Preparing method for large-area metal nanometer needle-tip array on flexible substrate

A large-area metal and flexible substrate technology, applied in the field of nanotechnology, to achieve good performance, expand the application range, and reduce the cost of preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

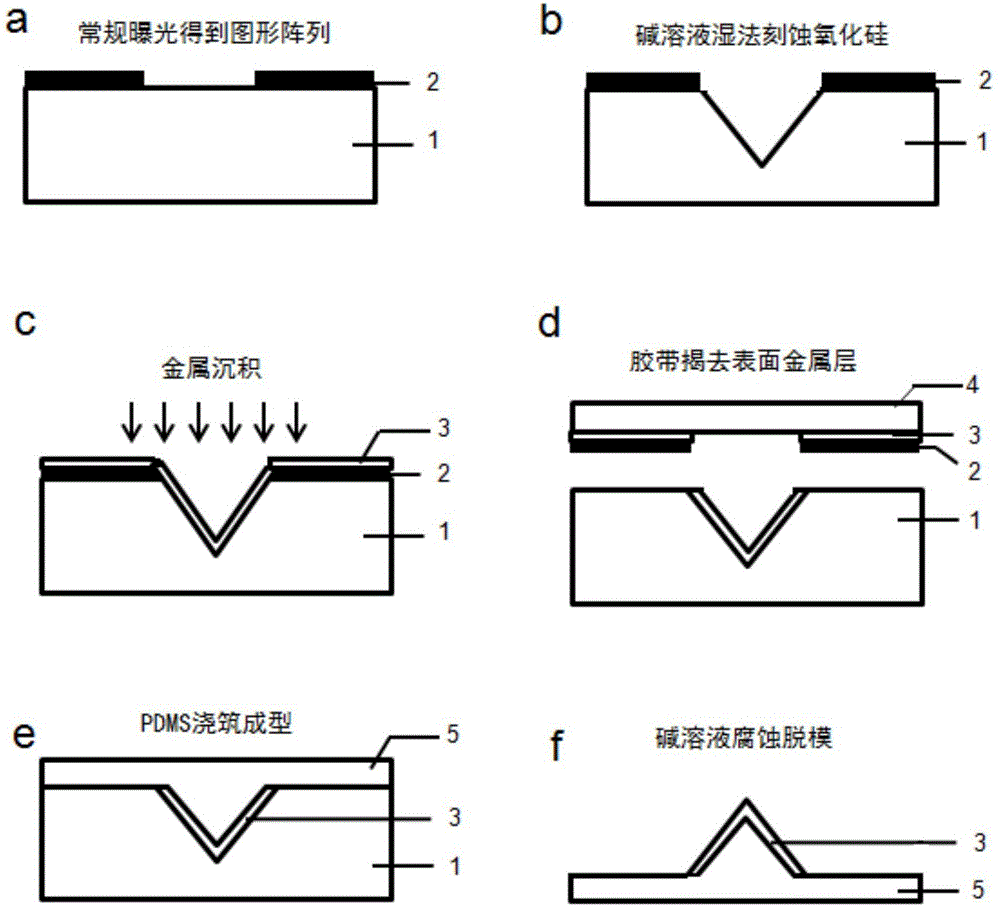

[0029] A method for preparing a large-area metal nano-tip array on a flexible substrate in this embodiment, such as figure 1 shown, including the following steps:

[0030] (1) On a clean silicon wafer substrate 1, a metallic chromium thin film is vapor-deposited, and the silicon wafer substrate 1 (the crystal direction of the silicon wafer is ) deposited with a 50 nanometer thick chromium thin film is cut into 1 cm × 1 cm. Sonicate the small piece with acetone, absolute ethanol, and deionized water for five minutes respectively, and dry it with high-purity nitrogen for later use; mark the above-mentioned single silicon wafer as sample i, and then spin-coat PMMA (polymethyl methacrylate) on sample i ) in chloroform solution (the weight-average molecular weight is 950K, and the mass percentage concentration of the photoresist is 6%), the spin coating speed is 4000rmp, and finally the glue is baked at 180°C for 4 minutes on a hot stage to obtain a photoresist with a thickness of ...

Embodiment 2

[0037] The technical solution of this embodiment is basically the same as that of Embodiment 1, except that the flexible soft mold material poured in step (6) is PVA (polyvinyl alcohol).

Embodiment 3

[0039] The technical solution of this embodiment is basically the same as that of Embodiment 1, except that the flexible soft mold material poured in step (6) is PMMA (polymethyl methacrylate).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com