Method for synthesizing nano hydrated crystalline sodium silicon titanate by utilizing inorganic raw material

A technology of sodium titanate silicate, inorganic raw materials, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of CST samples containing impurity, high cost of organic silicon source/titanium source, environmental problems Problems such as serious pollution, to achieve the effects of strong chemical stability, high cost, and accelerated development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

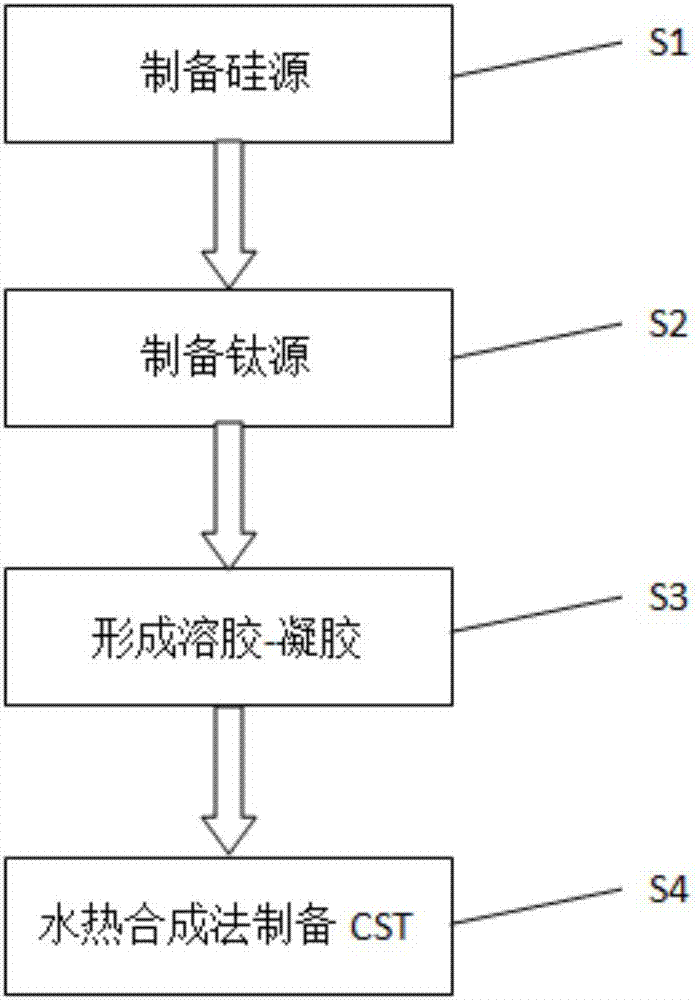

Method used

Image

Examples

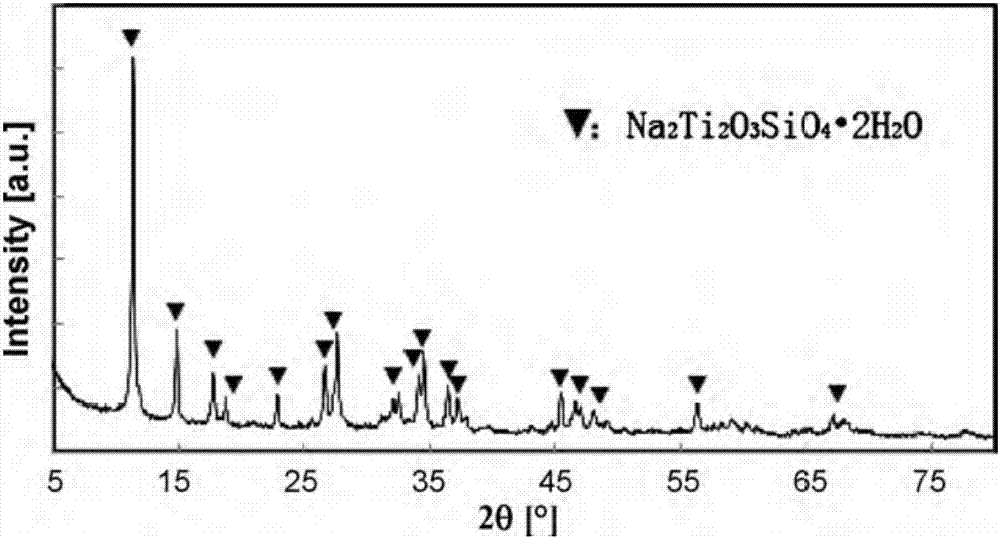

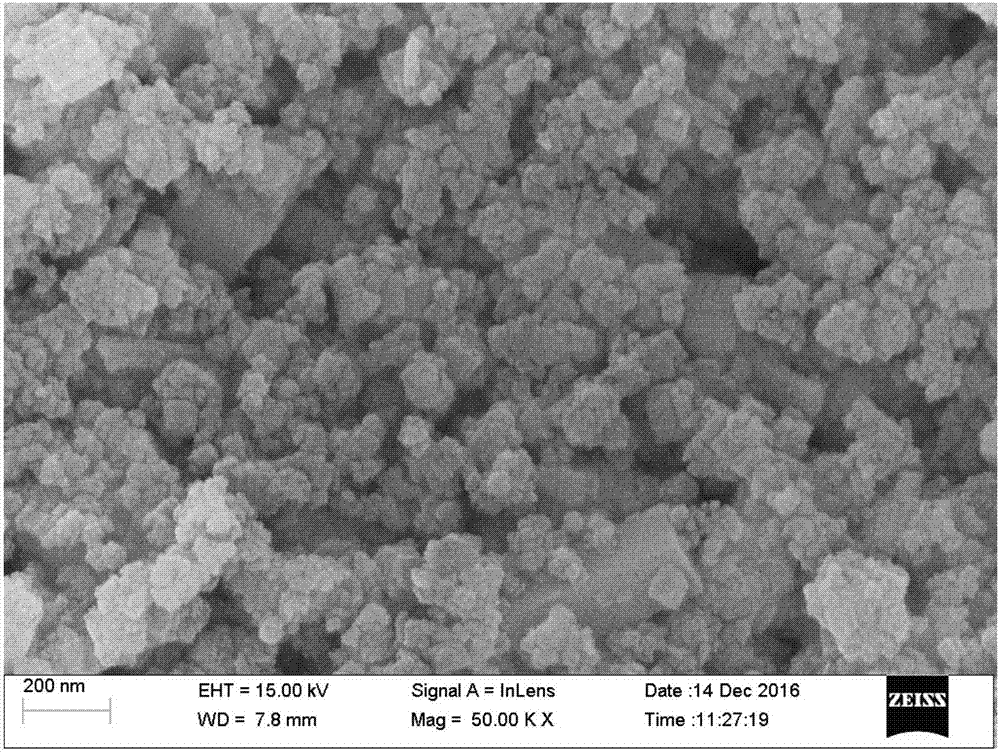

Embodiment 1

[0022] First weigh 25.3571g Na 2 Si 2 O 3 ·9H 2 O solids and 9g NaOH solids were dissolved in ultrapure water at room temperature and under magnetic stirring to prepare a 500mL solution to obtain a silicon solution with a silicon concentration of 5g / L. Then, under magnetic stirring, in a fume hood, add 5mL TiCl 4 The solution was slowly added dropwise to 20mL of absolute ethanol to obtain a uniform and transparent yellow solution, namely TiCl 4 -CH 3 CH 2 OH. Then take 50mL of the silicon solution obtained in the previous process and add it to a pressure vessel made of polytetrafluoroethylene, and take TiCl 4 -CH 3 CH 2 OH5mL. TiCl 4 -CH 3 CH 2 OH was added to the silicon liquid and stirred continuously to obtain a uniform sol-gel, and the pH was adjusted to 12.5 to 12.7. The pressure vessel was put into an autoclave, sealed, and then put in an oven at a temperature of 170° C. and heated for 7 days. After 7 days, take out the white solid obtained and filter to remove the impur...

Embodiment 2

