 4-[4,5-dihydro-3-methyl-4- 50 parts of [[4-methyl-3-[[(4-methylphenyl)amino]sulfonyl]phenyl]azo]-5-oxo-1H-pyrazol-1-yl]benzenesulfonic acid, Bis[3-[4,5-dihydro-4-[(2-hydroxy-5-methyl-3-nitrobenzene)azo-3-methyl-5-oxo-1H-1-pyrazole Base]] benzenesulfonamide (2-)] 90 parts of chromic acid (1-) sodium, stir until completely dissolved, adjust the pH value to 3.0, adjust the stirrer speed to 130rpm, the temperature is 90 ° C, and the esterification reaction is carried out for 10 Hour;

[0057] Step 2: Take 10 parts of sodium chromate bis[...

Embodiment 2

[0062] Propeller blade 4-2-2 of the present invention is manufactured according to the following steps, and in parts by weight:

[0063] Step 1: Add 1640 parts of ultrapure water with a conductivity of 4.20μS / cm into the reactor, start the stirrer in the reactor at a speed of 120rpm, start the heating pump, and raise the temperature in the reactor to 70°C; add in order 120 parts of methyl 3-[5-[methyl(methylsulfonyl)amino]-1-pentyn-1-yl]benzoate, 4-[4,5-dihydro-3-methyl-4- 150 parts of [[4-methyl-3-[[(4-methylphenyl)amino]sulfonyl]phenyl]azo]-5-oxo-1H-pyrazol-1-yl]benzenesulfonic acid, Bis[3-[4,5-dihydro-4-[(2-hydroxy-5-methyl-3-nitrobenzene)azo-3-methyl-5-oxo-1H-1-pyrazole Base]] benzenesulfonamide (2-)] sodium chromate (1-) 200 parts, stir until completely dissolved, adjust the pH value to 6.0, adjust the stirrer speed to 250rpm, the temperature is 130 ° C, the esterification reaction is 20 Hour;

[0064] Step 2: Take 50 parts of sodium chromate bis[2-(4,5-dihydro-3-methy...

Embodiment 3

[0069] Propeller blade 4-2-2 of the present invention is manufactured according to the following steps, and in parts by weight:

[0070] Step 1: Add 1440 parts of ultrapure water with a conductivity of 3.20μS / cm into the reactor, start the stirrer in the reactor at a speed of 90rpm, start the heating pump, and raise the temperature in the reactor to 60°C; add in order 80 parts of methyl 3-[5-[methyl(methylsulfonyl)amino]-1-pentyn-1-yl]benzoate, 4-[4,5-dihydro-3-methyl-4- 100 parts of [[4-methyl-3-[[(4-methylphenyl)amino]sulfonyl]phenyl]azo]-5-oxo-1H-pyrazol-1-yl]benzenesulfonic acid, Bis[3-[4,5-dihydro-4-[(2-hydroxy-5-methyl-3-nitrobenzene)azo-3-methyl-5-oxo-1H-1-pyrazole Base]] benzenesulfonamide (2-)] sodium chromate (1-) 180 parts, stir until completely dissolved, adjust the pH value to 4.0, adjust the speed of the agitator to 190rpm, the temperature is 110 ° C, and the esterification reaction takes 15 Hour;

[0071] Step 2: Take 30 parts of sodium chromate bis[2-(4,5-di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com