Titanium alloy pipe for petroleum and natural gas conveying and preparation method thereof

A technology of titanium alloy pipe and alloy ingot, which is applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of easy corrosion of pipeline steel pipes, blockage of oil pipelines, etc., and achieve the effect of solving wax deposition, prolonging service life and reducing losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

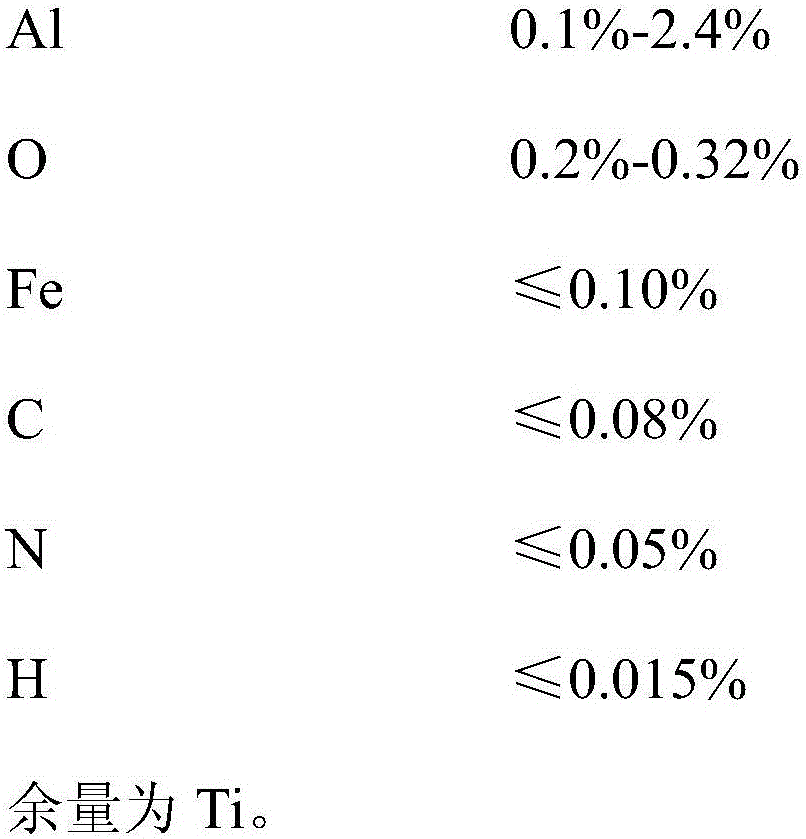

[0071] Dosing according to the following components:

[0072] Al 0.1%; O 0.2%; the balance is Ti.

[0073] The specific preparation method is:

[0074]After batching, it is smelted in a vacuum consumable electrode electric arc furnace, and is cooled by cooling circulating water while melting to obtain an alloy ingot; the alloy ingot is forged into a rod, and then machined into a φ630mm smooth rod, and then its polished rod Put it into an electric heating furnace for heating, raise the temperature to 980°C, and keep it warm for 355 minutes. After the bar is out of the furnace, it is pierced with a cross-rolling piercer at a piercing speed of 15mm per second; into the soaking furnace and heated at 860°C for 15 minutes; after coming out of the furnace, it enters the hot rolling pipe mill with a rolling speed of 33mm / s; Outer diameter, the sizing rolling speed is 60mm per second, after sizing, it is sent to the heating furnace for annealing, kept at 720°C for 120min, and cooled ...

