Isolation type high-frequency low-loss driving circuit

A drive circuit, isolated technology, applied in the field of isolated drive circuit, can solve the problems that it is difficult to control the gate voltage amplitude of the switch tube M, affect the circuit efficiency, and the work of the switch tube, so as to improve the energy conversion efficiency and reduce the cycle Energy, the effect of reducing amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

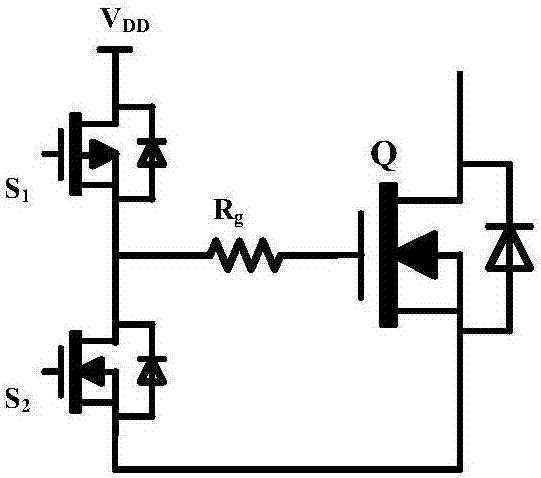

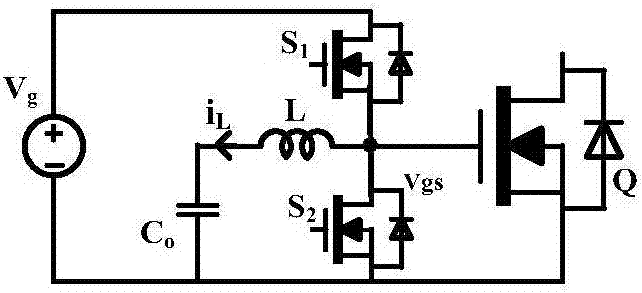

[0085] Embodiment 1: A class of full-bridge isolated drive circuit, the square wave power supply is realized through the full-bridge topology, and its circuit structure is as follows Figure 18 , Figure 19 , Figure 20 , Figure 21 , Figure 22 , Figure 23 and Figure 24 shown.

[0086] The specific connection method is: the input voltage source (Vin) is connected in parallel with the two bridge arms; the resonant inductance (L r ), DC blocking capacitor (C B ) and the primary winding are connected in series in a branch, and the two ends of the branch are respectively connected to the midpoint of the two bridge arms. Such as Figure 18 As shown, the first secondary winding of the transformer (T 1b ) to one end of the switch tube (M 1 ) gate, and the other end of the first secondary winding of the transformer is connected to the switch tube (M 1 ) source.

[0087] Such as Figure 19 As shown, the first secondary winding (T 1b ) is connected to the first switch t...

Embodiment 2

[0095] Embodiment 2: A class of half-bridge isolated drive circuit, the square wave power supply is realized by half-bridge (Type A) topology, and its circuit structure is as follows Figure 27 , Figure 28 , Figure 29 , Figure 30 and Figure 31 shown.

[0096] The specific connection method is: input voltage source (V in ) with the switch arm and two input capacitors (C in1 ), (C in2 ) The bridge arms composed of ) are connected in parallel, and the resonant inductance (L r ) is connected in series with the primary winding in a branch, and the two ends of the branch are respectively connected to the midpoint of the two bridge arms. Such as Figure 27 As shown, the first secondary winding of the transformer (T 1b ) to one end of the switch tube (M 1 ) gate, and the other end of the first secondary winding of the transformer is connected to the switch tube (M 1 ) source.

[0097] Such as Figure 28 As shown, the first secondary winding (T 1b ) is connected to th...

Embodiment 3

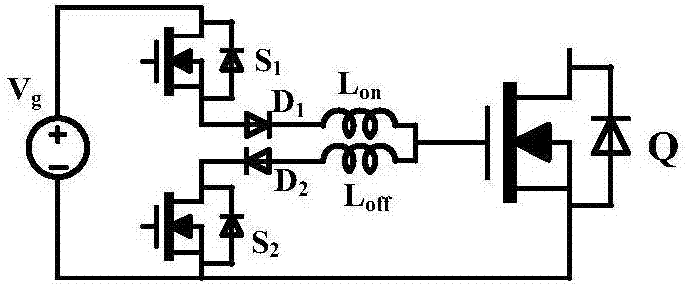

[0101] Embodiment 3: A class of push-pull isolated drive circuit, the square wave power supply is realized by push-pull topology, and its circuit structure is as follows Figure 32 shown.

[0102] The specific connection method is: input voltage source (V in ) negative pole and switch tube (S 1 ), (S 2 ) connected to the source, the input voltage source (V in ) positive pole and transformer (T 1 ) first primary winding (T 1a1 ) terminal with the same name, the second primary winding of the transformer (T 1a2 ) connected to the opposite end, the first primary winding of the transformer (T 1a1 ) and the switch tube (S 1 ) is connected to the drain, and the second primary winding of the transformer (T 1a2 ) terminal with the same name as the switch tube (S 2 ) connected to the drain, such as Figure 32 As shown, the first secondary winding of the transformer (T 1b ) to one end of the resonant inductor (L r ), and the other end of the resonant inductor is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com