Multi-graded anti-wearing hydraulic oil composition and preparation method thereof

A hydraulic oil composition and anti-wear hydraulic oil technology, which is applied in the field of hydraulic oil, can solve problems such as conflicts in oxidation stability, insufficient oxidation stability, and poor low-temperature fluidity, and achieve low cost, good wear resistance, and good viscosity. The effect of thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

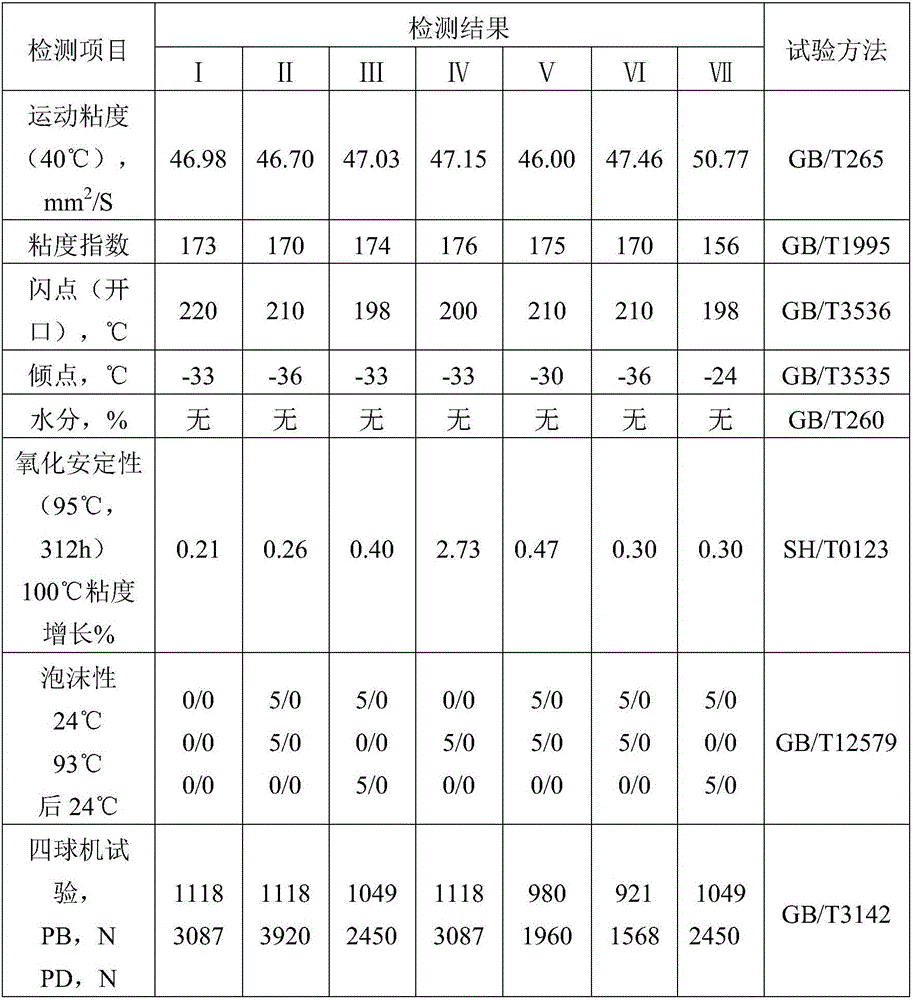

Examples

preparation example Construction

[0043]The present invention also provides a preparation method of the above-mentioned multi-stage anti-wear hydraulic oil, the steps are as follows:

[0044] (1) Add base oil into the reaction kettle, heat to 50°C-60°C, then add viscosity modifier, antioxidant, detergent and dispersant in sequence, stir evenly and keep warm for 1 hour;

[0045] (2) Then add the extreme pressure antiwear agent, and stir quickly to make it evenly dispersed;

[0046] (3) Add the composite antifoaming agent, stir evenly, cool to room temperature, and obtain the finished composition after filtering.

Embodiment 1

[0050] Add 88.485 parts of 150N (Korean Ssangyong Petrochemical Co., Ltd., brand: Ultra-S6, the same below) into a stainless steel blending kettle with a stirrer, keep the temperature of the kettle at 60°C, and then add 3 parts of polymethacrylate ( Shanghai Hersbit Chemical Co., Ltd., the same below), 1.5 parts of polyisobutylene (Shanghai Daopu Chemical International Trade Co., Ltd., the same below), 1 part of zinc dialkyldithiophosphate (Lubrizol Lan Refining Co., Ltd., below The same), 2 parts of 2,6-di-tert-butyl-p-cresol (VanderbiltChemicals, brand: VANLUBE PCX, the same below), 3.0 parts of low-alkali calcium petroleum sulfonate (Jinzhou Runda Chemical Co., Ltd., brand: T101 , the same below), stir evenly and keep warm for 1 hour. Then add 1.0 parts of nano-titanium dioxide (Shanghai Huan Titanium Chemical Co., Ltd., 50nm, the same below), and stir quickly to make it evenly dispersed, and then add 0.015 parts of composite antifoaming agent (Jinzhou Shengda Chemical Co.,...

Embodiment 2

[0052] Add 91.495 parts of 250N (South Korea Ssangyong Petrochemical Co., Ltd., brand: Ultra-S8, the same below) into a stainless steel blending kettle with a stirrer, keep the temperature of the kettle at 60°C, and then add 3 parts of polymethacrylate, 1 part of zinc dialkyl dithiophosphate, 1 part of 2,6-di-tert-butyl-p-cresol, 1.5 parts of polyisobutylene bis-succinimide (Shanghai Hersbit Chemical Co., Ltd., brand: T154, the same below ), stir well and keep warm for 1 hour. Then add 2.0 parts of nano-titanium dioxide, stir quickly to make it evenly dispersed, then add 0.005 part of composite antifoaming agent, stir evenly, cool to room temperature, and filter to obtain multi-stage hydraulic oil composition II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com