Method for preparing biomass activated carbon through vacuum freeze drying

A vacuum freeze-drying and biomass technology, applied in chemical instruments and methods, carbon compounds, inorganic chemistry, etc., can solve problems such as weak synergistic adsorption capacity, increase in specific surface area, environmental pollution, etc., to protect the environment, reduce pollution, enrich The effect of the porous structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

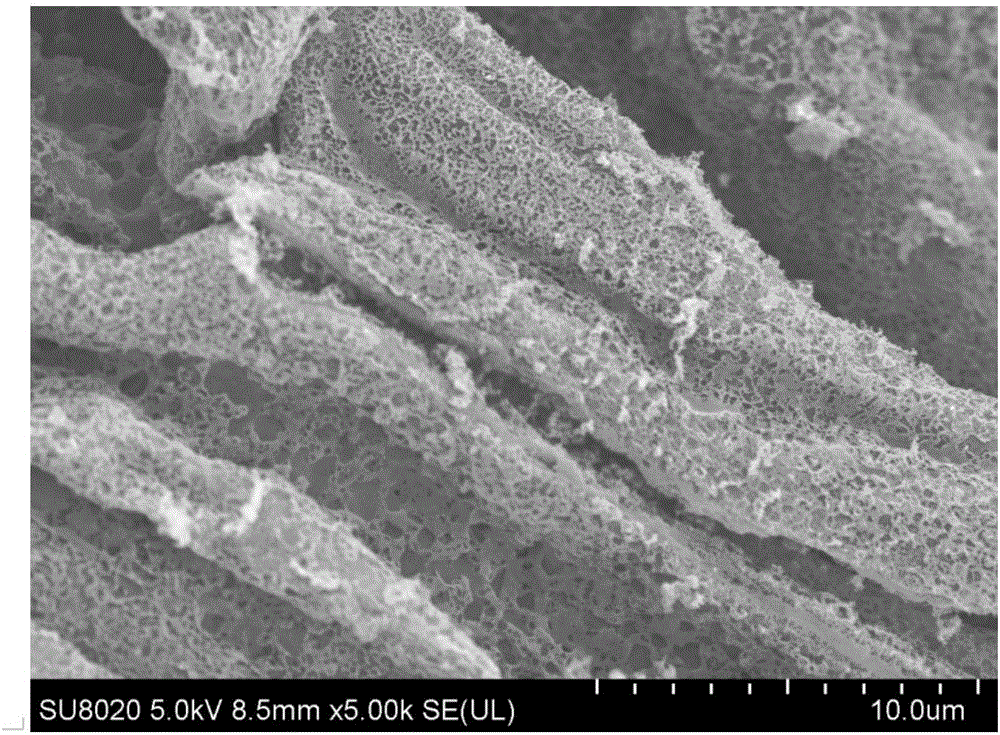

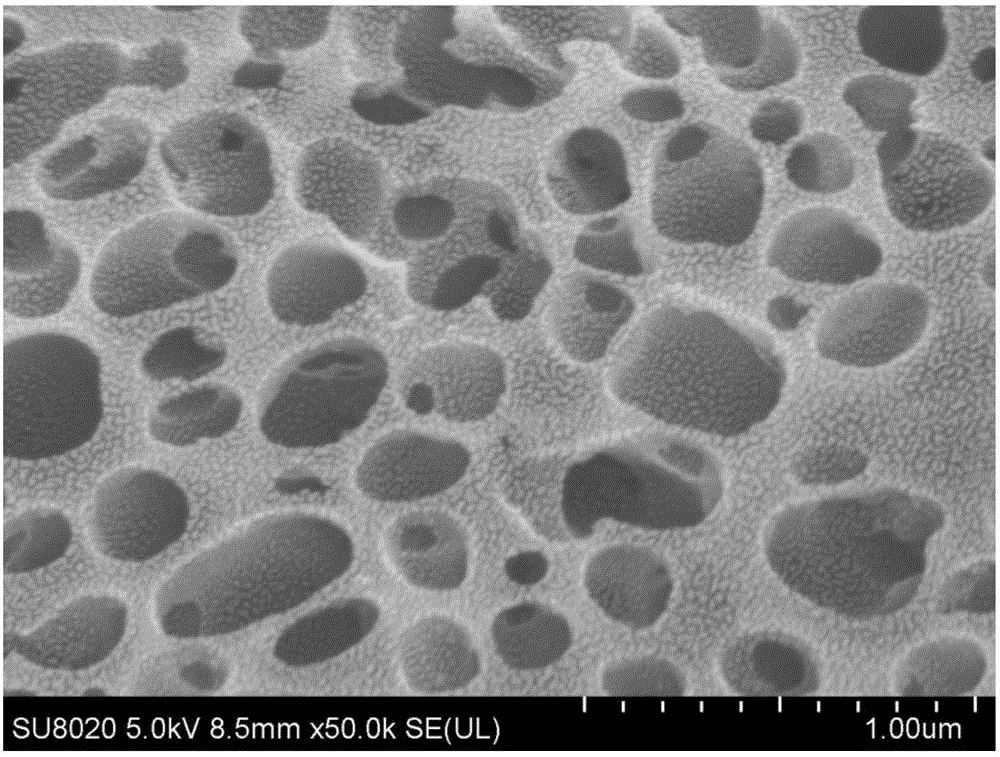

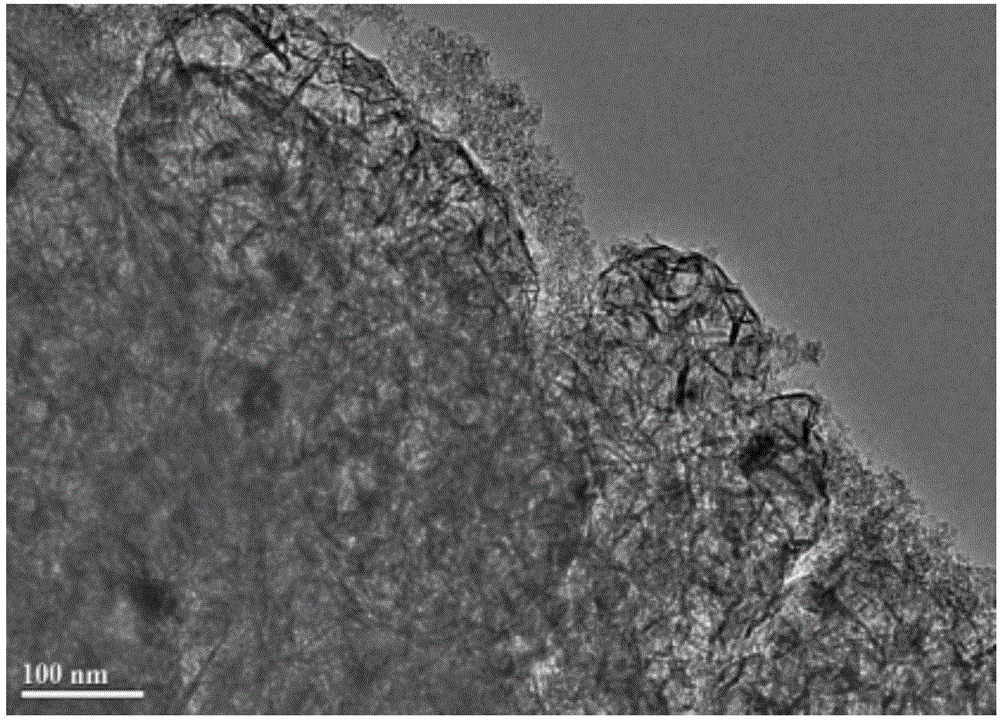

[0029] Physical pretreatment of moso bamboo: first take moso bamboo and place it in an oven at 100 degrees Celsius to dry for 24 hours, then crush it and pass it through an 80-mesh sieve for use. Tartaric acid hydrothermal treatment of moso bamboo: Take 5g of pulverized samples and place them in a 100ml polyethylene hydrothermal kettle liner, add 60ml of tartaric acid solution with a mass fraction of 10%, seal the reaction kettle after ultrasonication for 20-40 minutes, put Heat in an oven at 80°C for 2 hours. After the sample is cooled to room temperature, centrifuge and wash with distilled water until neutral to obtain a black intermediate product. Activator soaking and vacuum freeze-drying: Take 2g of the above-mentioned black sample and put it in a clean beaker, first add 3g of potassium hydroxide, sodium hydroxide or both, then add 20ml of deionized water, put it into a magnetic bar and stir After dispersing for 2-3 hours, the dispersion liquid is frozen with liquid nitro...

example 2

