Potassium-type farmland passivation agent based on raw materials of molybdenum ore tailings and preparation method and application of passivation agent

The technology of passivating agent and tailing sand is applied in the field of farmland passivating agent, which can solve the problems of environmental pollution risk, occupation of land, waste of resources, etc., and achieve the effects of simple preparation process, strong applicability and quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The preparation steps of passivating agent are as follows:

[0045] (1) Take 15g of molybdenum ore tailings and grind through a 200 mesh sieve, add 30mL, 1mol / L H 2 SO 4 Vibrate in a shaker, filter and separate, dry, and then divide into crucibles, add an equal mass of NaOH to each crucible, heat it in a muffle furnace at 823K for 3 hours, take it out to cool naturally, and grind it for use.

[0046] (2) Take 5g of the product that is ground for use in step (1) and add 90mL of water to dissolve it, centrifugally filter the supernatant, transfer it to a teflon tank, add 5.4g of sodium metaaluminate, 15.75g of water glass, and dissolve it at 343K Stir for 1h;

[0047] (3) Transfer the stirred product in the teflon tank to the reactor, react at 373K for 15 hours, then cool the resulting reaction product to room temperature, filter, wash, and dry, and the obtained powder solid is the farmland passivation agent.

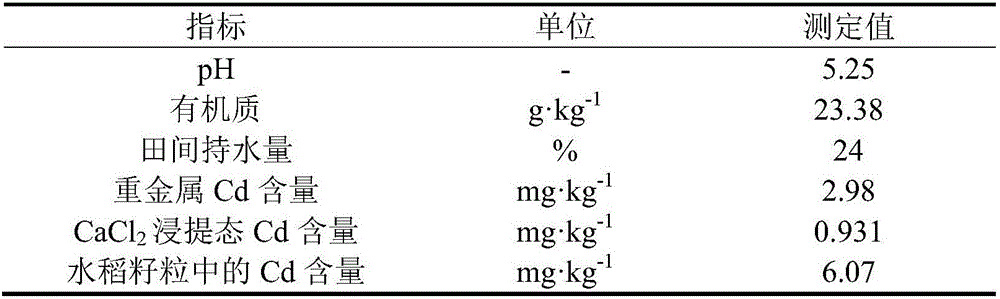

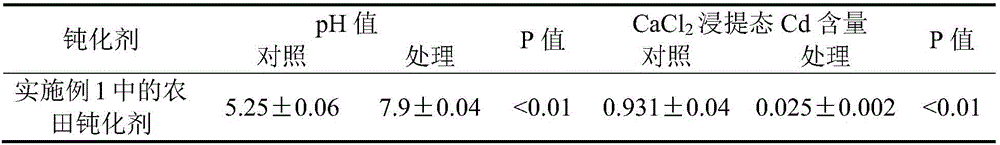

[0048]The prepared farmland passivation agent was used for...

Embodiment 2

[0056] The preparation steps of passivating agent are as follows:

[0057] (1) Take 15g of molybdenum ore tailings and grind through a 200 mesh sieve, add 30mL, 1mol / L H 2 SO 4 Vibrate in a shaker, filter and separate, dry, and then divide into crucibles, add NaOH to each crucible, heat in a muffle furnace at 873K for 2 hours, take it out to cool naturally, grind it for use, and add NaOH to each crucible The quality of NaOH is that the mass ratio of molybdenum ore tailings to NaOH after drying is 0.85.

[0058] (2) Get 5g of the product that is ground for use in step (1) and add 90mL of water to dissolve it, and get the supernatant by centrifugal filtration, transfer it to a teflon tank, add 5.4g of sodium metaaluminate, 15.75g of water glass, and dissolve it at 333K Stir for 3h;

[0059] (3) Transfer the stirred product in the teflon tank to the reactor, react at 373K for 12 hours, then cool the resulting reaction product to room temperature, filter, wash, and dry, and the...

Embodiment 3

[0068] The preparation steps of passivating agent are as follows:

[0069] (1) Take 15g of molybdenum ore tailings and grind through a 200 mesh sieve, add 30mL, 1mol / L H 2 SO 4 Vibrate in a shaker, filter and separate, dry, and then divide into crucibles, add an equal mass of NaOH to each crucible, heat it in a muffle furnace at 823K for 3 hours, take it out to cool naturally, and grind it for use.

[0070] (2) Get 5g of the product that is ground for use in step (1) and add 90mL of water to dissolve it, and get the supernatant by centrifugal filtration, transfer it to a teflon tank, add 5.4g of sodium metaaluminate, 15.75g of water glass, and dissolve it at 343K Stir for 2h;

[0071] (3) Transfer the stirred product in the teflon tank to the reactor, react at 403K for 8 hours, then cool the obtained reaction product to room temperature, filter, wash, and dry, and the obtained powder solid is the farmland passivation agent.

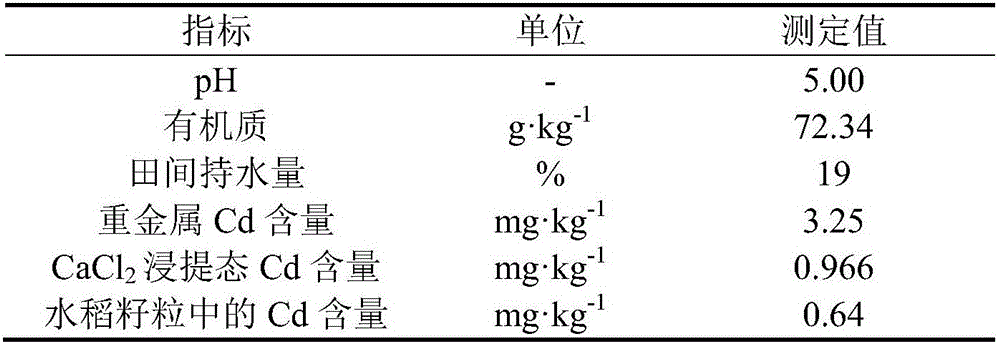

[0072] The prepared farmland passivation agent w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com