Liquid crystal elastomer driving element, preparation method thereof and application of liquid crystal elastomer

A technology of liquid crystal elastomers and driving components, which is applied in the direction of liquid crystal materials, chemical instruments and methods, etc., can solve problems such as disappearance of orientation, liquid crystal elastomers are not resistant to solvents, and poor thermal response repeatability, etc., and achieve good application prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] see Figure 4 , the present invention also provides a method for preparing a liquid crystal elastomer driving element, comprising:

[0032] Step S110, adding liquid crystal molecules, molecules containing allyl sulfide groups, flexible chains, and a crosslinking agent into a solvent to form a mixture solution;

[0033] Step S120, performing a polymerization reaction on the mixture solution, so that liquid crystal molecules, molecules containing allyl sulfide groups, flexible chains and crosslinking agents are polymerized to form a crosslinked network, forming a liquid crystal elastomer; and

[0034] Step S130, performing an alignment treatment on the liquid crystal elastomer to obtain a liquid crystal elastomer driving element.

[0035] The liquid crystal molecule is preferably a mesogen with a rigid structure, a flexible chain structure with 3-6 carbon atoms, and a terminal group that can react with the flexible chain and a cross-linking agent. The terminal groups ar...

Embodiment 1

[0067] 0.45mmol of liquid crystal molecules (RM257), 0.05mmol of 5-methyl-benzotriazole (MBTA), 0.455mmol of 2,2'-(ethylenedioxy)diethanethiol (DODT) and 0.023mmol Pentaerythritol tetrakis(3-mercaptopropionate) (PETMP) was dissolved in dichloromethane to obtain a mixed solution. Oxidize 2,2-dimethoxy-1,2-diphenylethan-1-one (Irgacure651) and 1 wt% bis(2,4,6-trimethylbenzoyl)phenyl Phosphine (Irgacure 819) was added to the mixed solution, and 10 wt% of dipropylamine was dissolved in methylene chloride and added to the mixed solution to form a reactant solution. The reactant solution is quickly poured on the substrate and spread out to carry out the polymerization reaction and apply pressure to form a liquid crystal elastomer. The liquid crystal elastomer was taken out and dried to obtain a sheet-like liquid crystal elastomer.

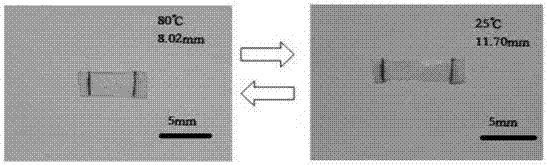

[0068] For the lamellar liquid crystal elastomer with the original length, stretching along the length direction for the first time makes its length b...

Embodiment 2

[0071] 0.45mmol of liquid crystal molecules (RM257), 0.05mmol of 5-methyl-benzotriazole (MBTA), 0.455mmol of 2,2'-(ethylenedioxy)diethanethiol (DODT) and 0.023mmol Pentaerythritol tetrakis(3-mercaptopropionate) (PETMP) was dissolved in dichloromethane to obtain a mixed solution. Oxidize 2,2-dimethoxy-1,2-diphenylethan-1-one (Irgacure651) and 1 wt% bis(2,4,6-trimethylbenzoyl)phenyl Phosphine (Irgacure 819) was added to the mixed solution, and 10 wt% of dipropylamine was dissolved in methylene chloride and added to the mixed solution to form a reactant solution. The reactant solution is quickly poured on the substrate and spread out to carry out the polymerization reaction and apply pressure to form a liquid crystal elastomer. The liquid crystal elastomer was taken out and dried to obtain a sheet-like liquid crystal elastomer.

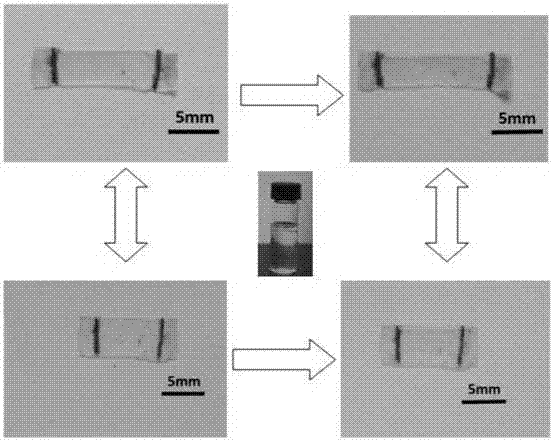

[0072] Prepare a flat plate with pin protrusions, the vertical distance from the end of the pin protrusion to the flat plate is about 5 mm. Spread th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com