Preparing method for intelligent electrochromic glass

A smart glass, electrochromic technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of harm to the body and the environment, unsuitable for industrial production, expensive raw materials, etc. Ion transport, easy-to-manipulate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

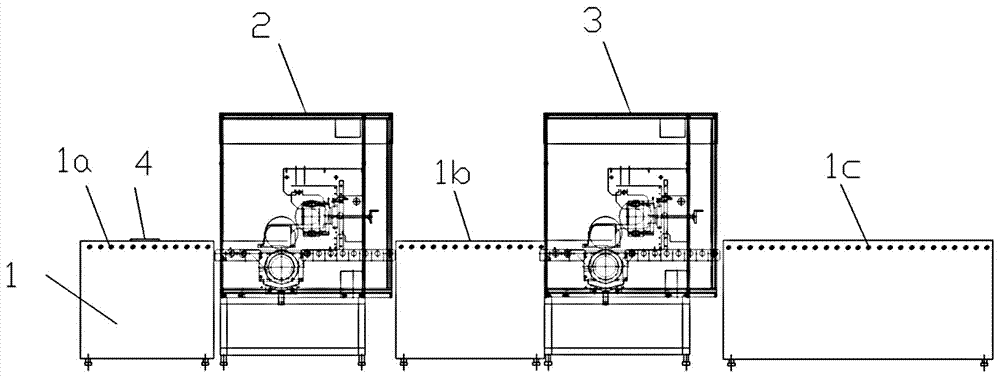

[0018] to combine figure 1 and figure 2 As shown, the present invention provides a kind of preparation method of electrochromic smart glass, comprises the following steps:

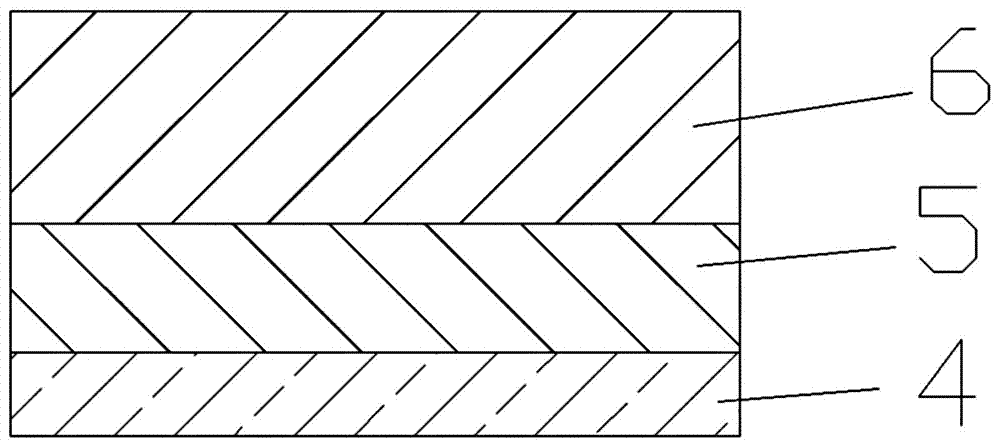

[0019] S1. Select ultra-clear glass with a thickness of 3.2mm as the glass substrate 4, and the glass substrate 4 is sent to the first liquid phase roller coating machine 2 by the first conveying roller table 1a on the loading table 1, and passes through the first liquid phase roller coating coating machine. The machine 2 coats a tin oxide-doped fluorine-doped transparent conductive film 5 on the surface of the glass substrate 4, and then enters the leveling section 1b for leveling and surface drying;

[0020] S2. The glass substrate 4 processed in step S1 is sent to the second liquid phase roll coater 3, and the tungsten oxide thin film 6 is coated on the tin oxide fluorine-doped transparent conductive film 5 through the second liquid phase roll coater 3;

[0021] S3, the glass substrate 4 processed in...

Embodiment 2

[0024] to combine figure 1 and figure 2 As shown, the present invention provides a kind of preparation method of electrochromic smart glass, comprises the following steps:

[0025] S1. Select ultra-clear glass with a thickness of 4mm as the glass substrate 4. The glass substrate 4 is sent to the first liquid phase roller coating machine 2 by the first conveying roller table 1a on the loading table 1, and passes through the first liquid phase roller coating machine. 2. Coat the surface of the glass substrate 4 with a tin oxide-doped fluorine-doped transparent conductive film 5, and then enter the leveling section 1b for leveling and surface drying;

[0026] S2. The glass substrate 4 processed in step S1 is sent to the second liquid phase roll coater 3, and the tungsten oxide thin film 6 is coated on the tin oxide fluorine-doped transparent conductive film 5 through the second liquid phase roll coater 3;

[0027] S3, the glass substrate 4 processed in step S2 enters the heat ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com