A process of reinforcing the denitrification efficiency of an anaerobic ammoxidation reactor by utilizing a spongy iron filler

A technology of anaerobic ammonium oxidation and sponge iron, applied in the direction of anaerobic digestion treatment, chemical instruments and methods, water pollutants, etc., to achieve the effect of simple operation process, full degradation, and promotion of bacterial growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

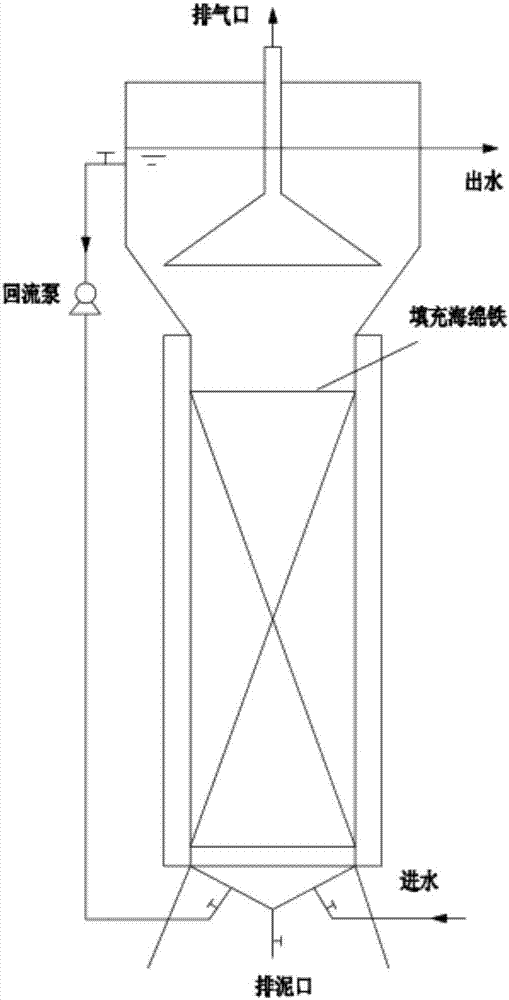

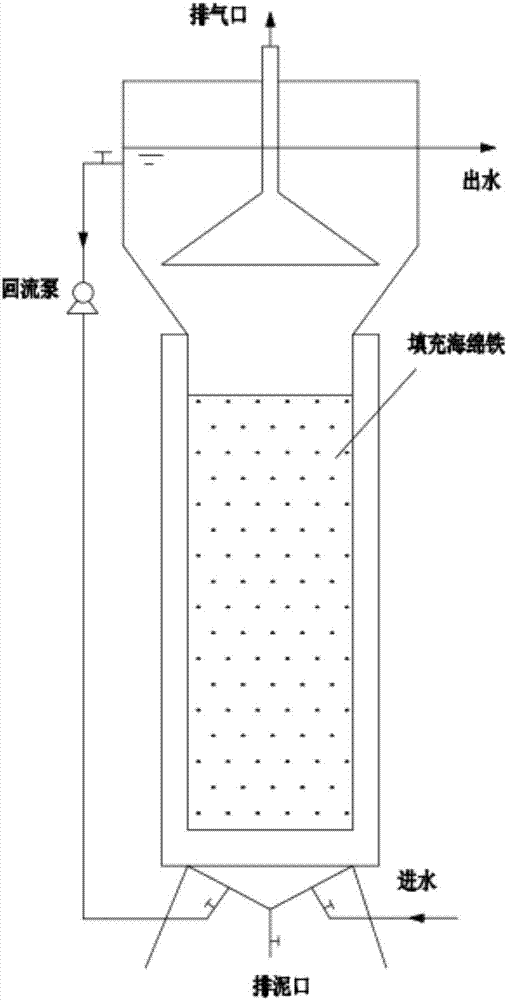

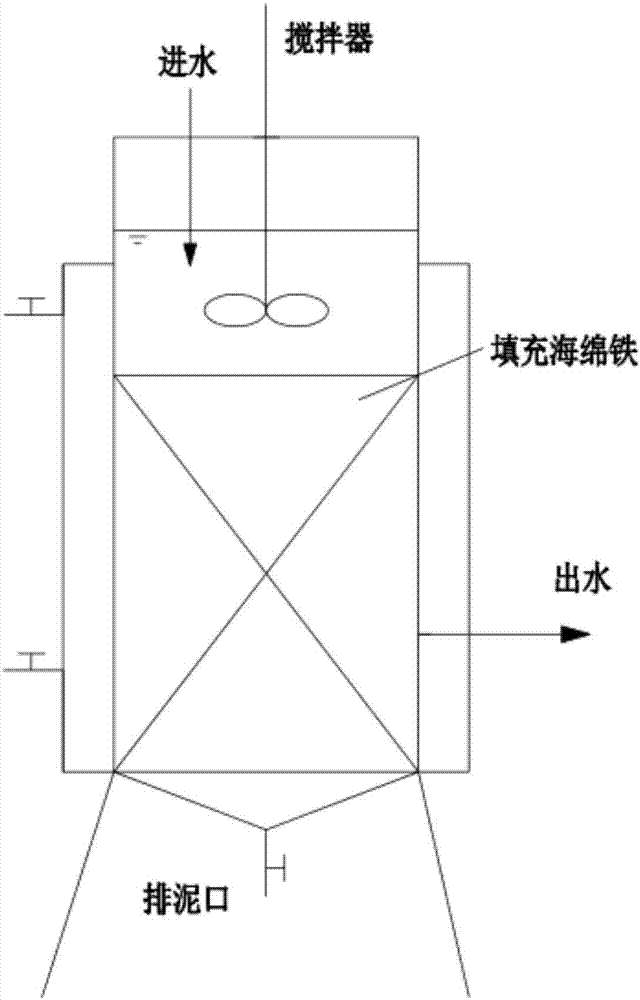

[0014] The process for strengthening the denitrification efficiency of anaerobic ammonium oxidation reactor with sponge iron filler of the present invention includes the following: the filler added to the anaerobic ammonium oxidation reactor is sponge iron with a particle size of 0.1-8mm and 30g-100g / L , improve the efficiency of anaerobic ammonium oxidation denitrification; sponge iron removes dissolved oxygen or / and oxidative substances brought in raw water through reduction, and is conducive to the conversion and removal of ammonia nitrogen, nitrite nitrogen and nitrate nitrogen, eliminating The inhibitory effect of dissolved oxygen and oxidizing substances on anammox bacteria; the divalent ferrous ions and ferric ions dissolved from the sponge iron can be used as trace elements to supply microorganisms to promote the physiological and biochemical reactions of microorganisms. The growth of ammonia oxidizing bacteria provides the necessary conditions, and at the same time, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com