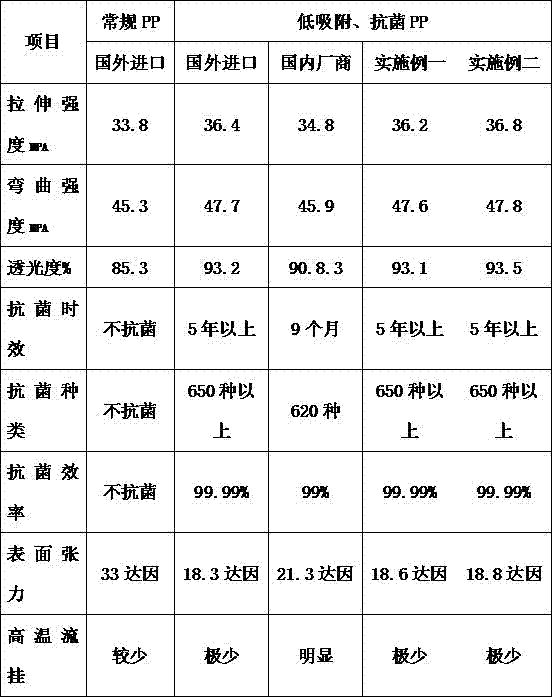

Transparent PP biomaterial with low-adsorption, high-temperature anti-sagging and antibacterial performance and preparation method thereof

A biological material and anti-sagging technology, which is applied in the field of biological materials, can solve the problems of added material precipitation, quality deficiency, film-like residue, etc., and achieve the effects of preventing precipitation and floating color, enhancing antibacterial effect, and low surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] (1) With condensed water in the barrel wall of the high-speed mixing cylinder, set the temperature of the barrel below 30 degrees Celsius.

[0015] (2) Add 97 parts of polypropylene into the barrel, add 0.5 parts of polyether-modified polydimethylsiloxane and 0.2 parts of dipropylene glycol monomethyl ether into the polypropylene, and stir for 1-2 minutes.

[0016] (3) Then add 0.7 part of sorbitol transparent nucleating agent, 0.1 part of antioxidant and 0.08 part of processing aid into the barrel, and stir for 1-2 minutes; while stirring, drop 0.3 part into the barrel High temperature anti-sagging agent and 0.002 nanometer silver solution.

[0017] (4) Extrude the stirred PP biomaterial with co-rotating parallel twin-screws, set the host speed of co-rotating parallel twin-screws at 380 rpm;

[0018] (5) Cut the extruded PP biomaterial into 3*3mm pellets with a gantry pelletizer, and cool the material while cutting. The cooling methods include air cooling and water co...

Embodiment 2

[0021] (1) With condensed water in the barrel wall of the high-speed mixing cylinder, set the temperature of the barrel below 30 degrees Celsius.

[0022] (2) Add 99 parts of polypropylene into the barrel, add 0.8 parts of polyether-modified polydimethylsiloxane and 0.4 parts of dipropylene glycol monomethyl ether into the polypropylene, and stir for 1-2 minutes.

[0023] (3) Then add 0.8 parts of sorbitol transparent nucleating agent, 0.25 parts of antioxidant and 0.15 parts of processing aid into the barrel, and stir for 1-2 minutes; while stirring, drop 0.9 parts into the barrel High temperature anti-sagging agent and 0.004 nanometer silver solution.

[0024] (4) Extrude the stirred PP biomaterial with co-rotating parallel twin-screws, set the host speed of co-rotating parallel twin-screws at 500 rpm;

[0025] (5) Cut the extruded PP biomaterial into 3*3mm pellets with a gantry pelletizer, and cool the material while cutting. The cooling methods include air cooling and wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com