Combined atomization type device and method for preparing spherical metal alloy micro powder

A technology of metal alloy and micropowder, which is applied in the field of 3D printing, can solve the problems of high cost, irregular shape of micropowder, and increased difficulty, and achieve the effect of improving sphericity, particle size controllability, and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

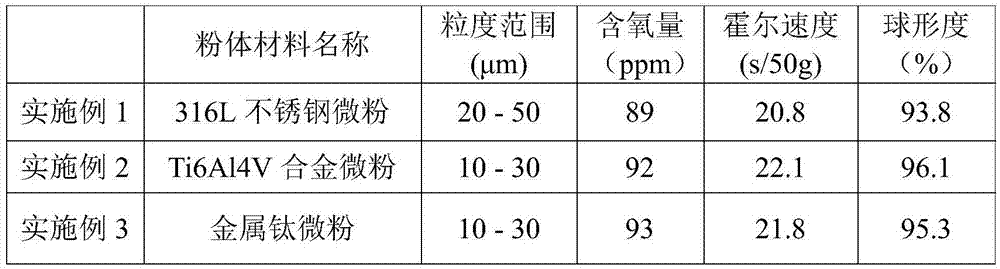

[0079] The production of spherical 316L stainless steel powder suitable for 3D printing.

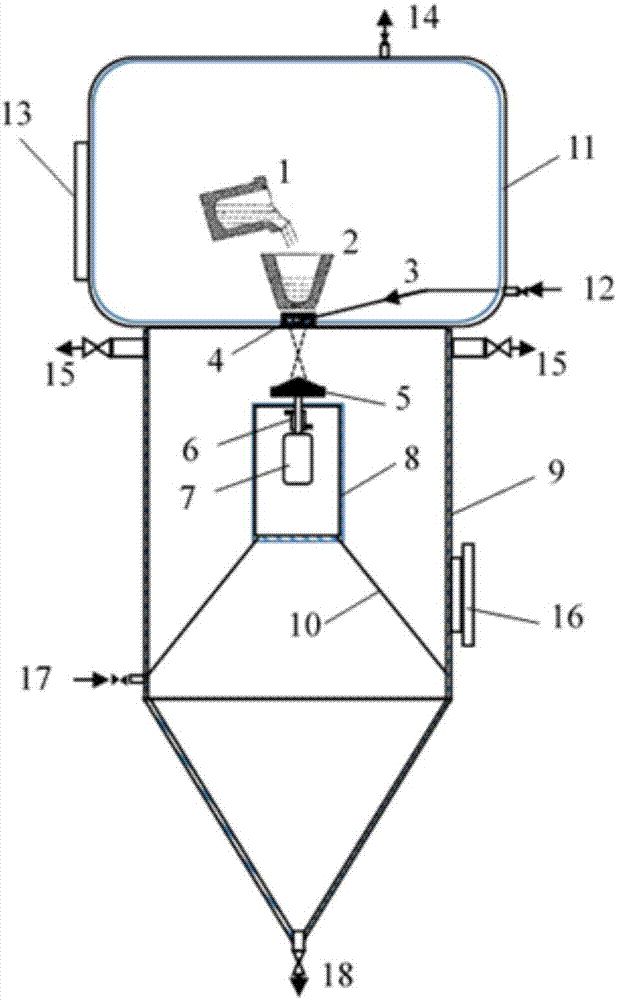

[0080] The inner diameter of the shell (9) of the atomization chamber is 5.5m, the height of the straight section is 4.0m, the capacity of the induction melting furnace (1) is 30kg, the diameter of the leakage hole of the gas atomization spray ring (4) is 5mm, and the spray top angle is 40°, select a conical centrifugal atomization turntable (5) with a diameter of 100mm, the apex angle of the conical surface is 140°, the intersection of the upper end surface of the centrifugal atomization turntable (5) and the sprayed gas from the gas atomization spray ring (4) The distance between the points is 30mm, and the rotating speed of the high-speed motor (7) is set at 6000rpm.

[0081] Select 30kg of 316L grade stainless steel raw material with an oxygen content lower than 200ppm (mass), first wash with water and perform ultrasonic cleaning to remove impurities on the surface of the raw materia...

Embodiment 2

[0086] Production of spherical Ti6Al4V alloy powders suitable for 3D printing.

[0087] The inner diameter of the shell (9) of the atomization chamber is 6.0m, the height of the straight section is 5.0m, the capacity of the induction melting furnace (1) is 30kg, the diameter of the leakage hole of the gas atomization spray ring (4) is 6mm, and the spray top angle is 45°, choose a conical centrifugal atomization turntable (5) with a diameter of 120mm, the apex angle of the cone surface is 120°, the upper end surface of the centrifugal atomization turntable (5) meets the gas sprayed by the gas atomization spray ring (4) The distance between the points is 40mm, and the rotating speed of the high-speed motor (7) is set at 10000rpm.

[0088] Select 30 kg of Ti6Al4V alloy raw material with an oxygen content lower than 200ppm (mass), first wash with water and perform ultrasonic cleaning to remove impurities on the surface of the raw material, and obtain the metal alloy raw material to ...

Embodiment 3

[0093] Production of spherical titanium metal powder suitable for 3D printing.

[0094] The inner diameter of the shell (9) of the atomization chamber is 7.0m, the height of the straight section is 5.5m, the capacity of the induction melting furnace (1) is 30kg, the leak hole diameter of the gas atomization spray ring (4) is 6.5mm, and the spray top angle is 50°, choose a conical surface centrifugal atomization turntable (5) with a diameter of 130mm, the apex angle of the cone surface is 130°, and the upper end surface of the centrifugal atomization turntable (5) is connected with the gas spray ring (4) The distance between the meeting points is 50mm, and the rotating speed of the high-speed motor (7) is set at 8000rpm.

[0095] Select 30kg of metal titanium raw material with an oxygen content lower than 100ppm (mass), first wash with water and perform ultrasonic cleaning to remove impurities on the surface of the raw material, and obtain the metal alloy raw material to be mel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com