Production method of soluble freeze-drying film agent and production thereof

A production method and soluble technology are applied in the field of preparing soluble freeze-dried film preparations, and can solve the problems of garbage formation, waste of raw materials, and retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

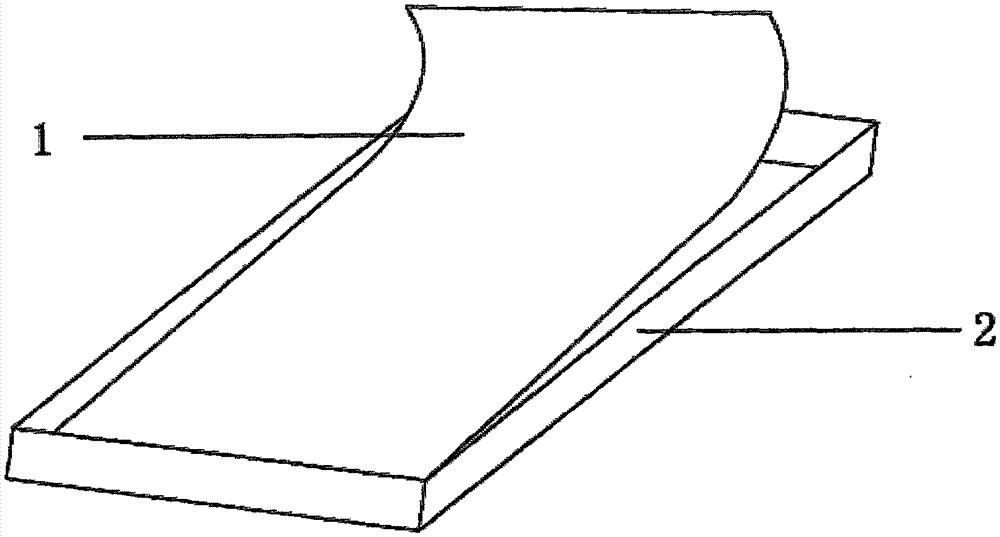

Image

Examples

Embodiment 1

[0059] Collagen, trehalose, carbomer, and triethanolamine are configured into polymers according to a certain ratio, and the ratio is 2500g / m 2 Coating on a flat mold with a coating thickness of 2 mm; then freeze-drying the coated solution and the mold together to obtain a moisturizing skin care film product.

Embodiment 2

[0061] Sodium hyaluronate, pullulan, and mannitol are configured into a polymer solution in a certain proportion, and the concentration is 1200g / m 2 Coat it on a flat mold with a coating thickness of 1 mm; then freeze-dry the coated solution and the mold together, and die-cut according to a certain size to finally obtain a sterile wound antibacterial dressing.

Embodiment 3

[0063] PVA, polyethylene glycol, and glycerin are configured into a polymer solution according to a certain ratio, and Chinese medicine extract is further added according to a ratio of 5%; according to 5000g / m 2 Coating, coating on the grid, a single area of 0.05m 2 In the mold, the coating thickness is 0.5mm; then the coated solution is freeze-dried together with the mold, and finally a soluble film-type drug application product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com