Method for preparing yellow rice wine by adopting mixed raw materials and prepared yellow rice wine

A production method and rice wine technology, which is applied in the field of rice wine processing, can solve the problems of insufficient growth of acid-producing bacteria, insufficient use of raw materials, and insufficient use of starch, etc., to achieve rich wine body components, sufficient nutrition for yeast reproduction, and good taste rich effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

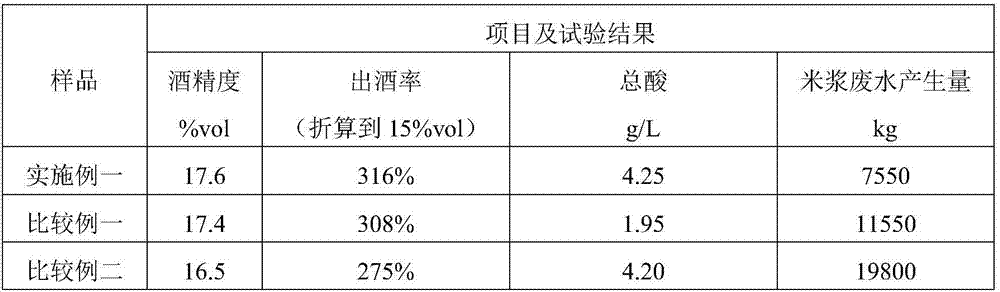

Examples

Embodiment 1

[0032] (1) Soak rice: select 10500 kg of mildew-free rice, sieve out broken rice, soil and sand, and remove impurities. With 11550kg water (1.1 times of rice weight) rice is soaked 30 hours, soak rice water temperature is 15 ℃;

[0033] (2) Cooking rice: steam the soaked rice with steam, the steam pressure is 0.30MPa, and the cooking time is 55min.

[0034] (3) Corn starch liquefaction and saccharification: corn starch gelatinization is carried out in the gelatinization pot, and the process is as follows:

[0035] Pump 16,000kg of water into the gelatinization tank with a water temperature of 40°C.

[0036] Feed 7500kg of cornstarch, turn on the mixer and compressed air, add 1kg of temperature-resistant α-amylase, and heat the cornstarch with steam through the direct firing tube and coiled intestine tube.

[0037] When the product temperature reaches 62°C, add 2.5kg of temperature-resistant α-amylase for the second time; when the product temperature rises to 66°C, add 1kg of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com