Embodiment 2

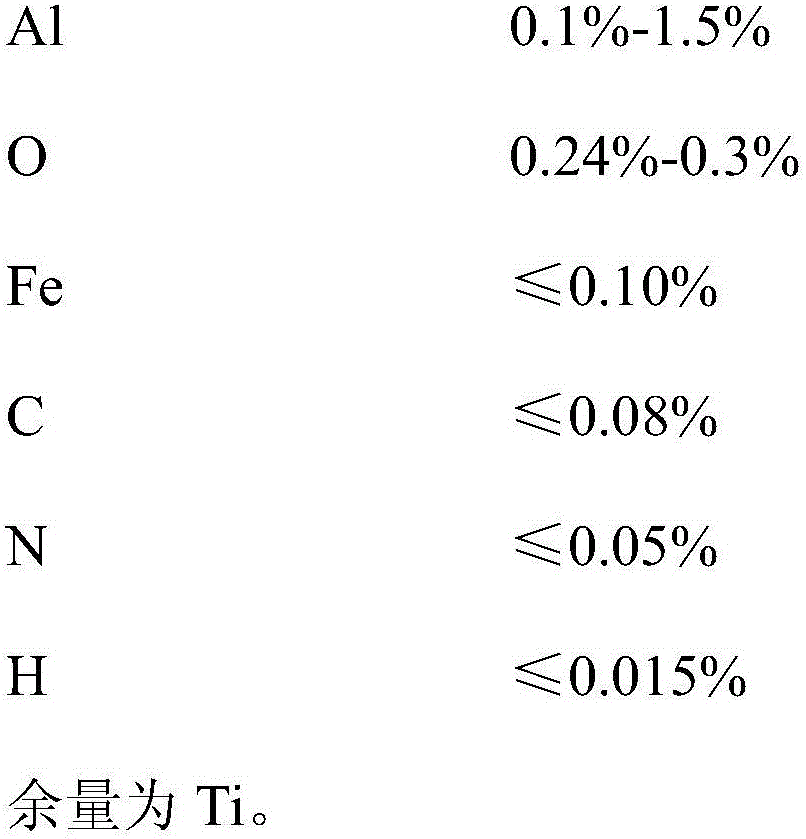

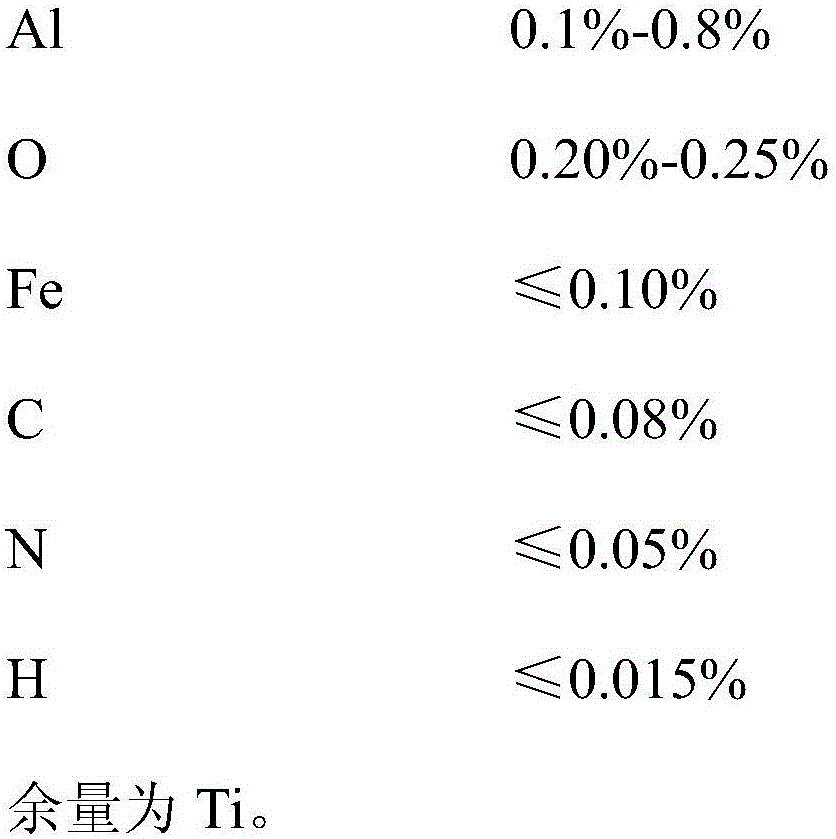

[0076] Dosing according to the following components:

[0077] Al 1.2%; O 0.27%; the balance is Ti.

[0078] The specific preparation method is:

[0079] After batching, it is smelted in a vacuum consumable electrode electric arc furnace, and is cooled by cooling circulating water while melting to obtain an alloy ingot; the alloy ingot is forged into a rod and then machined into a φ235mm smooth rod, and then its polished rod Put it into an electric heating furnace for heating, raise the temperature to 910°C, and keep it warm for 160 minutes. After the bar is out of the furnace, it is pierced with a cross-rolling piercer at a piercing speed of 23mm per second; into the soaking furnace and heated at 800°C for 20 minutes; after coming out of the furnace, it enters the hot rolling pipe mill with a rolling speed of 45mm / s; Outer diameter, the sizing rolling speed is 90mm per second, after sizing, it is sent to the heating furnace for annealing, kept at 650°C for 120min, and cooled...

Embodiment 3

[0081] Dosing according to the following components:

[0082] Al 2.4%; O 0.32%; the balance is Ti.

[0083] The specific preparation method is:

[0084] After batching, it is smelted in a vacuum consumable electrode electric arc furnace, and is cooled by cooling circulating water while melting to obtain an alloy ingot; after the alloy ingot is forged into a bar, it is machined into a φ105mm smooth rod, and then its polished rod Put it into an electric heating furnace for heating, raise the temperature to 960°C, and keep it warm for 110 minutes. After the bar is out of the furnace, it is pierced with a cross-rolling piercer at a piercing speed of 30mm per second; Send it into the soaking furnace and heat it at 780°C for 30 minutes; after it comes out of the furnace, it enters the hot rolling pipe mill with a rolling speed of 60mm / s; The outer diameter is determined, and the rolling speed of the sizing is 120mm per second. After the sizing, it is sent to the heating furnace fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com