On-line power capacitor operation state monitoring method based on dielectric loss factor

A technology of dielectric loss factor and power capacitor, which is applied in the field of on-line monitoring of substation equipment, can solve problems such as dielectric breakdown discharge, accelerated insulation medium aging, and partial discharge of shells, achieving high reliability and comparability, convenience and safety Effects of operation control and prevention of insulation damage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

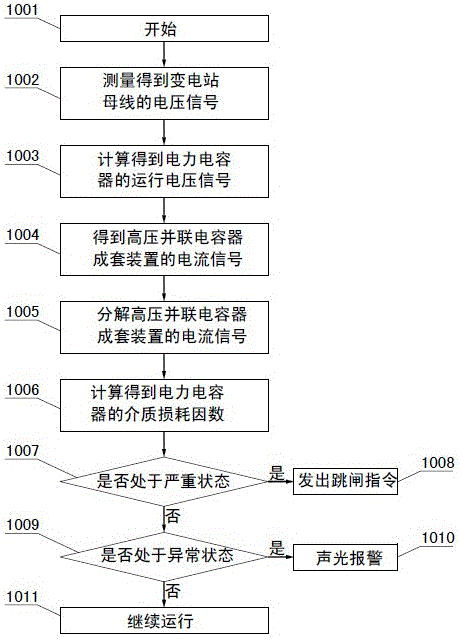

[0031] Figure 1~2 It is the best embodiment of the present invention, below in conjunction with attached Figure 1~2 The present invention will be further described.

[0032] Such as figure 1 As shown, the on-line monitoring method of the power capacitor operating state based on the dielectric loss factor includes the following steps:

[0033] Step 1001, start;

[0034] Started to monitor the operating state of power capacitors based on the dielectric loss factor;

[0035] Step 1002, measuring the voltage signal of the substation bus;

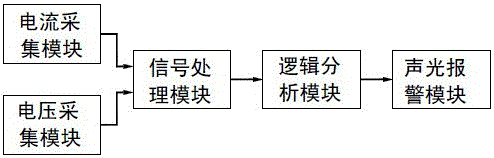

[0036] In the on-line monitoring method for the operating state of the power capacitor based on the dielectric loss factor, a parameter measuring unit for measuring and processing the operating parameters of the high-voltage shunt capacitor complete equipment is provided. Such as figure 2 As shown, the parameter measurement unit includes: a current acquisition module, a voltage acquisition module, a signal processing module, a logic ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com