A kind of palladium carbon catalyst and its preparation method and application

A palladium-carbon catalyst, a catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, hydrocarbons, etc., can solve the problems of catalyst deactivation, aggravated coking and cracking, etc., to inhibit coking, reduce hydrogen consumption, The effect of eliminating strong acid centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The HC support was treated with NaOH.

[0039] Weigh 1.0 g of HC, add it to 20 mL of NaOH aqueous solution (1 mol / L), and stir at room temperature for 48 hours. After filtration, the obtained solid was fully washed with deionized water until the liquid was neutral, and then dried in a vacuum oven at 95° C., and the obtained carrier was recorded as NaC. The mass content of Na measured by inductively coupled plasma atomic emission spectrometry was 3.1%. The specific surface area of NaC is shown in table 1 below, as can be seen from table 1, the specific surface area of NaC (284m 2 / g) significantly lower than AC (560m 2 / g). pH of NaC PZC The value is basic (9.61). NaOH treatment converted a large number of acidic oxygen-containing functional groups in HC to basic oxygen-containing functional groups. The carboxyl and lactone functional groups were almost completely eliminated, and the phenolic hydroxyl groups were reduced by about half. However, the content of ...

Embodiment 2

[0041] The HC support was treated with KOH.

[0042] Weigh 1.0 g of HC, add it to 20 mL of KOH aqueous solution (1 mol / L), and stir at room temperature for 48 hours. After filtration, the obtained solid was fully washed with deionized water until the liquid was neutral, and then dried in a vacuum oven at 95° C., and the obtained carrier was designated as KC. The mass content of K measured by inductively coupled plasma atomic emission spectrometry was 4.1%. The specific surface area of KC is shown in Table 1 below, as can be seen from Table 1, the specific surface area of KC (234m 2 / g) significantly lower than AC (560m 2 / g). pH of KC PZC The value is basic (9.49). KC still contains a small amount of carboxyl groups. Compared with HC, the content of lactone group and carbonyl group increased, while the number of phenolic hydroxyl group decreased significantly. The total content of basic oxygen-containing functional groups and acidic oxygen-containing functional grou...

Embodiment 3

[0046] Preparation of Supported Pd Catalyst

[0047] The supported Pd catalyst precursor was prepared by equal-volume impregnation: first, the metered PdCl 2 Dissolve in metered dilute HCl solution (0.4mol / L), impregnate respectively on the activated carbon carrier (AC, HC, NaC or KC) prepared above at room temperature. After standing at room temperature for 8 hours, the catalyst precursor was obtained by drying in a vacuum oven at 95°C.

[0048] 0.05 g of the obtained catalyst precursor was pressed into tablets and crushed to 20-40 meshes, placed in a fixed-bed reactor with an inner diameter of 8 mm, and a supported Pd catalyst was prepared by a temperature-programmed reduction method. The specific conditions are as follows: in a hydrogen atmosphere with a total pressure of 1.0MPa, the temperature is raised from room temperature to 300°C at a rate of 10°C / min, and the gas flow rate is 75NmL / min. Pd catalyst. The mass content of Pd in the catalyst is 0.5%.

