Production method and product of novel multiwalled carbon nanotube-dopamine-polyethyleneglycol diacrylate hydrogel film

A technology of polyethylene glycol diacrylate and multi-walled carbon nanotubes, applied in the field of biomedicine, can solve the problems of poor mechanical properties of natural materials, lack of receptors for cell recognition, etc., and achieve strong operability and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

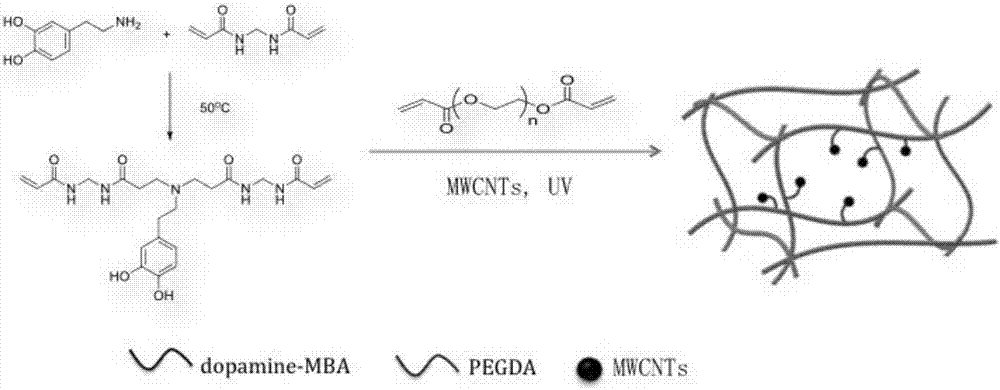

[0027] Preparation of multi-walled carbon nanotube-dopamine-polyethylene glycol diacrylate hydrogel film, the specific steps are as follows:

[0028] (1) Add N,N-methylenebisacryloylamine (MBA) into the ethanol solution to obtain the MBA solution, wherein the pH value of the ethanol solution is 6, and the volume ratio of water to ethanol in the ethanol solution is 4 : 3, MBA concentration is 70.1mg / ml in the MBA solution that makes;

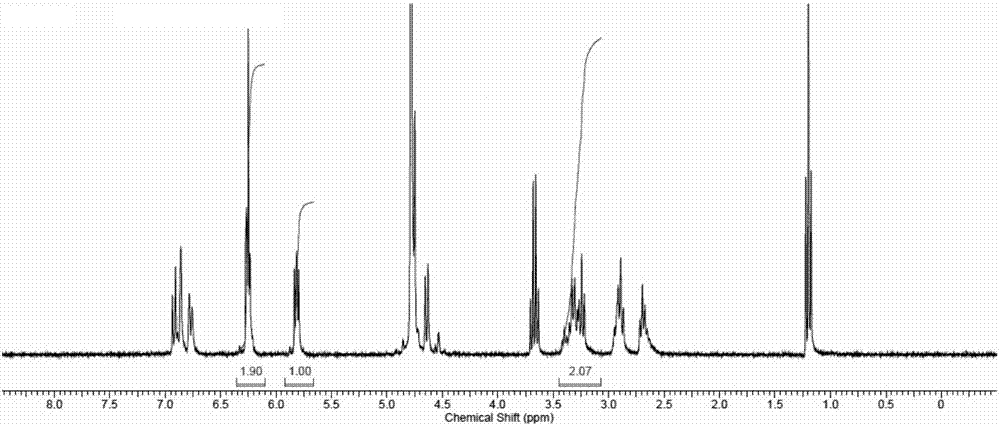

[0029] (2) Add dopamine to the MBA solution prepared in step (1) under nitrogen protection according to the molar ratio of dopamine to MBA in the MBA solution of 2:3, stir at 45°C in the dark for 3 days, and freeze-dry to prepare dopamine-MBA Cross-linking agent, the prepared dopamine-MBA cross-linking agent is stored at 20°C; 1 H NMR nuclear magnetic resonance spectroscopy identifies the chemical structure of the dopamine-MBA crosslinker, the results are as follows figure 1 shown by figure 1 It can be seen that 5.7 and 6.2 ppm represent vinyl...

Embodiment 2

[0034] Preparation of multi-walled carbon nanotube-dopamine-polyethylene glycol diacrylate hydrogel film, the specific steps are as follows:

[0035] (1) Add N,N-methylenebisacryloylamine (MBA) into the ethanol solution to obtain the MBA solution, wherein the pH value of the ethanol solution is 6, and the volume ratio of water to ethanol in the ethanol solution is 4 : 3, MBA concentration is 70.1mg / ml in the MBA solution that makes;

[0036] (2) Add dopamine to the MBA solution prepared in step (1) under the protection of nitrogen according to the molar ratio of dopamine to MBA in the MBA solution of 2:3, stir at 50°C in the dark for 2 days, and freeze-dry to prepare dopamine-MBA Cross-linking agent, store the prepared dopamine-MBA cross-linking agent at 20°C;

[0037] (3) adding multi-walled carbon nanotubes into a poloxamer solution (F127 solution) with a mass volume percentage of 10% to prepare a multi-walled carbon nanotube solution, the multi-walled carbon nanotubes in t...

Embodiment 3

[0041] Preparation of multi-walled carbon nanotube-dopamine-polyethylene glycol diacrylate hydrogel film, the specific steps are as follows:

[0042] (1) Add N,N-methylenebisacryloylamine (MBA) into the ethanol solution to obtain the MBA solution, wherein the pH value of the ethanol solution is 6, and the volume ratio of water to ethanol in the ethanol solution is 4 : 3, MBA concentration is 70.1mg / ml in the MBA solution that makes;

[0043] (2) Add dopamine to the MBA solution prepared in step (1) under the protection of nitrogen according to the molar ratio of dopamine to MBA in the MBA solution of 2:3, stir at 55°C in the dark for 1 day, and freeze-dry to prepare dopamine-MBA Cross-linking agent, store the prepared dopamine-MBA cross-linking agent at 20°C;

[0044](3) adding multi-walled carbon nanotubes into a poloxamer solution (F127 solution) with a mass volume percentage of 10% to make a multi-walled carbon nanotube solution, the multi-walled carbon nanotubes in the mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com