Production method for sand lined iron mould casting nodular cast iron bus installing plate

A technology of sand-coated iron mold casting and ductile iron, which is applied in casting molding equipment, molds, cores, etc., can solve the problems of unguaranteed overall mechanical properties, poor organizational properties, etc., and achieves elimination of subcutaneous pore defects and environmental protection. The effect of good performance and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the present invention is described in detail below, but it does not constitute a limitation to the protection scope of the claims of the present invention.

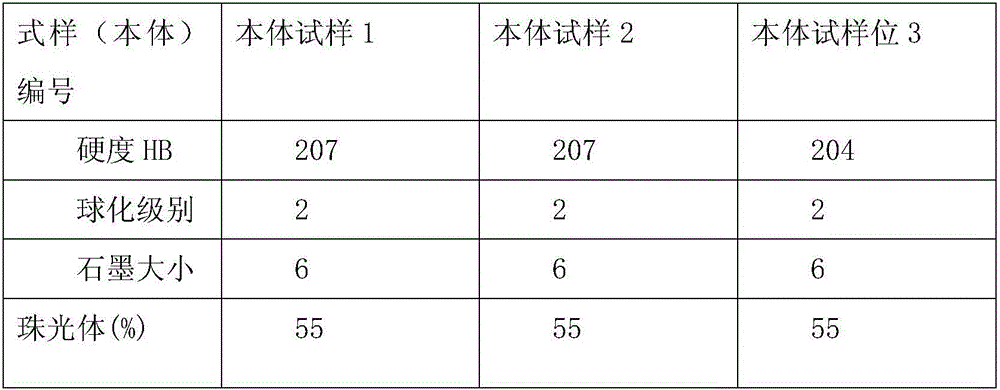

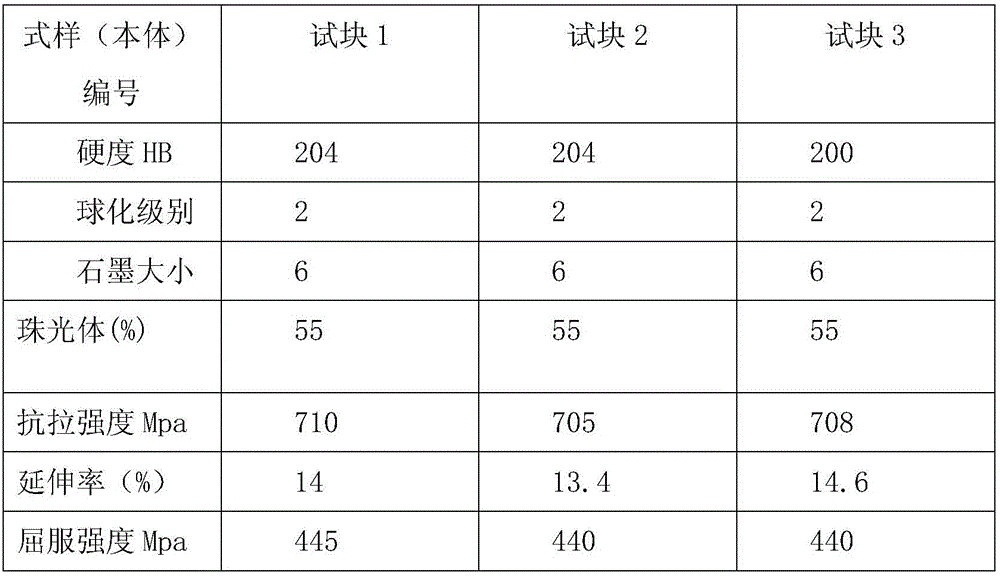

[0027] The iron mold sand-covered casting process uses iron molds to increase the cooling rate of molten iron during the casting process, refine the structure, and improve the compactness of the casting. Under the same composition of smelted molten iron, the production of nodular cast iron passenger car mounting plates and other products by iron mold sand-covered casting process can obtain higher tensile strength, yield strength, hardness and better graphite shape and graphite size grade than sand casting process , Stable pearlite is above 50%. The most important thing is that the problems of insufficient strength and shrinkage in the past can be effectively solved.

[0028] The iron mold sand-covered casting process of the passenger car mounting plate is different from the static pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com