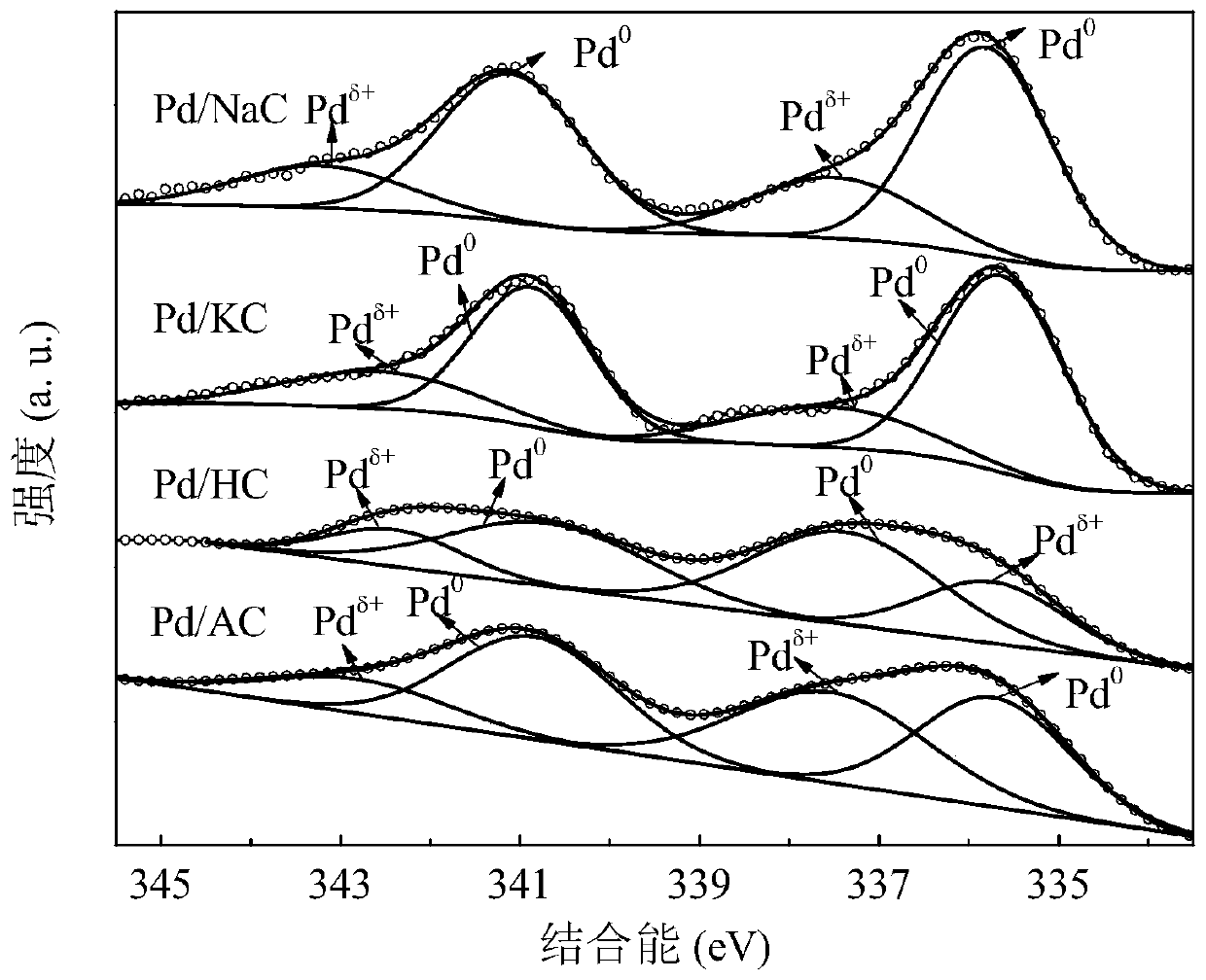

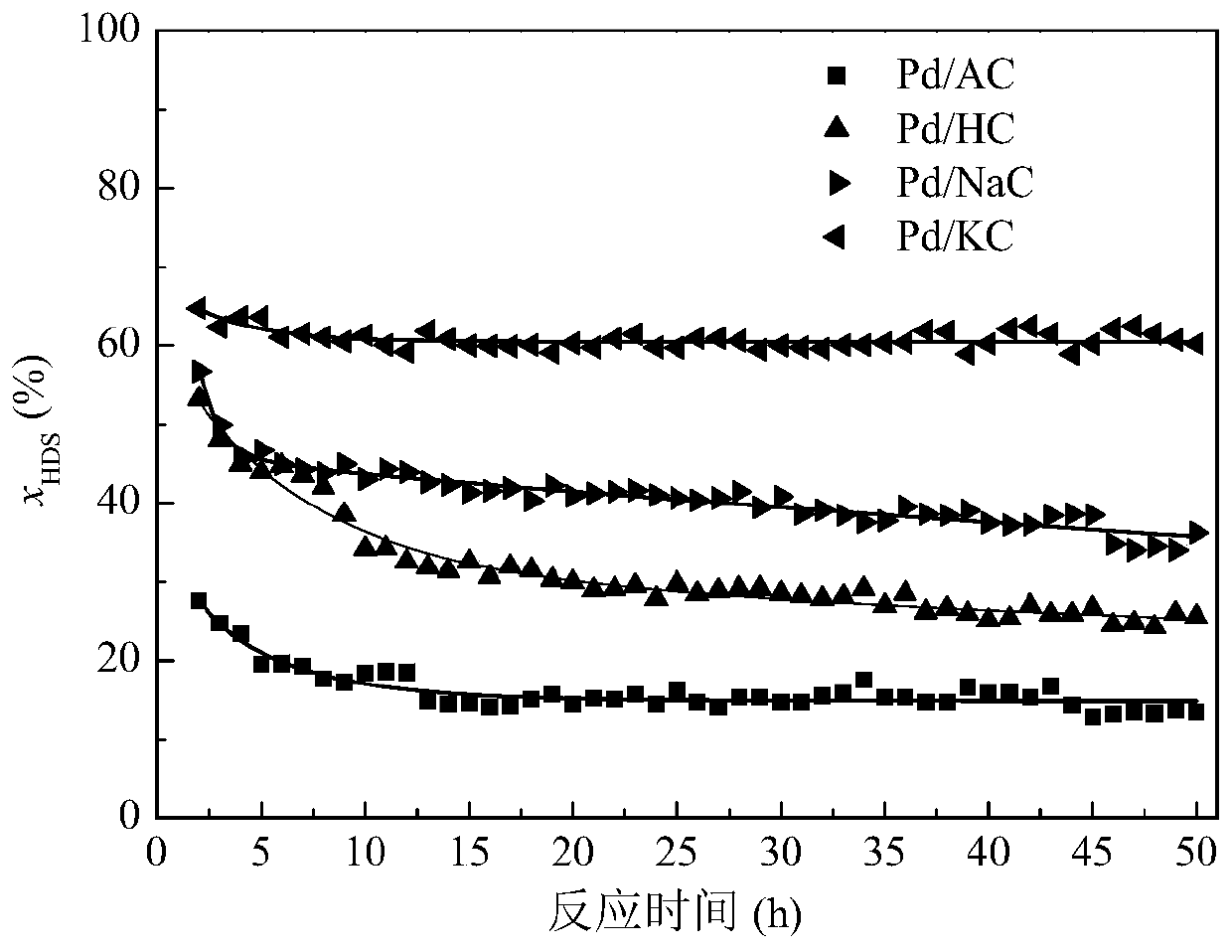

