Sodium lignosulfonate grafted magnesium-aluminum-based layered double hydroxide modifier, UV aging resistant SBR modified asphalt and preparation method thereof

A technology of sodium lignosulfonate and double hydroxide, applied in building structures, building components, building insulation materials, etc., can solve the problems of affecting UV protection, poor compatibility with asphalt, aging, etc., and achieve excellent UV resistance. Light aging ability, improving UV aging resistance, and remarkable effect of anti-ultraviolet aging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

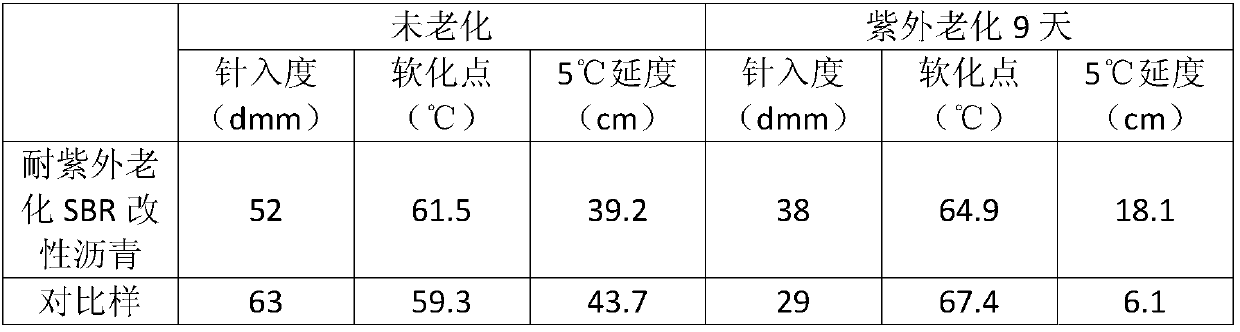

[0022] Heat 95 parts (parts by mass, the same below) of SBR modified asphalt (with a penetration of 63dmm at 25°C and a softening point of 59.3°C) to 160°C, and add the above-mentioned sodium lignosulfonate grafted magnesium-aluminum-based layered double hydroxide 5 parts of the material modifier, start the high-speed shearing machine, stir at a high speed at 4000 rpm for 1 hour, and keep the temperature at 160 ℃ ± 5 ℃ to obtain the UV aging resistant SBR modified asphalt.

[0023] The ultraviolet aging resistant SBR modified asphalt and the original SBR modified asphalt (comparative sample) were subjected to an ultraviolet accelerated aging test (ultraviolet light intensity is 1200μW / cm 2 , The temperature is 60℃, the aging time is 9 days, the same below), and then test its penetration (reflecting the softness and consistency of asphalt, and the ability to resist shear damage), softening point (reflecting the high temperature resistance of asphalt to deformation ) And 5℃ ductilit...

Embodiment 2

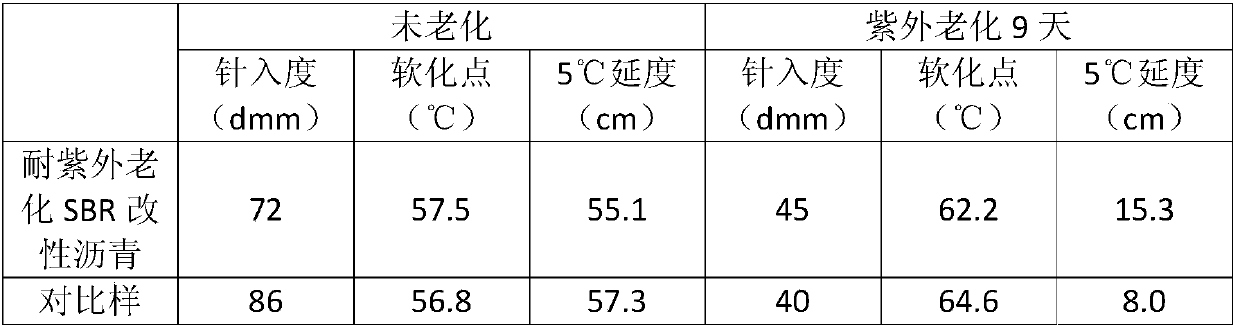

[0028] According to parts by mass, heat 97 parts of SBR modified asphalt (with a penetration of 86dmm at 25°C and a softening point of 56.8°C) to 160°C, and add the above-mentioned sodium lignosulfonate grafted magnesium-aluminum-based layered double hydroxide to modify 3 parts of the agent, start the high-speed shearing machine, stir at a high speed at 4000 rpm for 1 hour, and keep the temperature at 160°C±5°C to obtain the UV-resistant aging SBR modified asphalt.

[0029] The ultraviolet aging resistant SBR modified asphalt and the original SBR modified asphalt (comparative sample) were subjected to an ultraviolet accelerated aging test, and then the penetration, softening point and 5°C ductility were tested respectively. The test results are listed in Table 2.

[0030] Table 2 Performance changes before and after UV aging of SBR modified asphalt and comparison samples

[0031]

[0032] Through comparison, it can be seen that after UV aging, the penetration decrease value, softenin...

Embodiment 3

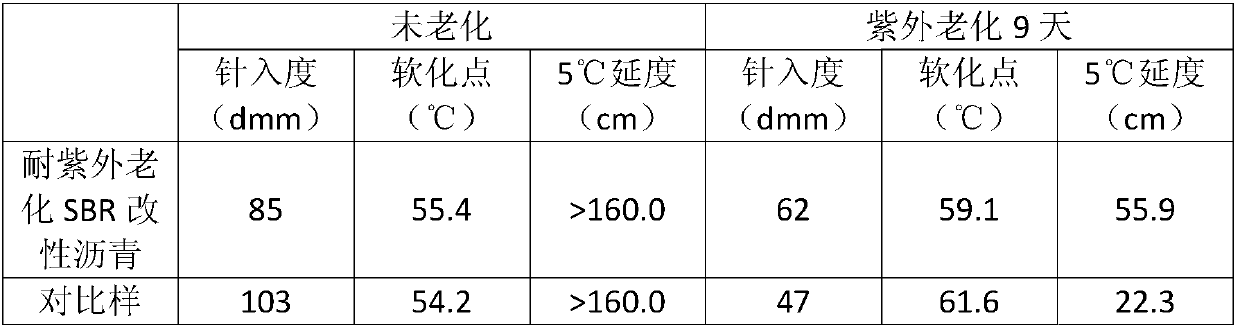

[0034] According to parts by mass, heat 96 parts of SBR modified asphalt (with a penetration degree of 103dmm at 25°C and a softening point of 54.2°C) to 160°C, and add the above-mentioned sodium lignosulfonate grafted magnesium-aluminum-based layered double hydroxide to modify 4 parts of the agent, start the high-speed shearing machine, stir at a high speed at 4000 rpm for 1 hour, and keep the temperature at 160 ℃ ± 5 ℃, then the UV aging resistant SBR modified asphalt is prepared.

[0035] The ultraviolet aging resistant SBR modified asphalt and the original SBR modified asphalt (comparative sample) were subjected to an ultraviolet accelerated aging test, and then the penetration, softening point and 5°C ductility were tested respectively. The test results are listed in Table 3.

[0036] Table 3 Performance changes before and after UV aging of SBR modified asphalt and comparison samples

[0037]

[0038] Through comparison, it can be seen that after UV aging, the decrease in penetr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com