High-content bacterium-coated biological fertilizer and preparation method thereof

A high-content, bio-fertilizer technology, applied in the field of bio-fertilizer, can solve the problems of low content of beneficial bacteria, excessive heavy metal content, low organic matter content, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

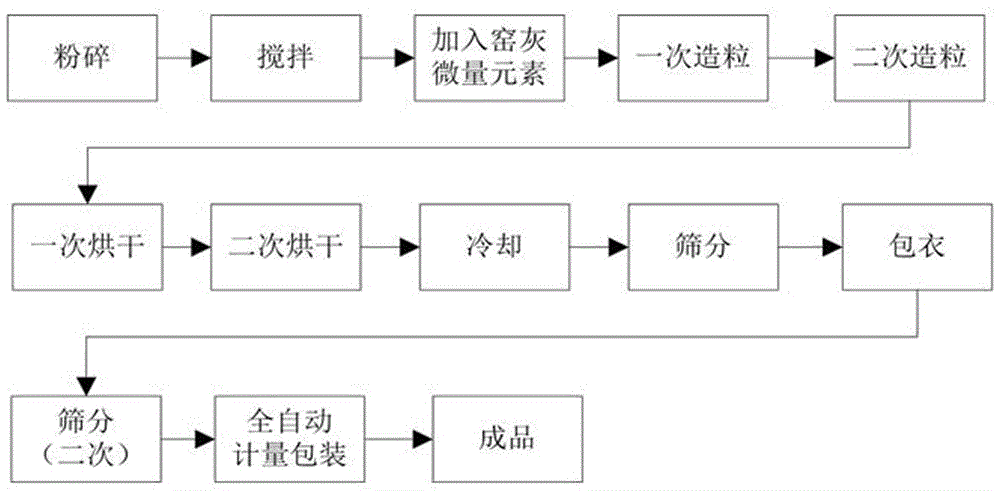

[0017] The present invention also provides a method for preparing the above-mentioned high-content bacteria-coated biological fertilizer, which includes the following steps: 1) pulverizing the decomposed furfural residue and humic acid; 2) adding kiln dust, zinc sulfate monohydrate, and boric acid for stirring; 3 ) After being uniformly stirred, it is transported to the drum granulator for granulation; 4) The second granulation is then carried out; 5) After the second granulation is transported to the dryer for drying; 6) The second drying is then carried out; 7 ) After the second drying, the material is transported to the cooler for cooling; 8) After cooling, the material is screened; 9) The sieved material is transported to the bacteria coating machine, and it is combined with Bacillus subtilis, Bacillus licheniformis, and jelly spores. Bacillus is coated; 10) the coated materials are screened a second time; 11) after the second screening, the materials are transported to the ...

Embodiment 1

[0023] High-content bacteria-coated biological fertilizer formula: 700kg of furfural residue, 200kg of humic acid, 80kg of kiln dust, 10kg of Bacillus subtilis, 2kg of Bacillus licheniformis, 5kg of Bacillus jelly, 5kg of zinc sulfate monohydrate, 5kg of boric acid.

[0024] The preparation method of the high-content bacteria-coated biological fertilizer includes the following steps: 1) pulverize the decomposed furfural residue and humic acid; 2) add kiln dust, zinc sulfate monohydrate, and boric acid to stir; 3) stir evenly Transported to the drum granulator for granulation; 4) followed by secondary granulation; 5) after secondary granulation, transported to the dryer for drying, the inlet temperature of the dryer is 150°C; 6) followed by Second drying; 7) After the second drying, the material is transported to the cooler for cooling; 8) After cooling, the material is screened; 9) The screened material is transported to the bacteria coating machine, and it is combined with Bacill...

Embodiment 2

[0026] High-content bacteria-coated biological fertilizer formula: furfural residue 750kg, humic acid 220kg, kiln dust 75kg, Bacillus subtilis 5kg, Bacillus licheniformis 3kg, Bacillus jelly 6kg, zinc sulfate monohydrate 5kg, boric acid 3kg.

[0027] The preparation method of the high-content bacteria-coated biological fertilizer includes the following steps: 1) pulverize the decomposed furfural residue and humic acid; 2) add kiln dust, zinc sulfate monohydrate, and boric acid to stir; 3) stir evenly Conveyed to the drum granulator for granulation; 4) followed by secondary granulation; 5) after secondary granulation, transported to the dryer for drying, the inlet temperature of the dryer is 180℃; 6) followed by Second drying; 7) After the second drying, the material is transported to the cooler for cooling; 8) After cooling, the material is screened; 9) The screened material is transported to the bacteria coating machine, and it is combined with Bacillus subtilis and lichen Bacil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com