Co-doped micro-sphere-carbon fiber composite material and preparation method thereof

A composite material and microsphere technology, which is applied in the fields of chemical characteristics of fibers, rayon manufacturing, textiles and papermaking, etc., can solve the problems of wide application of carbon micro-nanosphere composite materials, cumbersome process, expensive equipment, etc., and achieves low cost, The effect of easy availability of raw materials and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The present invention firstly provides a kind of preparation method of the microsphere-carbon fiber composite material of co-doping, and this method comprises the following steps:

[0030] Step 1: adding the polymer material into the MOFs solution and stirring to obtain a mixed solution;

[0031] Step 2: Electrospinning the mixed solution obtained in Step 1 under the conditions of a voltage of 15-20kV, a distance of 15-20cm, and a speed of 1-5ml / h to obtain the electrospun material;

[0032] Step 3: Put the electrospun material obtained in Step 2 into a quartz boat, raise the temperature to 700-900° C. under nitrogen protection, and heat-treat for 1-3 hours to obtain a co-doped microsphere-carbon fiber composite material.

[0033] According to the present invention, MOFs solution is prepared first, and described MOFs solution is obtained after dissolving MOFs material in a solvent and carrying out ultrasonic dissolution, and described solvent is preferably dimethylforma...

Embodiment 1

[0040] 1) Disperse 0.1g of zeolite imidazolate skeleton structure (ZIF-67) in 5ml of dimethylformamide (DMF), and sonicate for 1h;

[0041] 2) Weigh 0.3g of PVP and slowly add to the above solution, stir overnight;

[0042] 3) Put the stirred solution into a 5ml disposable syringe, use a 7# stainless steel needle, set a voltage of 16kV, a distance of 16cm, a speed of 5ml / h, and perform electrospinning;

[0043] 4) The above materials were heated in an oven at 150°C for 12 hours, then put into a quartz boat, and the temperature was programmed to rise to 700°C under the protection of nitrogen, and heat treated for 3 hours to obtain the microsphere-carbon fiber composite material.

