Preparation method of metal film and metal film structure

A metal film and adhesion layer technology, applied in metal material coating process, gaseous chemical plating, coating and other directions, can solve the problems of excessive surface flatness difference, low reflectivity, unstable metal film, etc. Achieve the effect of improving uniformity and consistency, and improving component uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Various embodiments of the invention will be described in more detail below with reference to the accompanying drawings. In the various drawings, the same elements are denoted by the same or similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale.

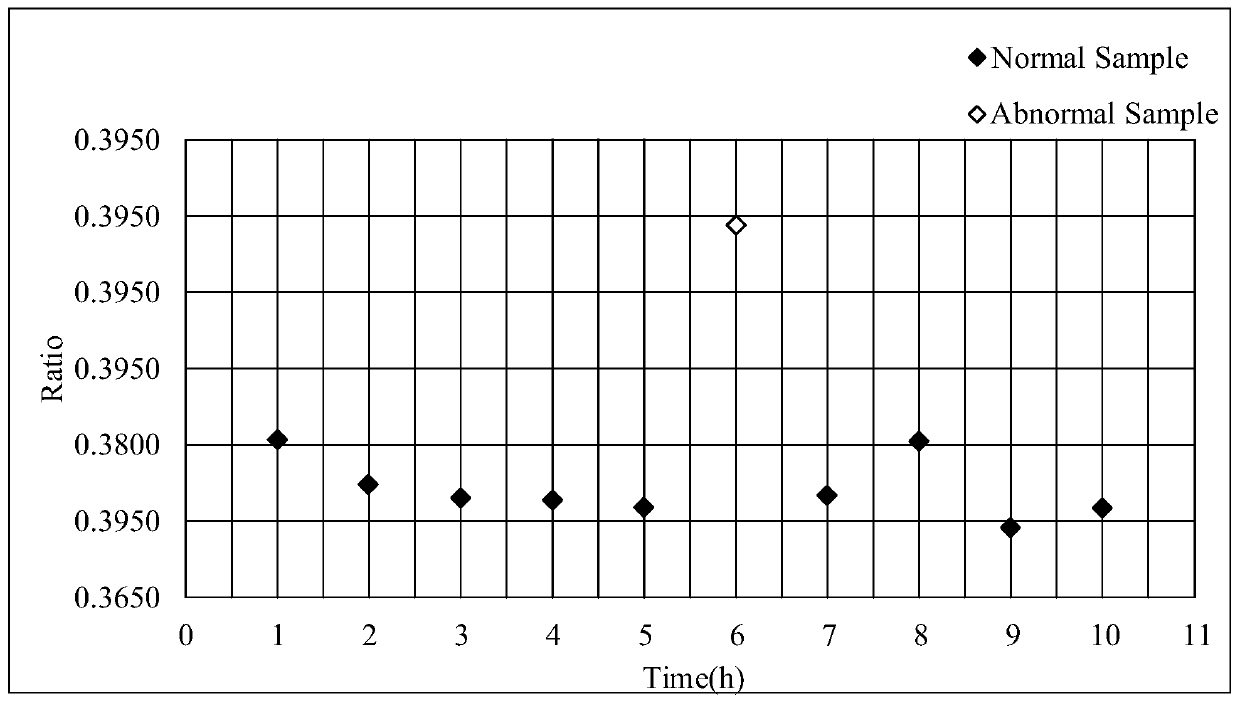

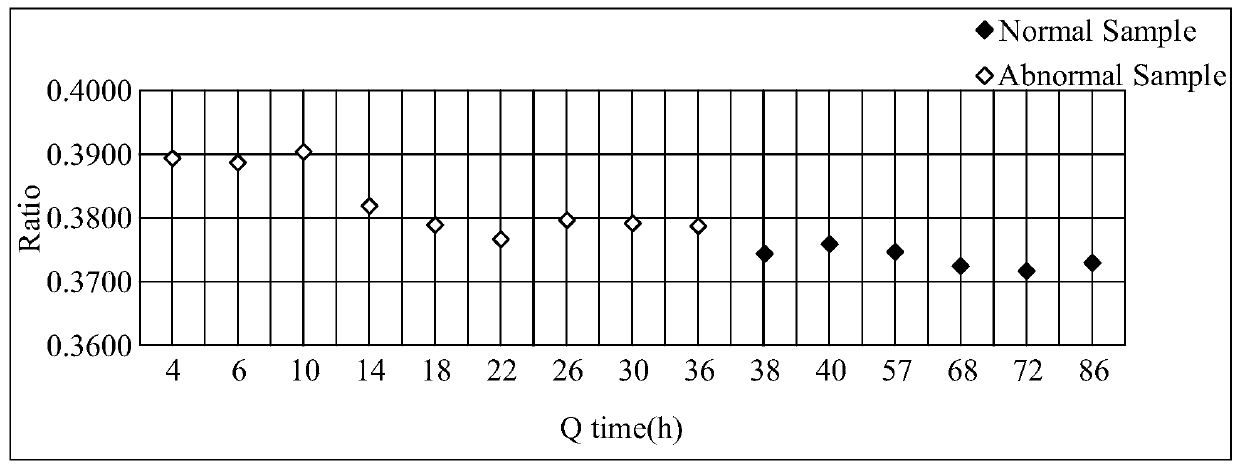

[0028] figure 2 A graph of latency versus reflectivity is shown. exist figure 2 Among them, the abscissa represents the waiting time of the sample from the formation of the adhesion layer to the completion of the growth of the metal film, in hours, and the ordinate represents the reflectivity (ratio), wherein, when the reflectivity of the sample is low, it indicates that its surface flatness is low, when The high reflectivity of the sample indicates its high surface flatness.

[0029] Depend on figure 2 From the variation trend of the middle curve, it can be known that the reflectivity of the sample is related to its waiting time, specifically, the reflectivity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com