Preparation method of GaN-based porous DBR

A multi-period, epitaxial structure technology, applied in the field of preparation of GaN-based porous DBR, can solve the problems of complex device process, uneven bottom of epitaxial layer, high cost, high repeatability, simple realization process and controllable reflectivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

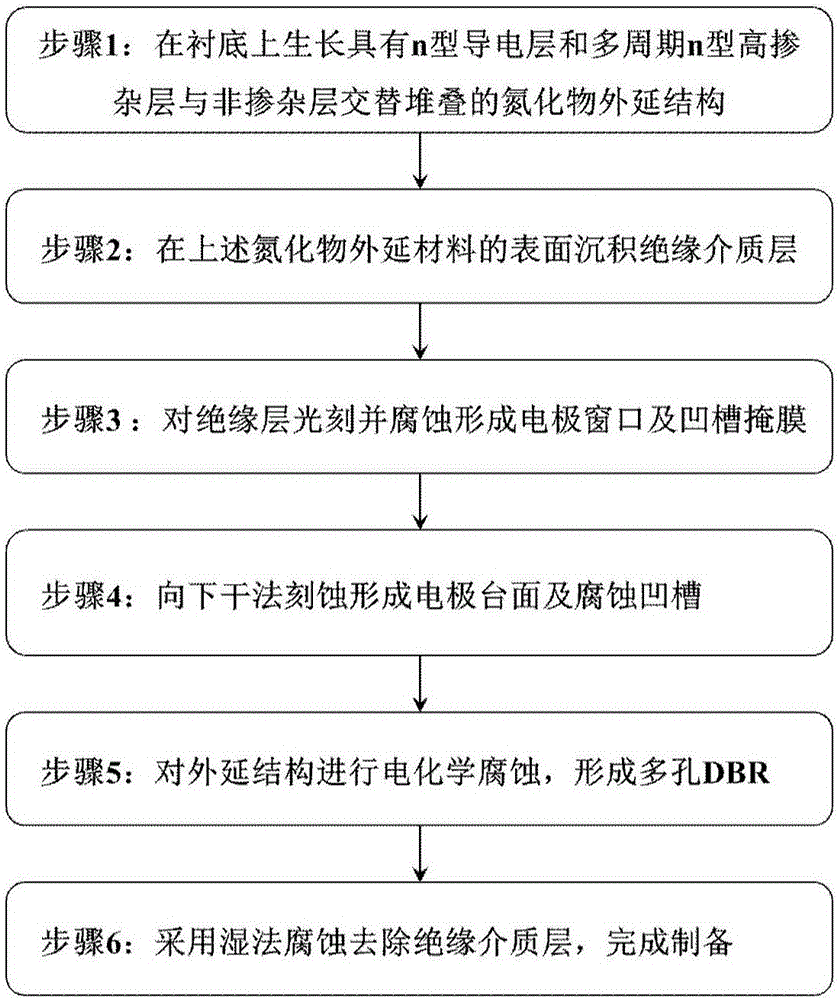

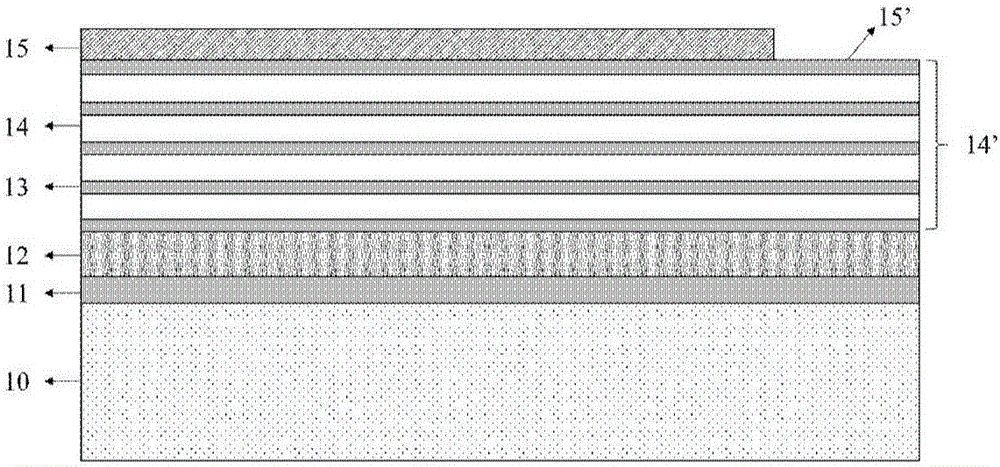

[0019] see figure 1 , and combined with Figure 2-Figure 5 As shown, the present invention provides a method for preparing a GaN-based porous DBR. Including the following steps:

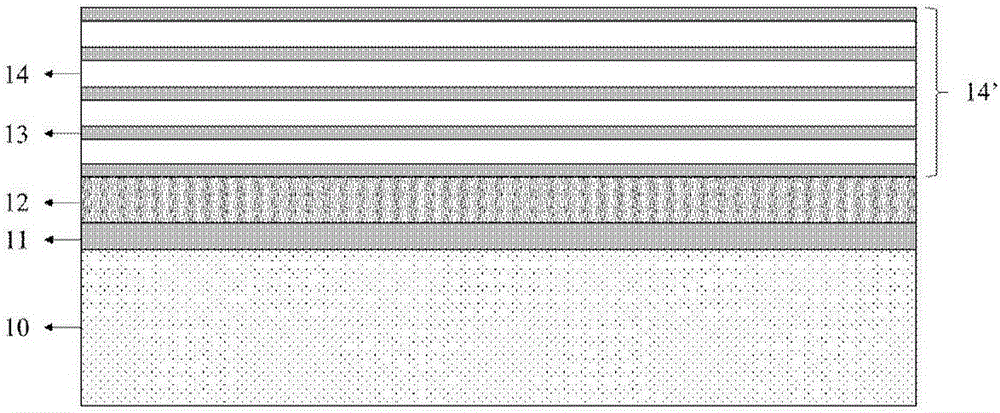

[0020] Step 1: sequentially grow a buffer layer 11, an n-type GaN conductive layer 12, and alternately stacked n-type highly doped layers 13 and non-doped layers 14 on a substrate 10 by metal-organic chemical vapor deposition (MOCVD). Alternately stacked n-type highly doped layers 13 and non-doped layers 14 form a multi-period nitride epitaxial structure 14';

[0021] Wherein the substrate 10 is sapphire, silicon or silicon carbide; the buffer layer 11 is composed of a low-temperature GaN nucleation layer and a non-doped GaN layer grown sequentially, and the materials that can be used as the nucleation layer also include AlN, ZnO or Graphene; the doping concentration of the n-type GaN conductive layer is 5×10 18 cm -3 ;

[0022] The alternately stacked highly doped layers 13 and non-doped layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com