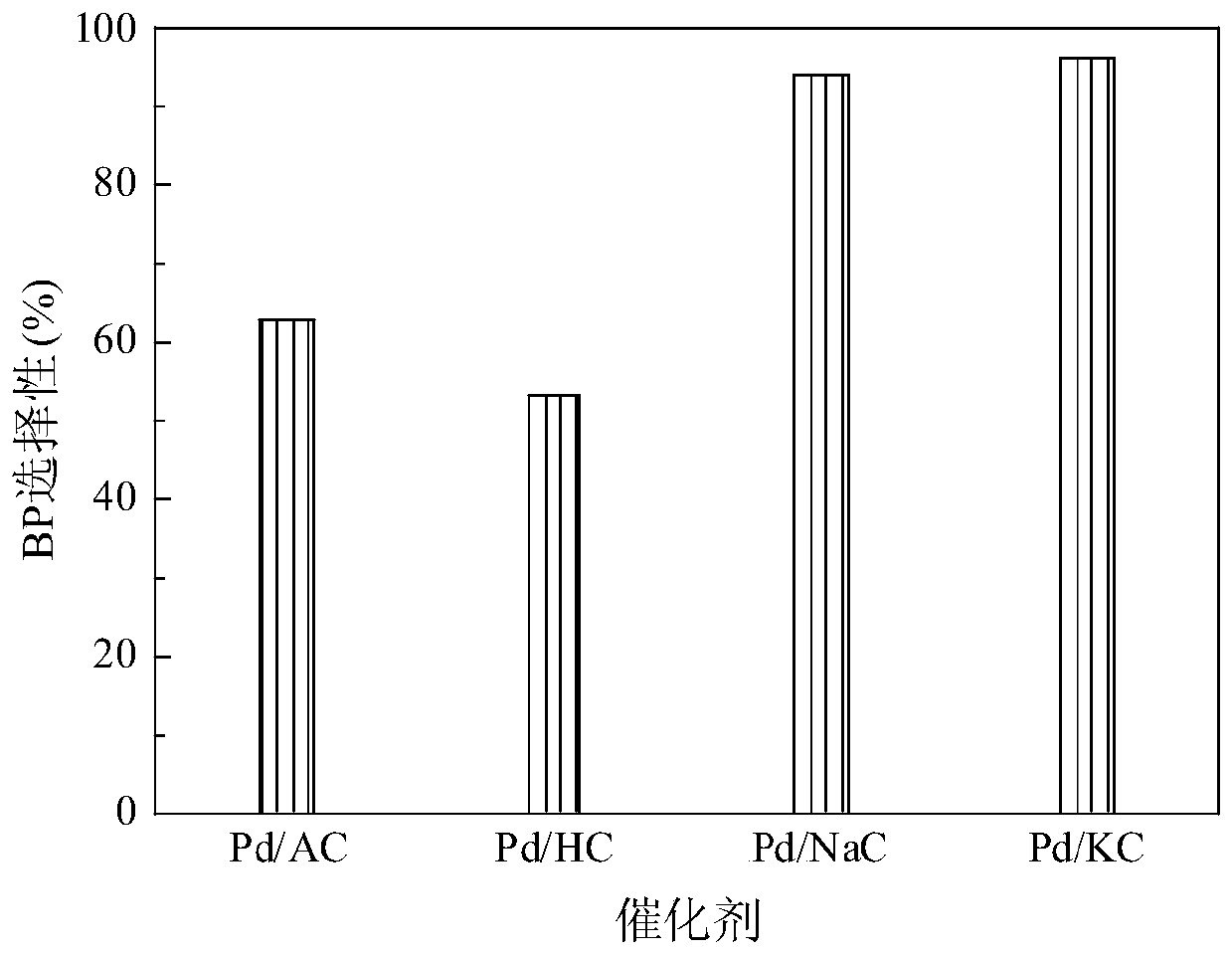

[0049] The X...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com