Giant lotus root corn noodle and making method thereof

A technology of lotus root and lotus root, which is applied in the field of lotus root corn noodles and its preparation, can solve the problems of insufficient utilization of lotus root, corn can not be used as staple food, and bad taste, so as to protect the gastrointestinal tract and have a delicate taste , the effect of maintaining blood pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

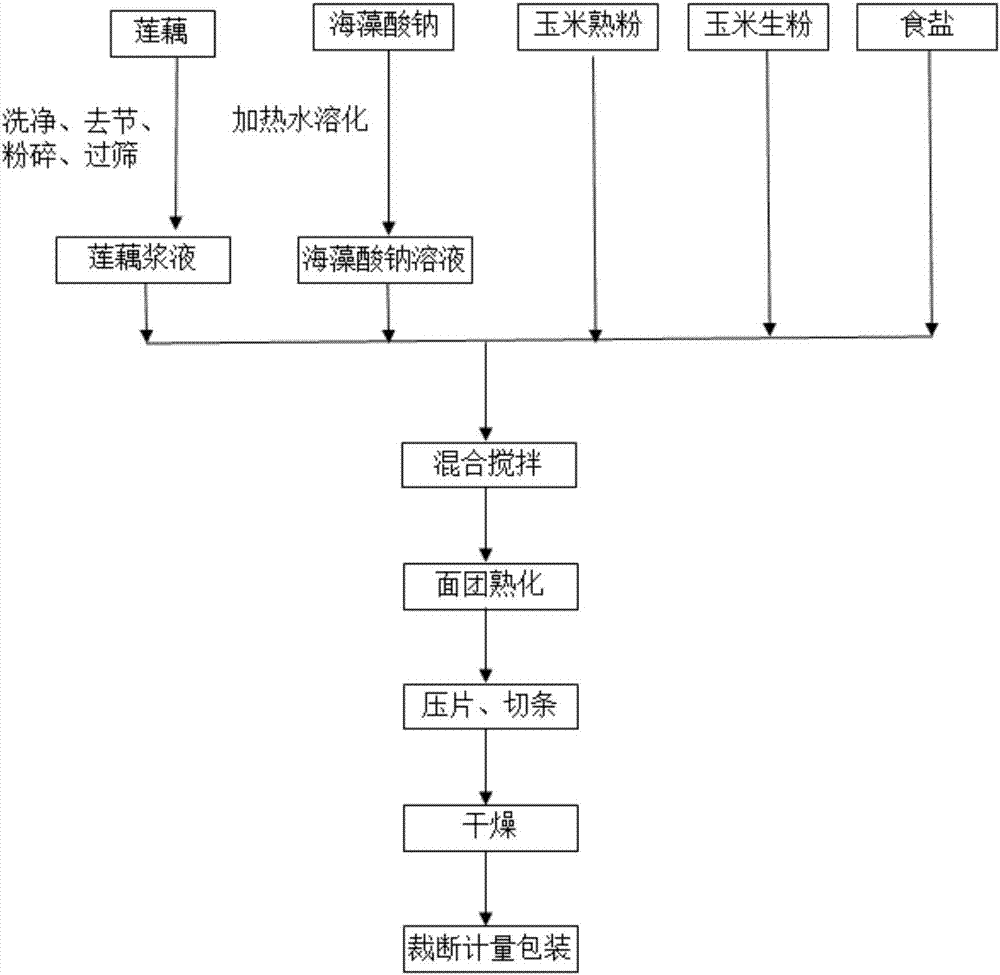

[0037] Preparation of Huaqilian corn noodles

[0038] Preparation of Huaqi lotus root slurry: After washing, removing knots and dicing the Huaqi lotus root, crush it with a potato grinder and pass through a 100-mesh sieve to obtain the Huaqi lotus root slurry, refrigerate it, and set aside. The obtained slurry is 90% of the total weight of Huaqi lotus root, and the residue is 10% of the total weight of Huaqi lotus root.

[0039] Ingredients: Take 50kg of corn flour with 120 mesh, 40kg of cooked corn flour with 120 mesh, 0.5kg of sodium alginate, 1kg of salt, and 35kg of Huaqi lotus root slurry.

[0040] Stirring: After adding 0.5kg of sodium alginate to 1.5kg of hot water at 60℃ to dissolve, put the sodium alginate solution, corn starch, corn cooked powder, and salt in a dough mixer and stir evenly, then add Huaqi lotus root slurry and stir. , The stirring temperature is 35℃, and the stirring time is 25min.

[0041] Maturation: After the mixing is completed, the dough obtained by mix...

Embodiment 2

[0046] Preparation of Huaqilian corn noodles

[0047] Preparation of Huaqi lotus root slurry: After washing, removing knots and dicing the Huaqi lotus root, crush it with a potato grinder, pass through an 80-mesh sieve, and obtain the Huaqi lotus root slurry, refrigerate and set aside. The obtained slurry is 88% of the total weight of Huaqi lotus root, and the residue is 12% of the total weight of Huaqi lotus root.

[0048] Ingredients: 45kg of corn flour of 120 mesh, 35kg of cooked corn flour, 0.2kg of sodium alginate, 1.5kg of salt, and 40kg of Huaqilian lotus root slurry.

[0049] Stirring: Add 0.2kg of sodium alginate to 1.5kg of hot water at 60℃ to dissolve, dissolve 1.5kg of salt with 5kg of water, and place the sodium alginate solution, salt solution, corn starch, corn cooked powder, and lotus root slurry Stir evenly in the dough mixer, the stirring temperature is 28℃, and the stirring time is 20min.

[0050] Maturation: After the mixing is completed, put the dough obtained by...

Embodiment 3

[0055] Preparation of Huaqilian corn noodles

[0056] Preparation of Huaqi lotus root slurry: After washing, removing knots and dicing the Huaqi lotus root, crush it with a potato grinder and pass through a 100-mesh sieve to obtain the Huaqi lotus root slurry, refrigerate it, and set aside. The obtained slurry is 85% of the total weight of Huaqi lotus root, and the residue is 15% of the total weight of Huaqi lotus root.

[0057] Ingredients: Take 48 kg of corn flour with 120 mesh, 37 kg of cooked corn flour with 120 mesh, 0.3 kg of sodium alginate, 1 kg of salt, and 40 kg of Huaqi lotus root slurry.

[0058] Stirring: After adding 0.3kg of sodium alginate to 1.5kg of hot water at 60℃ to dissolve it, put the sodium alginate solution, corn starch, corn cooked powder, and salt in a dough mixer and stir evenly, then add Huaqi lotus root slurry and stir. , The stirring temperature is 30℃, and the stirring time is 25min.

[0059] Maturation: After the mixing is completed, the dough obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com