A kind of preparation method of ag/tio2/au coating with trap structure

A technology of traps and coatings, applied in coatings, metal material coating processes, liquid chemical plating, etc., can solve the problems of poor environmental stability of trap structure silver, achieve improved secondary electron suppression characteristics, and good process stability , the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) Use 50mL of detergent, deionized water, acetone and ethanol in sequence to ultrasonically clean the silver-plated aluminum alloy with a size of 20mm in length, 12mm in width and 1mm in height, for 15 minutes each.

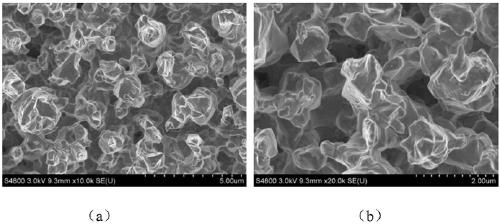

[0033] (2) adopt 12g mass fraction to be 20% Fe(NO 3 ) 3 Etch the silver-plated aluminum alloy after cleaning in step (1) with an aqueous solution. The etching temperature is 45°C and the etching time is 35s. Then, the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes. Dry in medium for 30min.

[0034] (3) adopt 12g mass fraction to be 20% Fe(NO 3 ) 3 Etch the silver-plated aluminum alloy dried in step (2) with an aqueous solution, the etching temperature is 45°C, and the etching time is 35s, then the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes, and finally dried in an oven at 50°C Dry in medium for 30min to form a trap structure on the surfa...

Embodiment 2

[0038] (1) Use 50mL of detergent, deionized water, acetone and ethanol in order to ultrasonically clean the silver-plated aluminum alloy with a size of 20mm in length, 12mm in width and 1mm in height, for 15 minutes each.

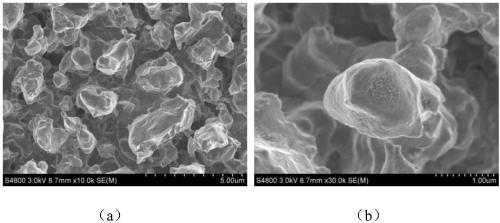

[0039] (2) adopt 12g mass fraction to be 40% Fe(NO 3 ) 3Etch the silver-plated aluminum alloy after cleaning in step (1) with an aqueous solution. The etching temperature is 55°C and the etching time is 45s. Then, the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes. Dry in medium for 30min.

[0040] (3) adopt 12g mass fraction to be 40% Fe(NO 3 ) 3 Etch the silver-coated aluminum alloy dried in step (2) with an aqueous solution. The etching temperature is 55°C and the etching time is 45s. Then, the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes. Dry in medium for 30min to form a trap structure on the surface of silver-plated aluminum alloy.

[0...

Embodiment 3

[0044] (1) Use 50mL of detergent, deionized water, acetone and ethanol in sequence to ultrasonically clean the silver-plated aluminum alloy with a size of 20mm in length, 12mm in width and 1mm in height, for 15 minutes each.

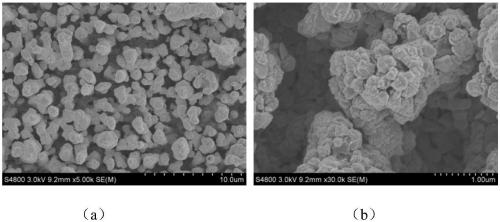

[0045] (2) adopt 12g mass fraction to be 30% Fe(NO 3 ) 3 Etch the silver-plated aluminum alloy after cleaning in step (1) with an aqueous solution. The etching temperature is 50°C and the etching time is 40s. Then, the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes. Dry in medium for 30min.

[0046] (3) adopt 12g mass fraction to be 20% Fe(NO 3 ) 3 Etch the silver-plated aluminum alloy after cleaning in step (2) with an aqueous solution. The etching temperature is 50°C and the etching time is 40s. Then, the silver-plated aluminum alloy is cleaned with deionized water and ultrasonically cleaned for 3 minutes. Dry in medium for 30min to form a trap structure on the surface of silver-plated aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com