High-frequency low-loss manganese zinc ferrite and manufacture method thereof

A technology of manganese zinc ferrite and its manufacturing method, which is applied in the direction of magnetic objects, magnetic materials, electrical components, etc., can solve the problems of increasing the resistance of domain wall movement, etc., and achieve less pores, fine and uniform grain structure, and high frequency Effect of Loss Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

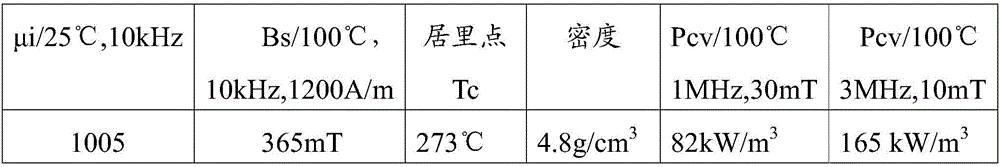

Embodiment 1

[0030] Use Fe in the main material 2 o 3(Bao Steel Red) 54mol%, ZnO (Jinghua Zinc) 6mol%, MnO (Hunan Jinrui Manganese, converted to Mn 3 o 4 ) 40mol%, mixing time in a ball mill for 30 minutes, holding time in a sintering furnace at 900°C for 2 hours; adding auxiliary material dispersant 0.5wt%, defoamer 1wt% and polyvinyl alcohol binder 2wt% after secondary ball milling The time is 1 hour to make powder; add trace additive 50ppm SiO 2 、3000ppm CaCO 3 , 150ppm Nb 2 o 5 , 1000ppm TiO 2 、350ppm V 2 o 5 , 150ppm ZrO 2 , 80ppm HfO 2 , spray granulation, use a press to press the granulated powder into a blank and put it in a microwave atmosphere sintering furnace for secondary sintering to obtain a high-frequency and low-power manganese-zinc ferrite material. Among them, the secondary sintered The sintering temperature is 1150°C, and the sintering is held at 3% oxygen partial pressure for 1 hour. When the temperature is lowered, the cooling temperature and oxygen partial...

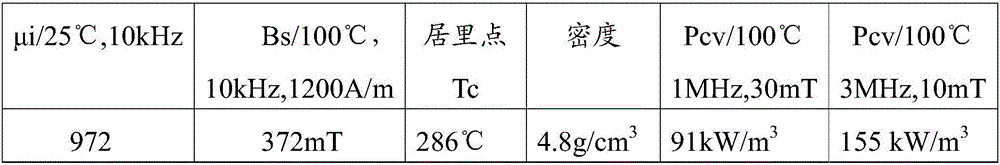

Embodiment 2

[0034] The main material uses Fe 2 o 3 (Bao Steel Red) 56mol%, ZnO (Jinghua Zinc) 5mol%, MnO (Hunan Jinrui Manganese, converted to Mn 3 o 4 ) 39mol%, mixing time in a ball mill for 30 minutes, holding time in a sintering furnace at 910°C for 2 hours; adding auxiliary materials dispersant 0.5wt%, defoamer 1wt% and polyvinyl alcohol binder 2wt% after secondary ball milling The time is 1 hour to make powder; add trace additive 50ppm SiO 2 , 2500ppm CaCO 3 , 150ppm Nb 2 o 5 , 500ppm TiO 2 、300ppm V 2 o 5 , 150ppm ZrO 2 , 100ppm Ta 2 o 5 , spray granulation, use a press to press the granulated powder into a blank and put it in a microwave atmosphere sintering furnace for secondary sintering to obtain a high-frequency and low-power manganese-zinc ferrite material. Among them, the secondary sintered The sintering temperature is 1160°C, and the sintering is held at 3% oxygen partial pressure for 1 hour. When the temperature is lowered, the cooling temperature and oxygen pa...

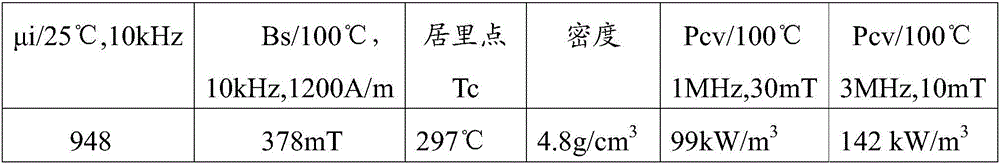

Embodiment 3

[0038] The main material uses Fe 2 o 3 (Bao Steel Red) 57mol%, ZnO (Jinghua Zinc) 6mol%, MnO (Hunan Jinrui Manganese, converted to Mn 3 o 4 ) 37mol%, mixed in a ball mill for 30 minutes, held in a sintering furnace at 920°C for 2 hours; added auxiliary materials dispersant 0.5wt%, defoamer 1wt% and polyvinyl alcohol binder 2wt% after secondary ball milling The time is 1 hour to make powder; add trace additive 50ppm SiO 2 、2000ppm CaCO 3 , 250ppm Nb 2 o 5 , 500ppm TiO 2 、300ppm V 2 o 5 , 200ppm ZrO 2 , 120ppm Ta 2 o 5 , spray granulation, use a press to press the granulated powder into a blank and put it in a microwave atmosphere sintering furnace for secondary sintering to obtain a high-frequency and low-power manganese-zinc ferrite material. Among them, the secondary sintered The sintering temperature is 1170°C, and the sintering temperature is kept at 3% oxygen partial pressure for 1 hour. When the temperature is lowered, the cooling temperature and oxygen partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com