Preparation method of plantpolyenoidbisphenolfriction powder

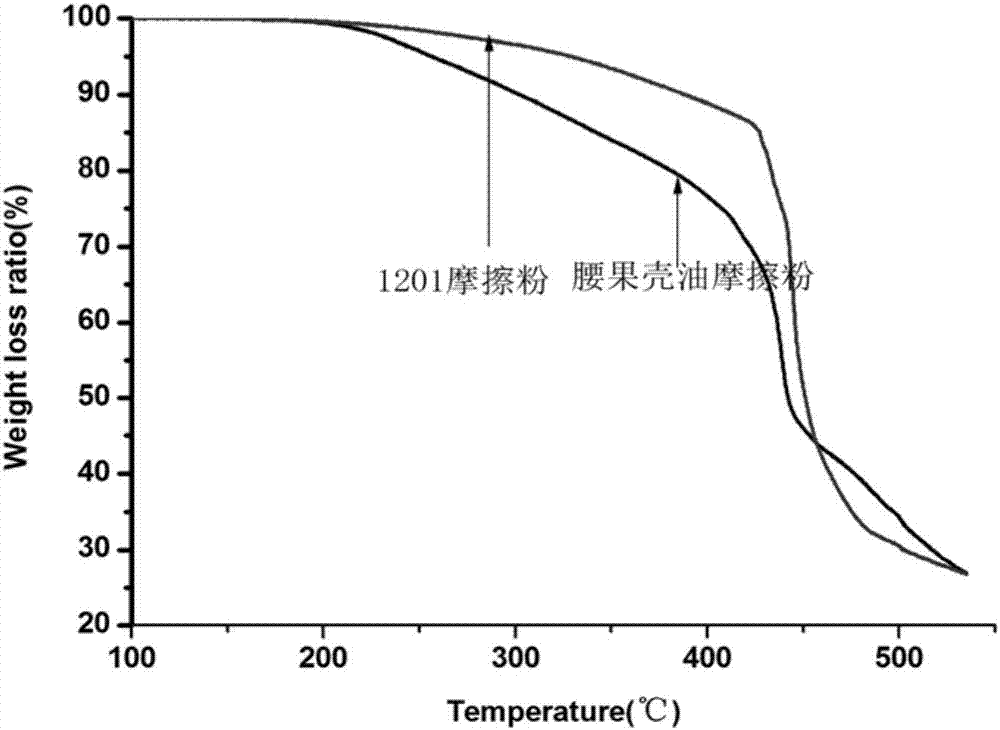

A technology of ethylene bisphenol friction powder and ethylene bisphenol, which is applied in the field of plant polyene bisphenol friction powder and its preparation, and can solve problems such as insufficient heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

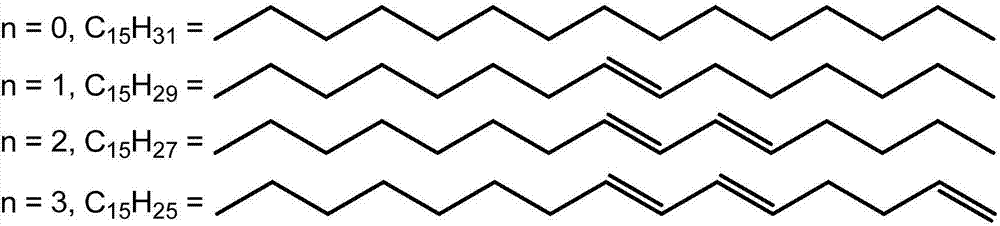

Method used

Image

Examples

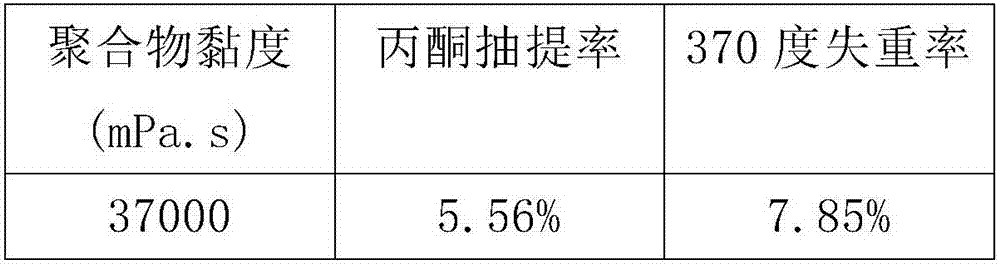

Embodiment 1

[0026] Add plant polyene bisphenol into the reaction kettle, add 3% sulfuric acid and 3% urotropine accounting for plant polyene bisphenol, polymerize at 100 degrees for 4 hours, test the viscosity of the prepolymer after polymerization, add 8% urotropine The product was added to the prepolymer, cured at 135°C for 4 hours, and cured at 175°C for 3 hours. The acetone extraction rate and the index of weight loss at 370°C were tested. The results are shown in Table 1.

[0027] Table 1

[0028]

Embodiment 2

[0030] Add plant polyene bisphenol into the reaction kettle, add 3% sulfuric acid and 3% urotropine accounting for plant polyene bisphenol, polymerize at 100 degrees for 4 hours, test the viscosity of the prepolymer after polymerization, add 10.65% paraformaldehyde Add it to the prepolymer, cure at 135°C for 4 hours, and cure at 175°C for 3 hours. Test the acetone extraction rate and the index of weight loss at 370°C. The results are shown in Table 2.

[0031] Table 2

[0032]

Embodiment 3

[0034] Add plant polyene bisphenol into the reaction kettle, add 3% sulfuric acid and 3% urotropine accounting for plant polyene bisphenol, polymerize at 100 degrees for 4 hours, test the viscosity of the prepolymer after polymerization, add 33% furfural to the prepolymer In the polymer, it was cured at 135°C for 4 hours, and at 175°C for 3 hours. The acetone extraction rate and the index of weight loss at 370°C were tested. The results are shown in Table 3.

[0035] table 3

[0036]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap