Application of lower molecular weight Y-type hydrophilic group amphiphilic molecule compound in the aspect of improving viscosity and stability of asphalt emulsion

A low-molecular-weight, amphiphilic molecule technology, which is applied in building structures, building components, building insulation materials, etc., can solve problems such as corrosion, colloidal grinding heads and pipeline entanglement, inconvenient production and use, etc., to achieve increased viscosity and stability performance, stability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

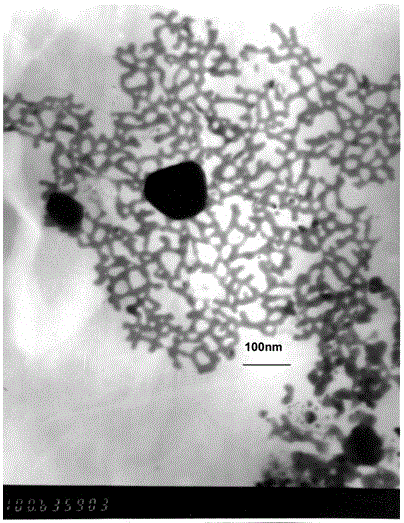

Image

Examples

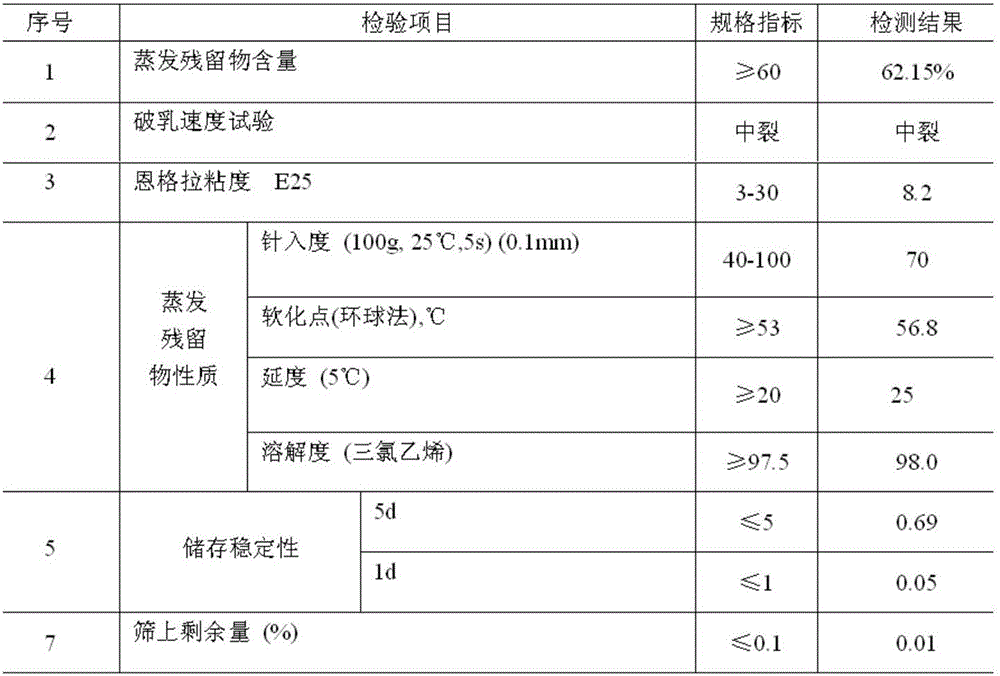

Embodiment 1

[0050] The application of a low-molecular-weight Y-type hydrophilic amphiphile compound in improving the viscosity and stability of asphalt emulsion, the molecular weight of the low-molecular-weight Y-type amphiphile compound is 271, and its structural formula is :

[0051] where R 1 It is a straight chain alkane with molecular formula CnHm, wherein n is 14 and m is 29;

[0052] M is N;

[0053] X is O;

[0054] R 2 In the molecular formula CxHyOz, x is 0, y is 1, and z is 0;

[0055] R 3 In the molecular formula CxHyOz, x is 0, y is 1, and z is 0;

[0056] R 4 is the molecular formula (CH 2 ) substituent of n, n is 3.

[0057] The application of above-mentioned a kind of low molecular weight Y-type hydrophilic group amphiphile compound aspect improving bitumen emulsion viscosity and stability, concrete steps are as follows:

[0058] (1), preparation of soap solution containing low molecular weight Y-type hydrophilic group amphiphile compound

[0059] Heat 360g of...

