Ultra-precision grinding machine tool for small-size thin-walled complicated structure part

A complex structure, ultra-precision technology, applied in the direction of grinding machine parts, grinding frame, grinding machine bed, etc., can solve the problems of ultra-precision grinding processing difficulties, to ensure the grinding quality, achieve ultra-precision Grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

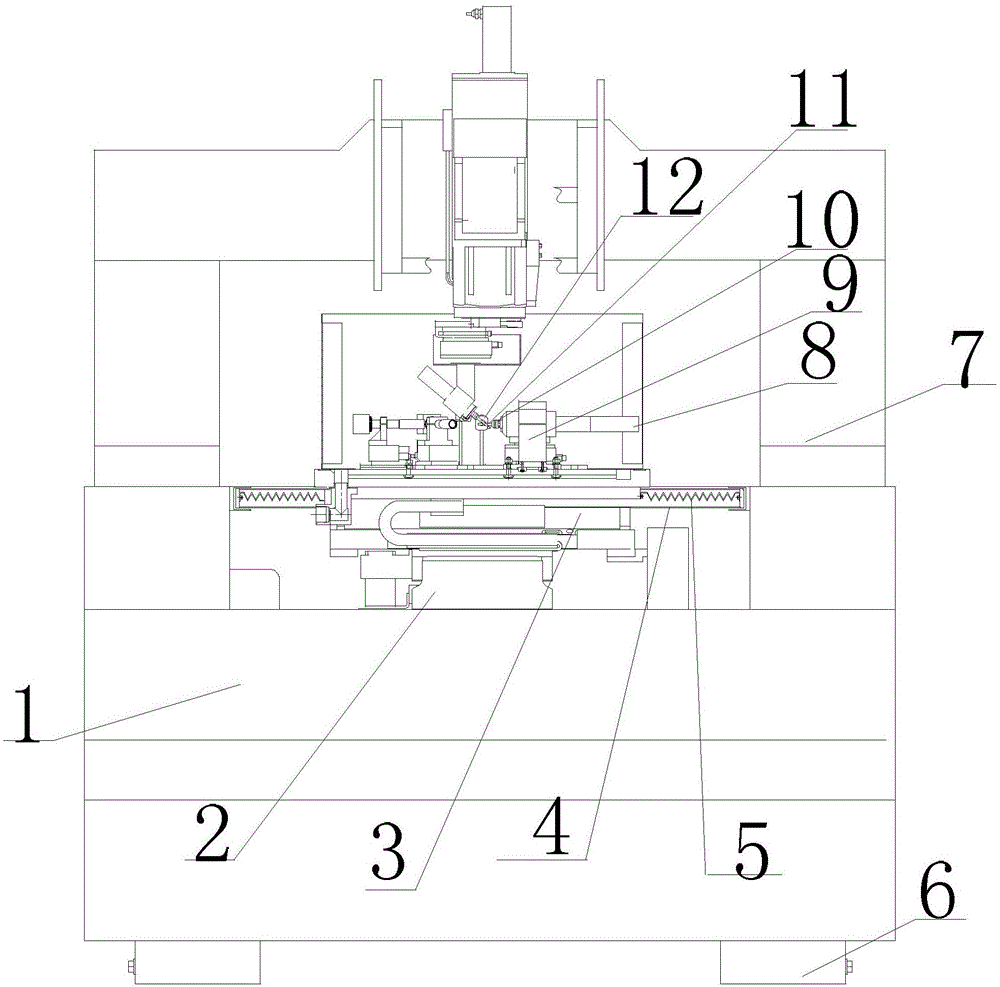

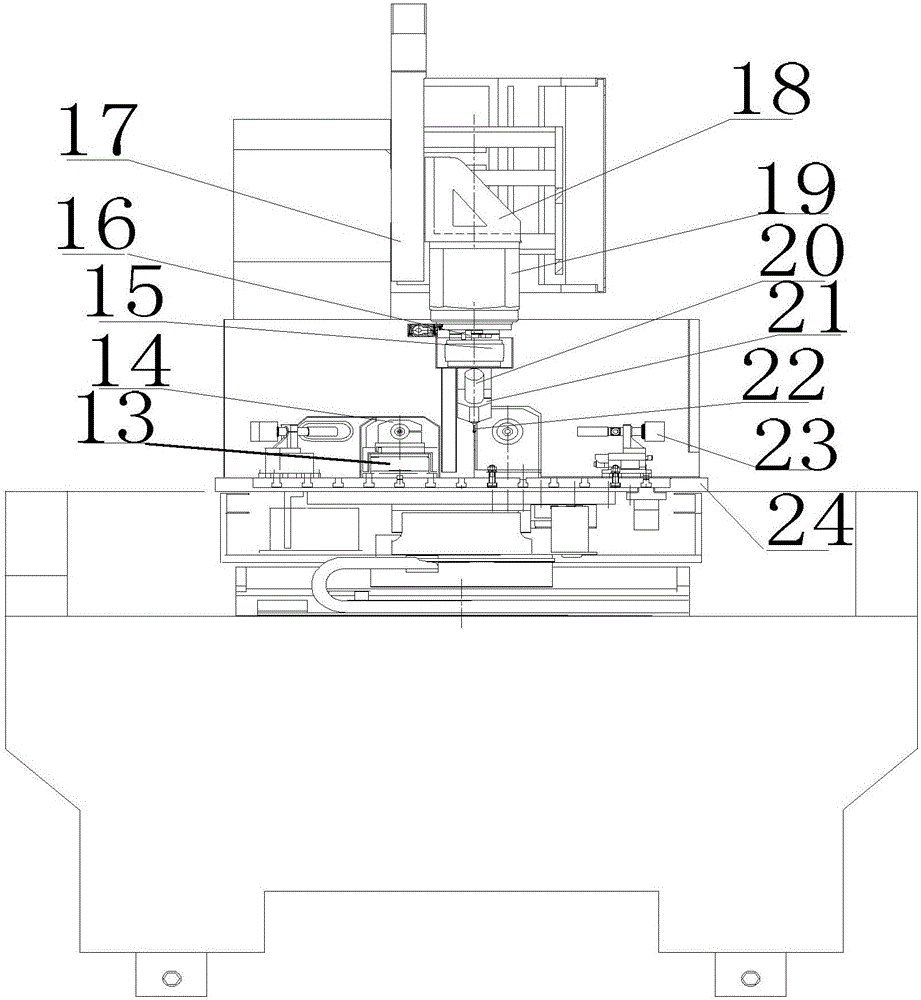

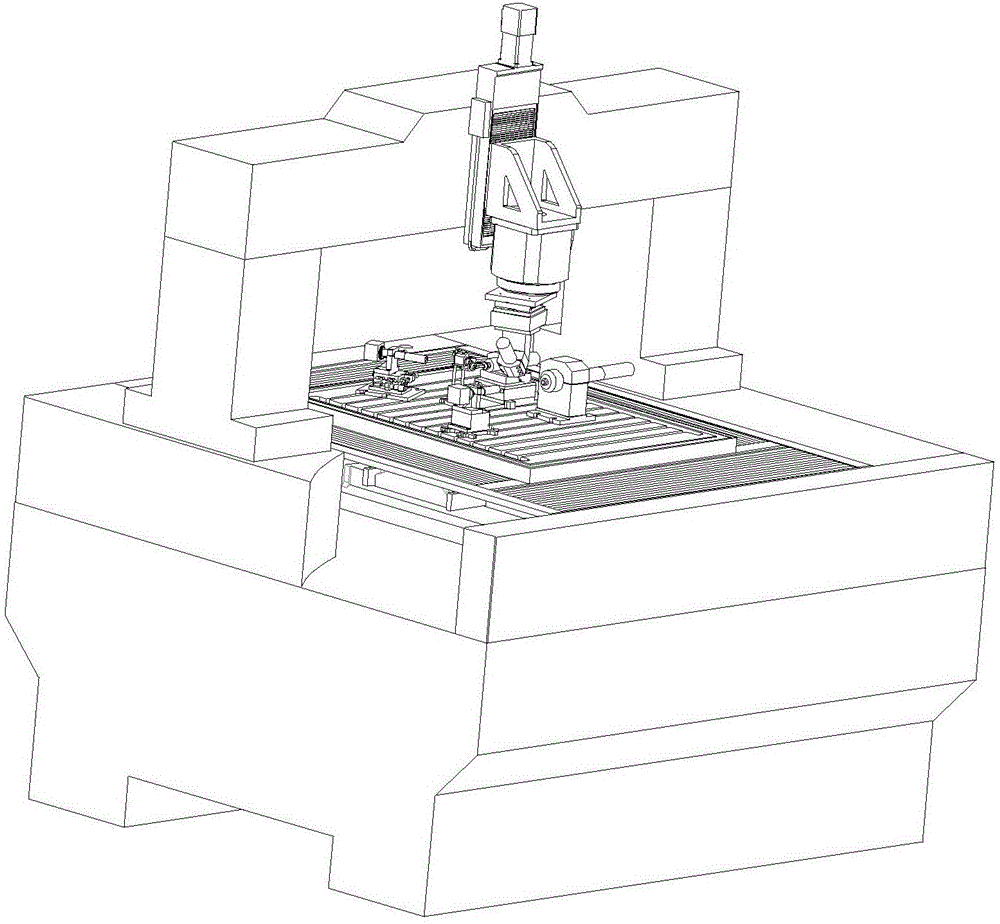

[0019] Specific implementation mode 1. Combination Figure 1 to Figure 3 Describe this embodiment, the machine tool for ultra-precision grinding of small-sized thin-walled complex structural parts described in this embodiment, it includes a machine tool base 1, a Y-axis linear motion platform 2, an X-axis linear motion platform 3, and an organ shield bracket 4. Organ protective cover 5, vertical structural parts 7, workpiece spindle 8, workpiece spindle fixing device 9, dressing electrode spindle 10, EDM dressing tool electrode 11, EDM dressing power supply device 12, ultra-precision linear motion platform 13, dressing Electrode spindle fixing device 14, ultra-precise linear positioning platform 15, one-dimensional precision fine-tuning displacement platform 16, Z-axis motion platform 17, turntable connector 18, direct drive precision turntable 19, grinding wheel spindle 20, grinding wheel spindle fixing device 21, small diameter Hemispherical head grinding wheel 22, CCD tool ...

specific Embodiment approach 2

[0031] Specific embodiment 2. This embodiment is a further description of the machine tool for ultra-precision grinding of small-sized thin-walled complex structural parts described in specific embodiment 1 or 2. The stroke of the Y-axis linear motion platform 2 is 300mm, and the positioning accuracy is ±0.5μm, straightness is 2.25μm.

specific Embodiment approach 3

[0032] Specific embodiment three. This embodiment is a further description of the machine tool for ultra-precision grinding of small-sized thin-walled complex structural parts described in specific embodiment one or two. The stroke of the X-axis linear motion platform 3 is 200mm, and the positioning accuracy is ±0.5μm, straightness is 2.25μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com