Making technology of quick-frozen raw fresh noodles

A production process, quick-frozen raw technology, applied in the direction of food science, etc., can solve the problems of difficult shelf life of products, and achieve the effects of low device cost, extended shelf life, and simple sterilization methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

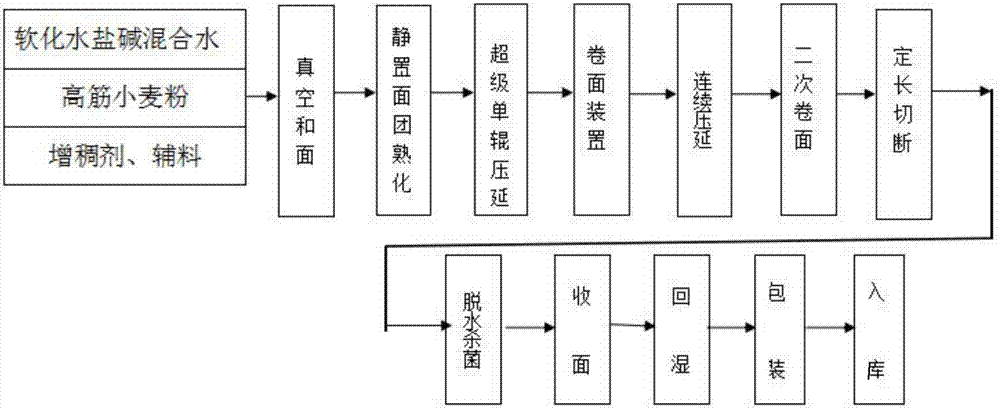

[0028] Such as figure 1 Shown, a kind of quick-frozen fresh noodle manufacturing process comprises the steps:

[0029] (1) Vacuum kneading is carried out in a vacuum kneading machine, wherein the kneading time is 900 seconds, the vacuum kneading machine pressure is 70-80kpa, and the water level in the vacuum pump water tank is 40cm;

[0030] (2) Place the dough out of the vacuum dough mixer in a sterile room and let it stand for 20 minutes to ripen;

[0031] (3) Roll the cured dough into a dough cake with a super single roller, keep the relative humidity 75-95% and keep the temperature at 18-25°C when pressing the dough;

[0032] (4) The noodle cake obtained by calendering is transferred to the noodle rolling device to be processed into noodle rolls;

[0033] (5) Repeat steps (3)-(4) one to two times;

[0034] (6) the noodle roll that step (5) obtains is fixed-length cut into noodles;

[0035] (7) Air-drying and dehydrating the noodles obtained in step (6) until no bonding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com