Stable cabazitaxel and albumin composition, and preparation method thereof

A technology of cabazitaxel and albumin, which is applied in the field of stable cabazitaxel albumin aseptic freeze-dried composition and its preparation, can solve problems such as safety, and achieve the goal of reducing production cost, lowering the concentration of use, and excellent stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

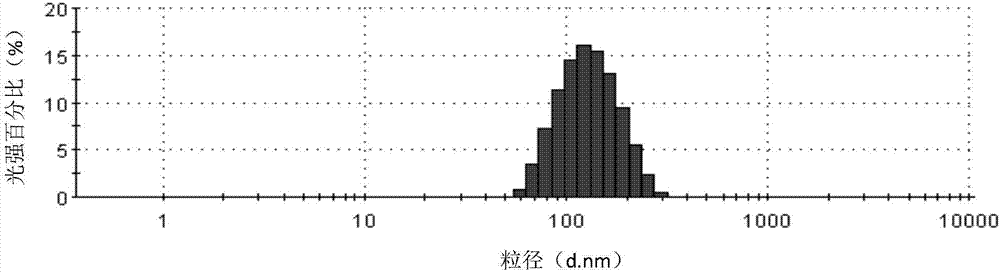

[0070] Dissolve 300mg of Cabazitaxel in 30ml of ethanol to form an organic phase, use 400ml of human serum albumin aqueous solution (15mg / ml) as the water phase, mix the water phase with the organic phase, place in a high-speed shearing machine at 10000rpm After shearing at a certain speed, transfer it to a high-pressure homogenizer, homogenize under a pressure of 35,000 psi, and circulate for 5 times to prepare a suspension with an average particle size of 119.8nm and a pH of 6.7. Pass the suspension through Filter and sterilize with a 0.22 μm sterile filter head, and directly freeze-dry for 60 hours to obtain a freeze-dried composition. After the freeze-drying is completed, the composition is reconstituted with physiological saline, and the measured zeta potential is -5.7mv. Particle size analysis was carried out using a Malvern particle size analyzer, and the measured average particle size was 120.3nm. After standing at room temperature, it was detected by high-performance l...

Embodiment 2

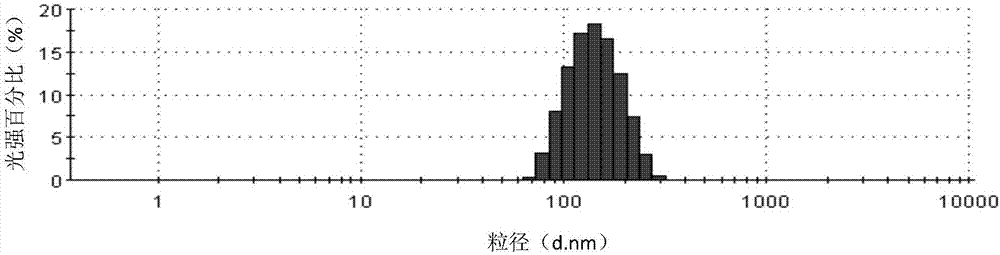

[0072] Dissolve 300mg of Cabazitaxel in 15ml of ethanol to form an organic phase, use 500ml of human serum albumin aqueous solution (6mg / ml) as the water phase, mix the water phase with the organic phase, place in a high-speed shearing machine at 7000rpm After shearing at a certain speed, transfer it to a high-pressure homogenizer, perform homogenization under a pressure of 30,000 psi, and circulate for 5 times to prepare a suspension with an average particle size of 134.4nm and a pH of 6.5. Pass the suspension through Filter and sterilize with a 0.22 μm sterile filter head, and directly freeze-dry for 60 hours to obtain a freeze-dried composition. After the freeze-drying is completed, the composition is reconstituted with physiological saline, and the measured zeta potential is -3.4mv. Particle size analysis was carried out using a Malvern particle size analyzer, and the measured average particle size was 135.4nm. After being placed at room temperature, it was detected by HPLC...

Embodiment 3

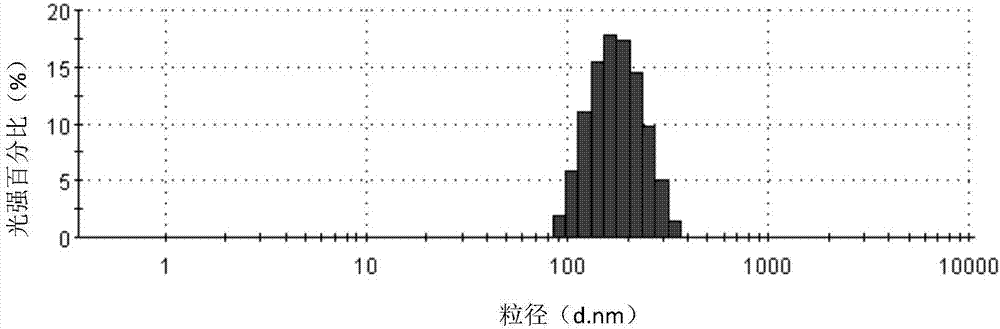

[0074] Dissolve 300 mg of Cabazitaxel in 10 ml of ethanol to form an organic phase, use 180 ml of human serum albumin aqueous solution (20 mg / ml) as the water phase, mix the water phase with the organic phase, and place in a high-speed shearing machine at 15000 rpm After shearing at a certain speed, transfer it to a high-pressure homogenizer, homogenize under a pressure of 40,000 psi, and circulate 6 times to prepare a suspension with an average particle size of 164.4nm and a pH of 7.0. Pass the suspension through Filter and sterilize with a 0.22 μm sterile filter head, and directly freeze-dry for 60 hours to obtain a freeze-dried composition. After the freeze-drying is completed, the composition is reconstituted with physiological saline, and the measured zeta potential is -7.5mv. Particle size analysis was carried out using a Malvern particle size analyzer, and the measured average particle size was 165.7nm. After being placed at room temperature, it was detected by HPLC that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com