[0032] Physical pretreatment of moso bamboo: first take moso bamboo and place it in an oven at 100 degrees Celsius to dry for 24 hours, then crush it and pass it through an 80-mesh sieve for use. Tartaric acid hydrothermal treatment of moso bamboo: Take 5g of pulverized samples and place them in a 100ml polyethylene hydrothermal kettle liner, add 60ml of tartaric acid solution with a mass fraction of 10%, seal the reaction kettle after ultrasonication for 20-40 minutes, put Heat it in an oven at 100 degrees Celsius for 2 hours. After the sample is cooled to room temperature, centrifuge and wash with distilled water until neutral to obtain a black intermediate product. Activator soaking and vacuum freeze-drying: Take 2g of the above-mentioned black sample and put it in a clean beaker, first add 3g of potassium hydroxide, sodium hydroxide or both, then add 20ml of deionized water, put it into a magnetic bar and stir After dispersing for 2-3 hours, the dispersion liquid is frozen...

example 3

[0034] Physical pretreatment of moso bamboo: first take moso bamboo and place it in an oven at 100 degrees Celsius to dry for 24 hours, then crush it and pass it through an 80-mesh sieve for use. Tartaric acid hydrothermal treatment of moso bamboo: Take 5g of pulverized samples and place them in a 100ml polyethylene hydrothermal kettle liner, add 60ml of tartaric acid solution with a mass fraction of 10%, seal the reaction kettle after ultrasonication for 20-40 minutes, put Heat in an oven at 120°C for 2 hours. After the sample is cooled to room temperature, centrifuge and wash with distilled water until neutral to obtain a black intermediate product. Activator soaking and vacuum freeze-drying: Take 2g of the above-mentioned black sample and put it in a clean beaker, first add 3g of potassium hydroxide, sodium hydroxide or both, then add 20ml of deionized water, put it into a magnetic bar and stir After dispersing for 2-3 hours, the dispersion liquid is frozen with liquid nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com