Preparation method of continuous silicon carbide ceramic fiber thermistor

A technology of silicon carbide ceramics and silicon carbide fibers, which is applied in the field of continuous silicon carbide ceramic fiber thermistor preparation to achieve fast temperature response and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following embodiments will further describe the present invention in detail in conjunction with the accompanying drawings.

[0036] (1) Using the Yajima route, using dimethyldichlorosilane as a raw material, using sodium metal as a reducing agent, and using toluene or xylene as a solvent, dechlorination at 110 ° C to obtain polydimethylsilane; then, polydimethylsilane Carbosilane is pyrolyzed at 450°C under an inert atmosphere, and the molecular structure is rearranged to prepare polycarbosilane. The number average molecular weight measured by gel permeation chromatography (GPC) is Mn=995, and the melting point measured by the melting point instrument is 181°C .

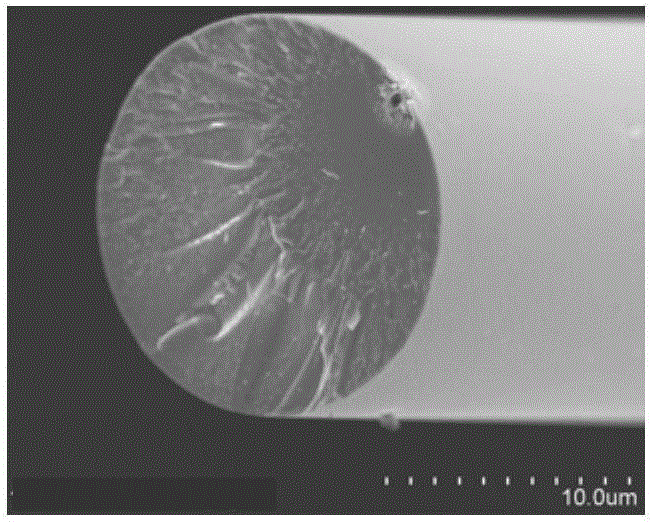

[0037] (2) Put polycarbosilane into a spinning vessel, heat to 275° C. under the protection of nitrogen to melt the precursor, and then stand still for degassing for 4 hours. Extrude with a φ0.3mm spinneret and wind at a speed of 170m / s to obtain a precursor fiber with a diameter of 18μm, also known as a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com