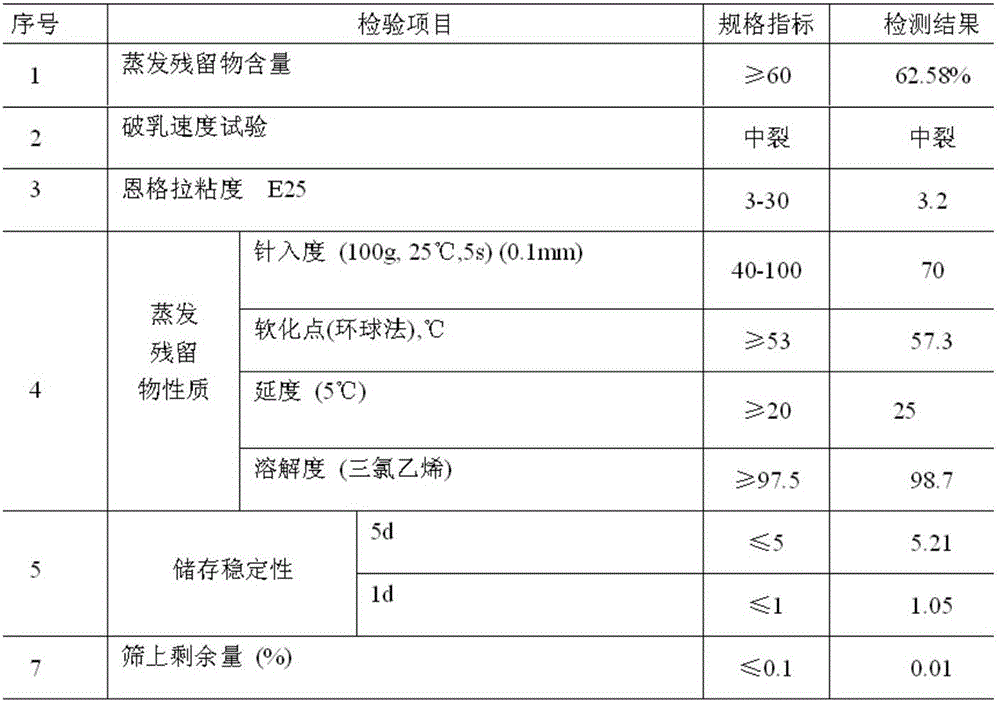

Embodiment 2

[0068] The application of a low molecular weight Y-type hydrophilic group amphiphile compound in improving the viscosity and stability of asphalt emulsion is characterized in that the molecular weight of the low molecular weight Y-type hydrophilic group amphiphile compound is 358, Its structural formula is:

[0069] R 1 It is a straight chain alkane with molecular formula CnHm, wherein n is 14 and m is 29;

[0070] M is N;

[0071] X is NH;

[0072] R 2 In the molecular formula CxHyOz, x is 2, y is 5, and z is 1;

[0073] R 3 In the molecular formula CxHyOz, x is 2, y is 5, and z is 1;

[0074] R 4 is the molecular formula (CH 2 ) substituent of n, n is 3.

[0075] The application of above-mentioned a kind of low molecular weight Y-type hydrophilic group amphiphile compound aspect improving bitumen emulsion viscosity and stability, concrete steps are as follows:

[0076] In addition to the deionized water in the step (2), the mass percentage concentration is 28% in...

Embodiment 3

[0078] The application of a low-molecular-weight Y-type hydrophilic amphiphile compound in improving the viscosity and stability of asphalt emulsions, the molecular weight of the low-molecular-weight Y-type amphiphile compound is 721, and its structural formula is :

[0079] where R 1 It is a straight chain alkane with molecular formula CnHm, wherein n is 14 and m is 29;

[0080] M is N;

[0081] X is O;

[0082] R 2 In the molecular formula CxHyOz, x is 12, y is 25, and z is 4;

[0083] R 3 In the molecular formula CxHyOz, x is 12, y is 25, and z is 4;

[0084] R 4 is the molecular formula (CH 2 )n substituent, n is 2.

[0085] The application of above-mentioned a kind of low molecular weight Y-type hydrophilic group amphiphile compound aspect improving bitumen emulsion viscosity and stability, concrete steps are as follows:

[0086] In addition to the deionized water in the step (2), the mass percentage concentration is 28% industrial hydrochloric acid aqueous so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com