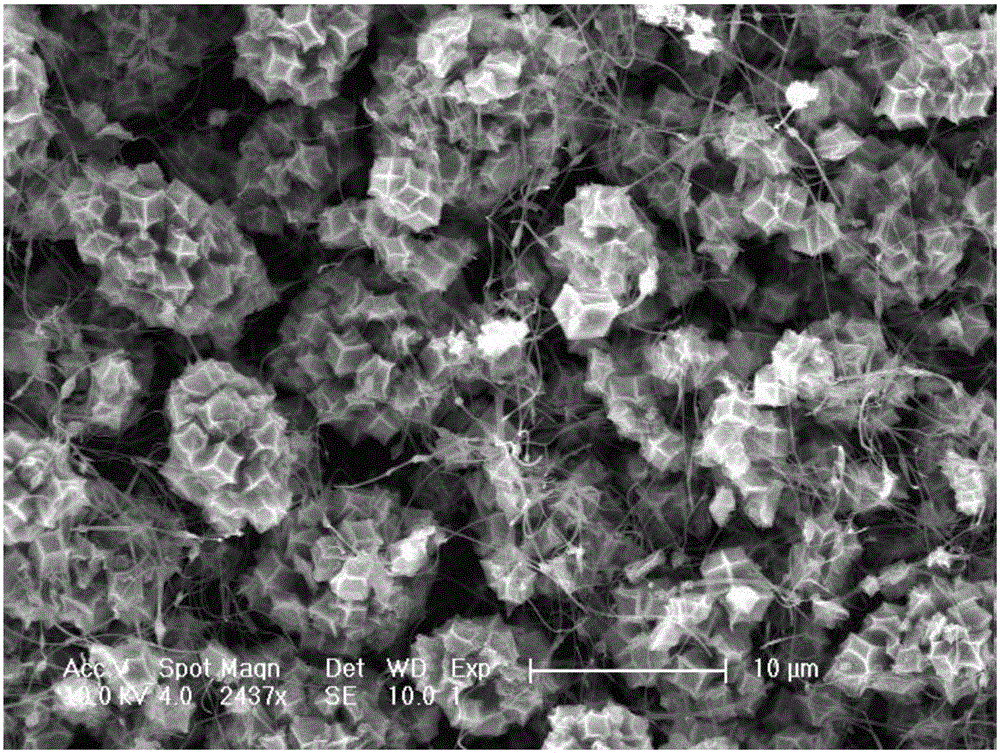

[0044] figure 1 The scanning electron microscope (SEM) figure of the microsphere-carbon fiber composite material prepared for the embodiment of the present invention 1; From figure 1 It can be seen that the composite material with microsphere-carbon fiber structure was successfully prepared in Examp...

Embodiment 2

[0046] 1) Disperse 0.3g of zeolite metal-organic framework material (ZIF-8) in 5ml of DMF, sonicate for 1h;

[0047] 2) Weigh 0.3g of PAN and slowly add to the above solution, and stir overnight;

[0048] 3) Put the stirred solution into a 5ml disposable syringe, use a 7# stainless steel needle, set the voltage to 20kV, the distance is 20cm, and the speed is 2ml / h. perform electrospinning;

[0049]4) The above materials were heated in an oven at 200°C for 12 hours, then put into a quartz boat, and the temperature was programmed to rise to 700°C under the protection of nitrogen, and heat treated for 3 hours to obtain the microsphere-carbon fiber composite material.

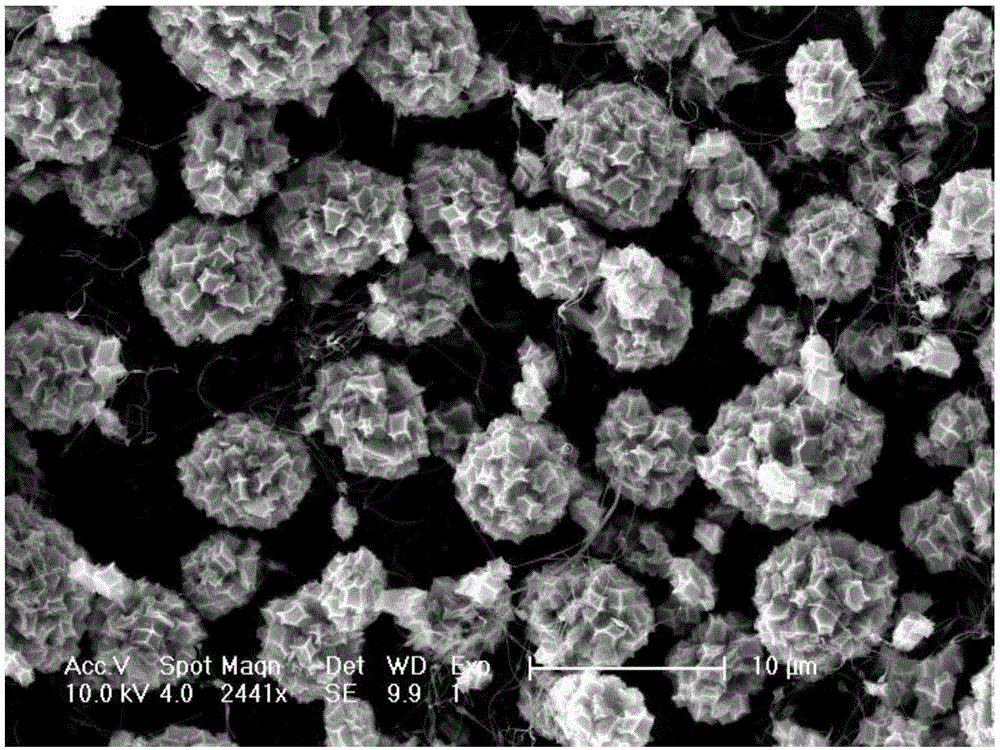

[0050] figure 2 The scanning electron microscope (SEM) picture of the microsphere-carbon fiber composite material prepared for the embodiment of the present invention 2; From figure 2 It can be seen that the composite material with microsphere-carbon fiber structure was successfully prepared in Example 2 of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com