High-frequency induction evaporation source device

A high-frequency induction, evaporation source technology, used in vacuum evaporation plating, ion implantation plating, metal material coating processes, etc., can solve the problems of uneven heating rate, cracking of evaporation materials, difficult heating of evaporation materials, etc. Avoids the effect of uneven heating rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

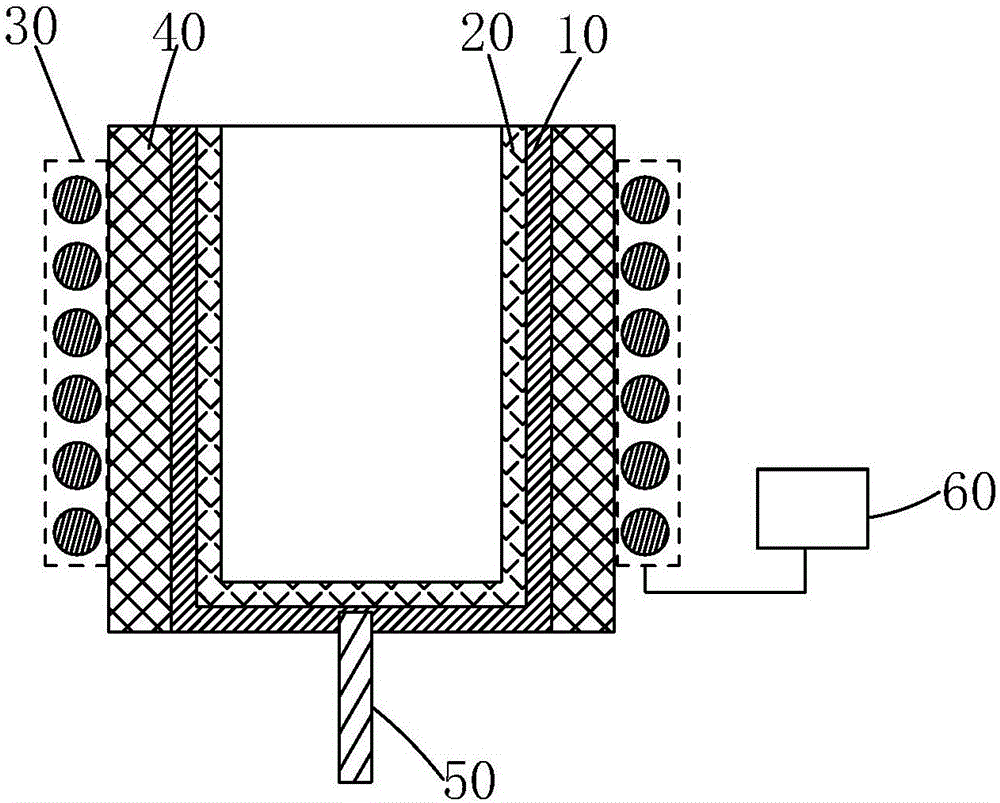

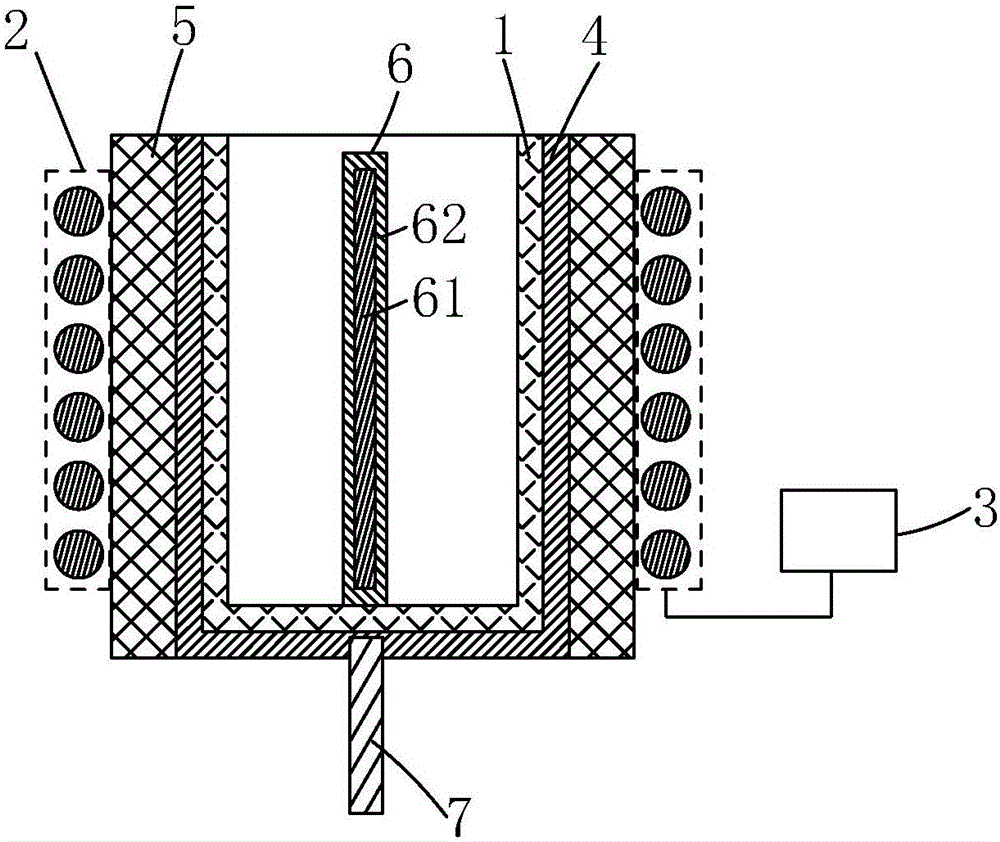

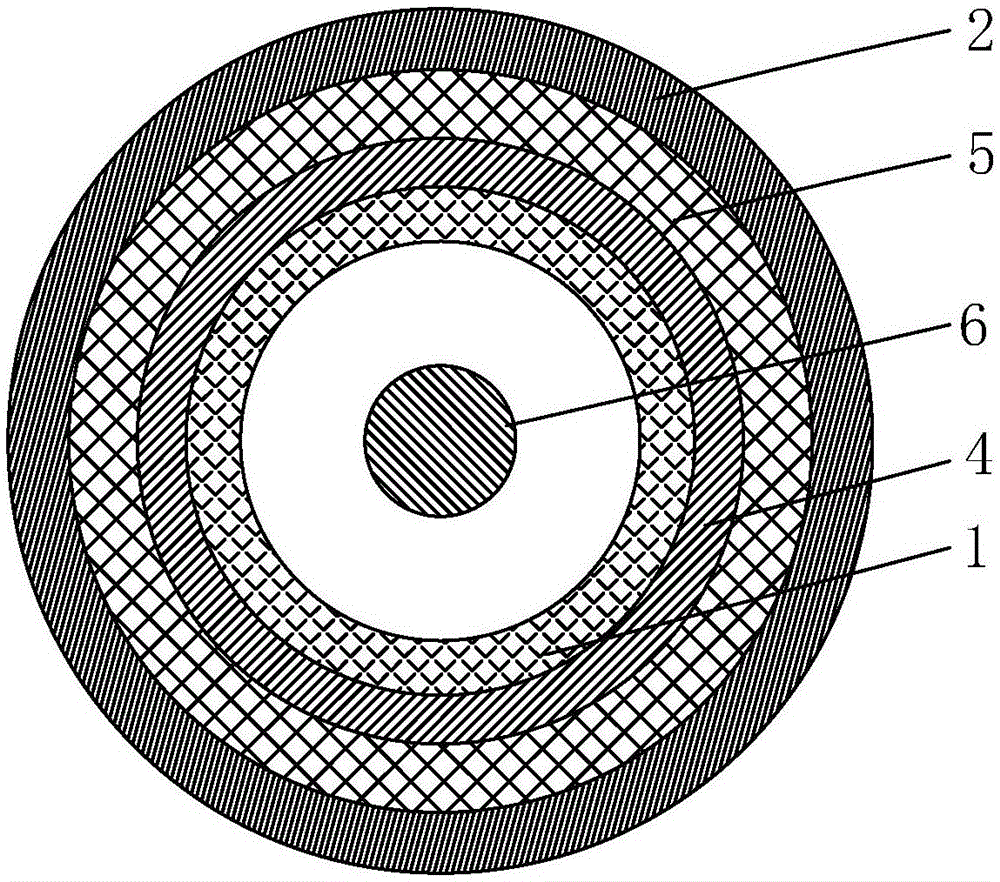

[0032] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

[0033] see figure 2 , the present invention provides a high-frequency induction evaporation source device, including an inner crucible 1 for carrying evaporation materials, an induction coil 2 sleeved on the periphery of the inner crucible 1, a radio frequency generator 3 connected to the induction coil 2, and A radio frequency induction heating component (High Frequency Induced Heater) 6 arranged in the inner crucible 1;

[0034] The induction coil 2 is used to receive the alternating current emitted by the radio frequency generator 3 to generate an induced magnetic field; An induced current is generated in the induced magnetic field and heat is generated, thereby heating the evaporation material.

[0035] The high-frequency induction evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com