Preparation method of flexible polyaniline conductive composite hydrogel material

A composite hydrogel and polyaniline-based technology, which is applied in the field of preparation of flexible polyaniline-based conductive composite hydrogel materials, can solve the problems of insufficient preparation methods, weakened electrochemical properties of conductive active materials, and insufficient mechanical strength of hydrogels and other problems, to achieve the effect of improving electrochemical performance and mechanical strength, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the in-situ polymerization of PAni hydrogel in PVA aqueous solution

[0015] Weigh 10g of PVA into a 250ml three-neck flask, add 90ml of deionized water, stir and swell at 35°C for 0.5h, transfer to a 95°C oil bath and stir to dissolve completely, then cool the PVA aqueous solution to 4°C; 5%, 7.5% and 10% three groups of PVA aqueous solutions respectively nine parts to different beakers, respectively add 2.3ml phytic acid (50%, 4 ℃) and stir evenly, then add aniline (distillation, 4 ℃) in every group of solutions ℃), aniline / phytic acid=2:1, 4:1, 6:1, stirred rapidly until the white precipitate disappeared, and obtained nine kinds of mixed solutions with different ratios of PVA, aniline and phytic acid; at 4°C, the Add APS solution (4°C) quickly, aniline / APS=1:1, 3:1, 5:1, stir vigorously, the solution gradually turns dark green, and the viscosity increases.

Embodiment 2

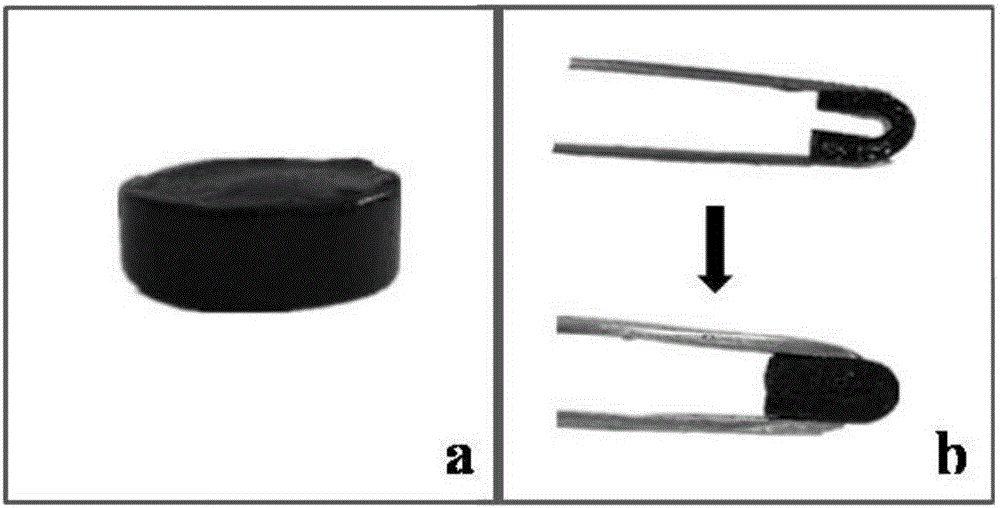

[0016] Embodiment 2, the preparation of flexible PVA-PAni composite hydrogel

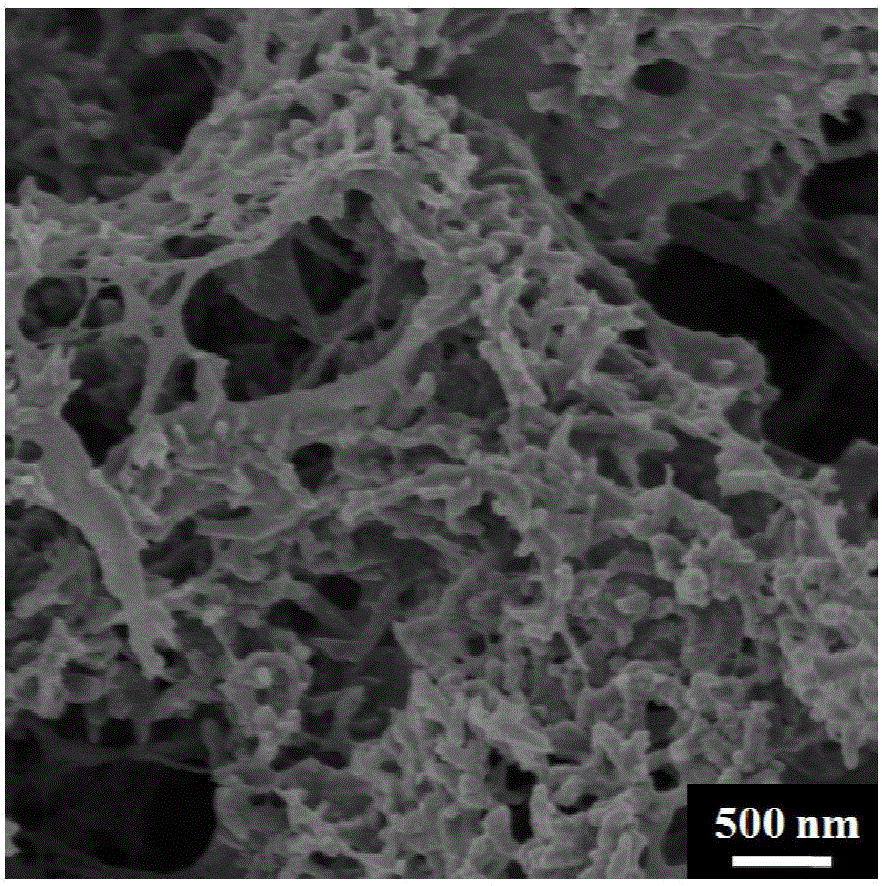

[0017] Freeze the mixture of dark green PAni hydrogel and PVA aqueous solution at -20°C for 18 hours, the PVA crystallizes to form a three-dimensional porous network structure, and then place it at room temperature for 6 hours to fully thaw the water and amorphous PVA molecules, and cycle more than 3 times to form The flexible PVA-PAni composite hydrogel was soaked in deionized water for 3 days to remove unreacted small molecules and impurities to obtain a flexible polyaniline-based conductive composite hydrogel material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com