Fenton process sewage treatment integrated device based on iron sludge reuse and method thereof

A sewage treatment method and sewage treatment technology, applied in water/sludge/sewage treatment, water/sewage treatment, light water/sewage treatment, etc., can solve the unstable quality of ferrous sulfate, secondary pollution, and quality change of effluent water Poor problems, to achieve the effect of dosing amount and power consumption, avoid secondary pollution, high recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

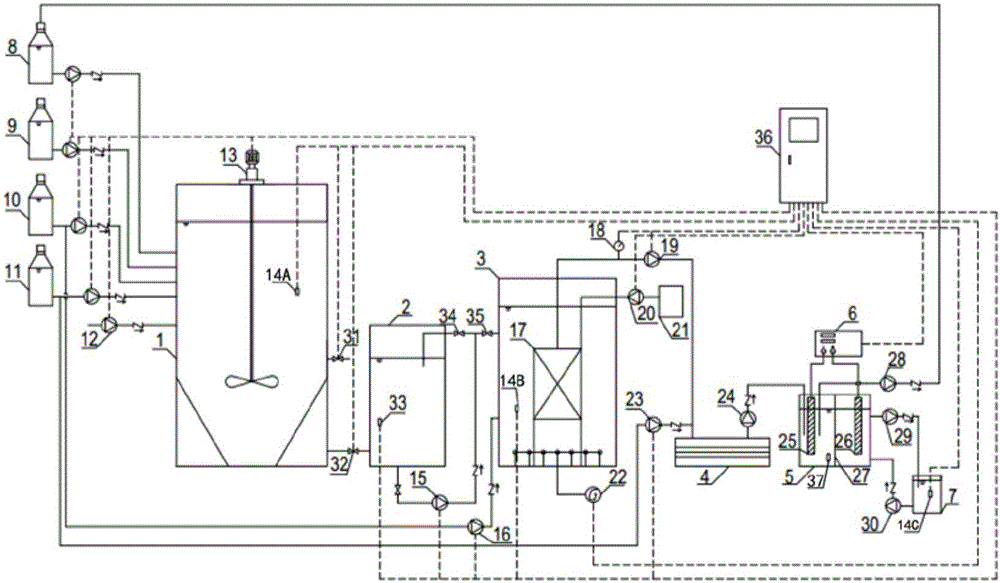

[0059] The inventor adopts as figure 1 The Fenton method wastewater treatment integrated device based on iron slime reuse is shown to carry out Fenton process treatment on a certain pharmaceutical intermediate production sewage. The average COD is 800mg / L, and further advanced treatment is required to meet the nanotube emission standard of COD≤500mg / L; the main steps of the Fenton process are:

[0060] 1) The raw water treated by the Fenton process is first pumped into the Fenton reaction tank 1 by the sewage inlet pump 12, and then it is operated in a sequence batch mode. The time for acid adjustment, reaction, alkali adjustment, and precipitation is 0.5h, 1.5h, 0.5h, and 0.5h, respectively. , wherein, the automatic control device 36 is used to control the water intake, the addition amount of each medicament, the stirring and settling time, the pH condition (the pH of the acid adjustment and alkali adjustment stages are respectively controlled to 3~4, 6~8) and drainage and mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com