[0024] First weigh 30.4285g Na 2 Si 2 O 3 ·9H 2 O solid and 9g NaOH solid were dissolved in ultrapure water at room temperature and under magnetic stirring to prepare a 500mL solution to obtain a silicon solution with a silicon concentration of 6g / L. Then, under magnetic stirring, in a fume hood, add 5mL TiCl 4 The solution was slowly added dropwise to 20mL of absolute ethanol to obtain a uniform and transparent yellow solution, namely TiCl 4 -CH 3 CH 2 OH. Then take 50mL of the silicon solution obtained in the previous process and add it to a pressure vessel made of polytetrafluoroethylene, and take TiCl 4 -CH 3 CH 2 OH6mL. TiCl 4 -CH 3 CH 2 OH was added to the silicon liquid and stirred continuously to obtain a uniform sol-gel, and the pH was adjusted to 12.5 to 12.7. The pressure vessel was put into an autoclave, sealed, and then put in an oven at a temperature of 170° C. and heated for 7 days. After 7 days, take out the white solid obtained and filter to remove the impurit...

Embodiment 3

[0027] First weigh 35.4999g Na 2 Si 2 O 3 ·9H 2 O solids and 9g NaOH solids were dissolved in ultrapure water at room temperature and under magnetic stirring to prepare a 500mL solution to obtain a silicon liquid with a silicon concentration of 7g / L. Then, under magnetic stirring, in a fume hood, add 5mL TiCl 4 The solution was slowly added dropwise to 20mL of absolute ethanol to obtain a uniform and transparent yellow solution, namely TiCl 4 -CH 3 CH 2 OH. Then take 50mL of the silicon solution obtained in the previous process and add it to a pressure vessel made of polytetrafluoroethylene, and take TiCl 4 -CH 3 CH 2 OH7mL. TiCl 4 -CH 3 CH 2 OH was added to the silicon liquid and stirred continuously to obtain a uniform sol-gel, and the pH was adjusted to 12.5 to 12.7. The pressure vessel was put into an autoclave, sealed, and then put in an oven at a temperature of 170° C. and heated for 7 days. After 7 days, take out the white solid obtained and filter to remove the impurit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com